Machine Tool Builder Stresses New Strategies for Serving Moldmaking Customers

A new facility, new compact CNC and new customer service strategy for moldmaking customers is celebrated at Zimmermann open house.

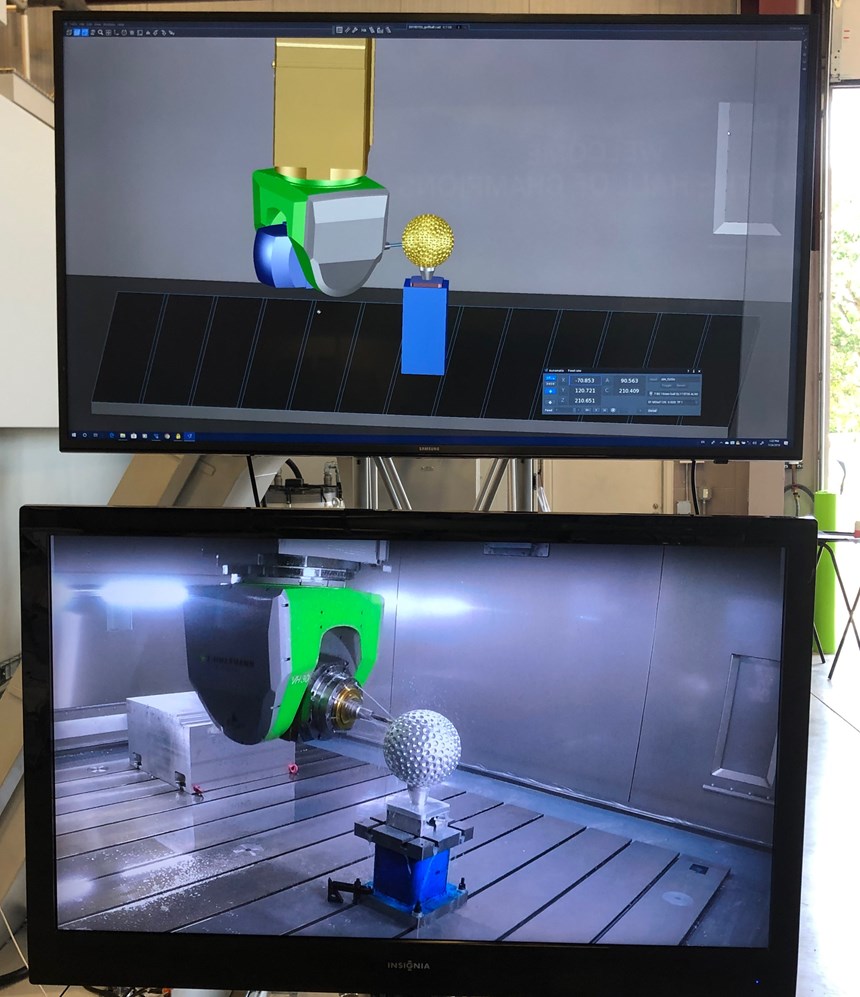

Watch as the Zimmermann FZ33c Compact Series milling machine finish machines a golf trophy, demonstrating its five-axis capabilities on a complex workpiece made of aluminum. The demo was a highlight of the company's recent open house event.

Recent trade show events like Amerimold and IMTS 2018 have put a spotlight on Zimmermann Inc.’s Compact Series of milling machines, including its FZ40 Compact and even the much anticipated FZU Compact. Now there is one more milling machine added to the company’s line, and that is the FZ33 Compact five-axis portal milling machine, which it spotlighted at its newly expanded Wixom, Michigan, facility last week.

Zimmermann pulled out all the stops at this first-ever open house in Wixom, with specially catered fare (including some German favorites), and evening entertainment the first day of the event, in addition to a live demonstration of the FZ33c and supplier partners exhibiting their products and services.

Geared for Growth

According to Lena Kiesel, marketing manager, this event’s purpose was intended to not only introduce customers to the FZ33c, but to let them know that the newly-constructed 13,200-square-foot Wixom facility now features a showroom, offices and a warehouse stocked with items like standard spindles, cables, milling heads (which Zimmermann has manufactured in-house since 2009) and other critical replacement parts. “For many years we had an office building here with a small team of representatives, but we decided it was time to expand and in December 2016 we opened this new facility,” Kiesel says. “We want to provide our U.S. customers with more accessibility to not only spare parts, if needed, but technical support and maintenance services.”

While Zimmermann can do some spindle repair work in-house at the Wixom facility, much of the repair work is still done in Germany, so the company has spares of specific, critical parts and offers an exchange program to customers to help them keep their machines running while repairs are being done.

According to Cornelius Kiesel, president of Zimmermann USA, the company currently has 15 of its Compact line machines running in U.S. customer facilities, and demand is increasing. With a growing team of support specialists across the country, Zimmermann is positioning itself to react quickly when customers call. Wixom is the U.S. headquarters, but the company also has technical sales and service representatives in Los Angeles, California, Mexico and Wichita, Kansas, in addition to three permanent subcontractors.

Compact Footprint, Large Capacity

The FZ33c is an ideal fit for mold manufacturers who machine a lot of aluminum, whether for prototyping or production molds for automotive, for example. “The FZ33 Compact is recommended for the aluminum applications and smaller workpieces,” Dominik Kohlschmidt, service engineer, says. Other materials that can be machined on the FZ33c include Styrofoam, carbon fiber and other composite materials. In certain applications, steel can be machined but only for very small stepovers or finishing. For high-speed hard milling the FZ40 is recommended. “The FZ40 Compact is what we call the big sister to the FZ33 because with steel or Titanium you need a heavier spindle, larger-sized toolholders, and so on, which we offer. The overall idea behind the Compact series is to give the customer more productivity in a smaller footprint. Every square foot of equipment space is money. We try to help the customer save on space but also get the most out of the space they are using with our machines.”

Kohlschmidt says the FZ33c features the recently introduced Heidenhain 640 Series control, but customers may also choose a Siemens 840 control from its Solution Line series. “That is the big choice with the Compact line of machines. You can choose the control, you can choose the milling head (for the FZ33c, choose the dynamic two-axis VH20 or VH30) and you can choose the size on the Y-axis,” he says. He adds that an added benefit of the Compact series is the installation time, which typically takes only four to five weeks, plus there is no need to pour a foundation. “We are also proud that we build our own milling heads so that we can offer our customers one solution. They do have a choice of spindles, though, and that includes Siemens Weiss or Fischer brand spindles.”

In addition to Heidenhein, Siemens, Weiss (A Siemens Company) and Fischer, other partner suppliers for Zimmermann machines participated at the open house, including Tebis America, Mapal, Haimer USA, Unisorb, Keller USA Inc. and Zoller. Lena Kiesel says that the theme of the open house, “The Hall of Champions,” represents the close partnerships Zimmermann maintains with each of these companies for their benefit and their customers’ as well. “We made champions the theme because the machines are made for champions; we made them, so our employees are champions; the machines are champion quality and all of our partners are champions as well,” she explains. Further supporting its theme were displays of sporting trophies that were made on Zimmermann machines. An aluminum golf ball trophy that was rough machined earlier and was being finish-machined in the FZ33c during the open house.

I asked whether the FZ40c was larger than the FZ33c, but Kohlschmidt says they are comparable. “The FZ40 is just stronger,” he says. “It has the same working area (X-axis is 98 inches, Y-axis is 118 inches and Z-axis is 49 inches). We are only trying to give customers who cut aluminum or lighter materials the option to purchase the FZ33c. Customers who want to cut both aluminum and steel will choose the FZ40c.” He says the table size and side walls are a little bit bigger on the FZ40, plus it is heavier, so it has the rigidity required to do heavier work.

Check out the slide show, above, to see more highlights about the FZ33c and the Zimmermann open house event.

Related Content

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreHow to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreRead Next

Amerimold 2019: Machining for Moldmaking, Part 1

Amerimold attendees saw many different types of machining centers, all posessing features for advancing the moldmaking process. Here are a few highlights.

Read MoreAmerimold 2019: Machining for Moldmaking, Part 2

More highlights from Amerimold with a focus on machining for moldmaking.

Read MoreBattling Robots Continue to Attract Youth to STEM-Based Learning

Heidenhain was a sponsor of the recent National Robotics League’s national competition “where education and mayhem meet.”

Read More