Amerimold 2019: New Programming Wrap-Up

There is always something new at Amerimold, and this year was no exception.

Each year, MoldMaking Technology Editorial Director Christina Fuges and the Marketing team at Gardner Business Media work to develop new and improved programming for attendees at Amerimold. This year was no exception.

What Was New?

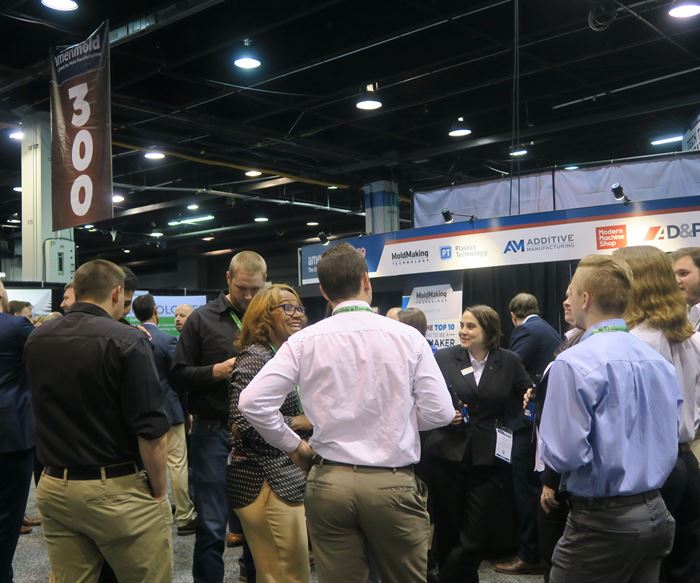

For those who were unable to join us, there were several new things to do, including attending the new 30 Under 30 Happy Hour. With workforce development always at the top of the industry’s list, it seemed natural to launch a new networking event where young up-and-coming moldmaking industry professionals could meet and get to know each other, share ideas and experiences and even ask questions of a few industry veterans who stopped by. The event proved to be a success, and MMT continues to seek out more next-generation individuals to join the group. Let us know if your shop has eager, young apprentices and employees under age 30 who are interested! (To read about those who are already involved, check out our recent features: 30 Under 30 Class of 2018: Designers; 30 Under 30 Class of 2018: Moldmakers; and 30 Under 30 Class of 2018: Human Resources Professionals.)

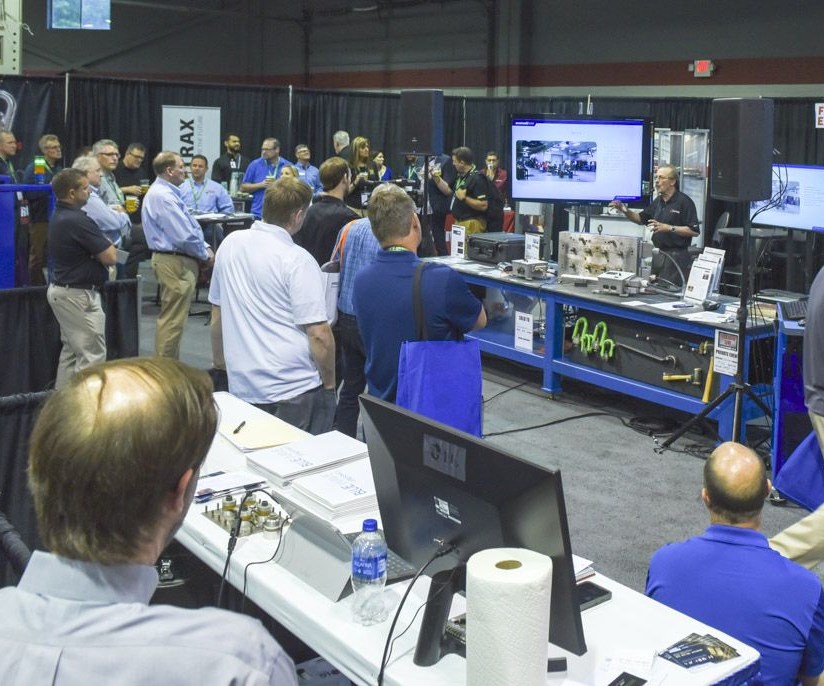

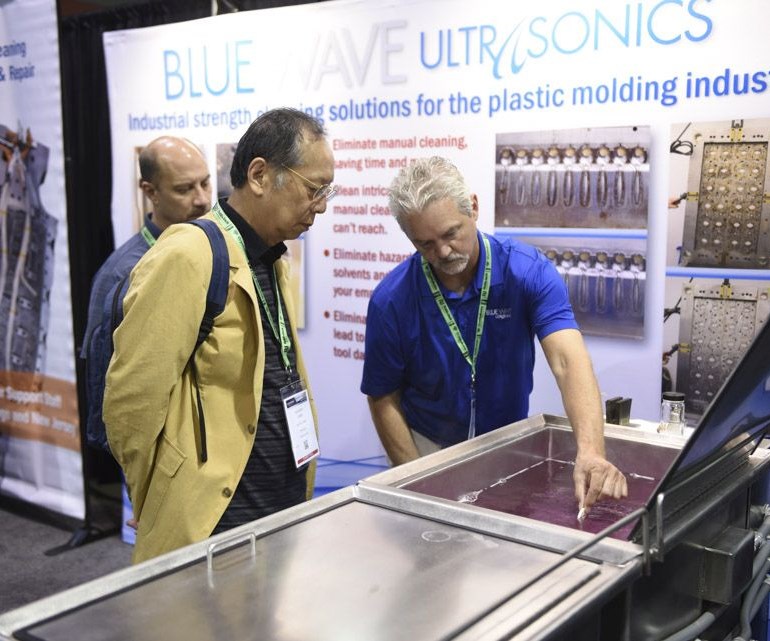

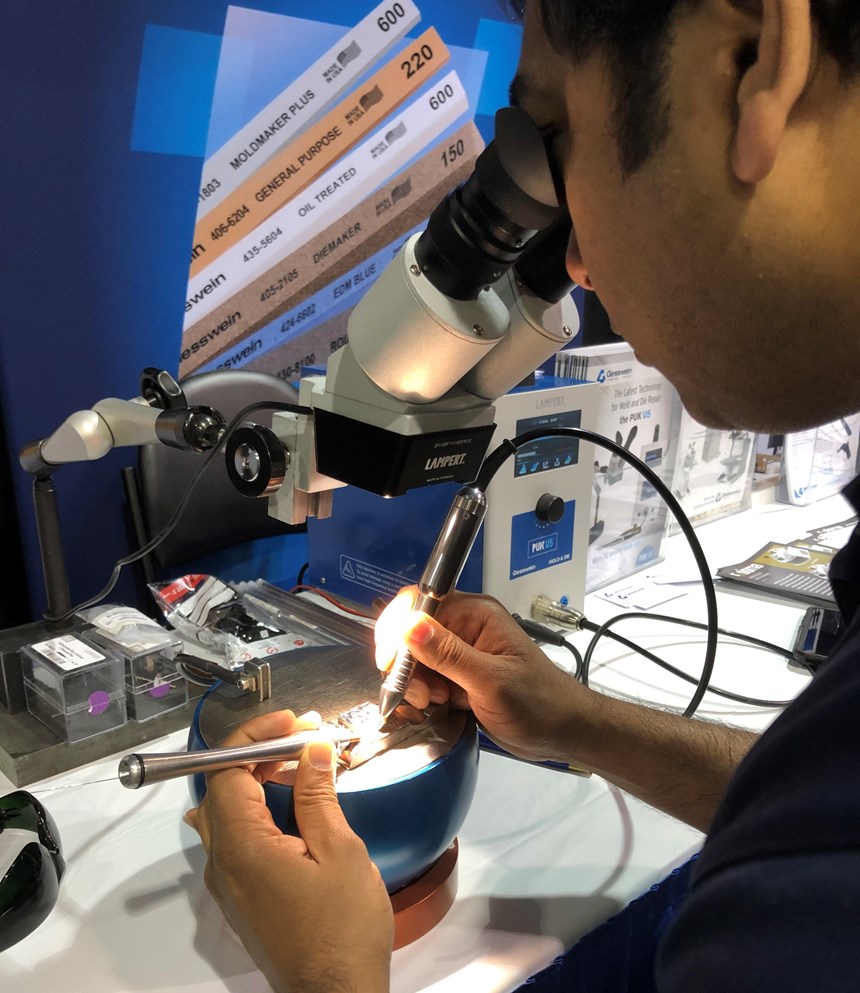

Amerimold 2019 saw two additional in-booth demonstrations for a total of six. One unique and collective demonstration was the presentation of Tool Shop Live! Elements of a New Age Repair Shop. Tool Shop Live! provided a whole new way to spotlight mold maintenance and repair because it simulated a working shop with all the essential processes that go into caring for and optimizing molds. Steve Johnson of MoldTrax led the demonstration, providing an overview of a successful toolroom setup that includes a variety of essential bench and cleaning equipment on the market today. In addition to MoldTrax, other exhibitors who took part in Tool Shop Live! were Fast Heat Inc. (custom hot runner temperature control systems), Polymer Cleaning Tech. (supplier of parts, service and repair of all brands of hot runner systems), Cold Jet (dry ice cleaning systems), Dailey Supply Inc. (lifting and material handling equipment), Die-Sep (injection mold separators and tippers, water flow and leak testers), Gesswein (mold polishing supplies and micro welding equipment) and Blue Wave Ultrasonics Inc. (heavy-duty ultrasonic cleaning systems for molds).

Speed dating? Well, maybe not, but Amerimold did launch its first-ever Sourcing Fair to help match up moldmaking companies with potential OEM customers who are seeking new sources for molds. Powered by the Reshoring Initiative, Otter Products, Scholle IPN and Toyota each had representatives on-site who met with aspiring moldmaker candidates, interviewing them to see if there is potentially a fit. Don Smith from Scholle IPN, a global manufacturer of bag-in-box and pouch-type packaging based in Northlake, Illinois, told MMT that he was “literally overjoyed” with the Sourcing Fair and that it “far exceeded” his expectations. The event yielded 16 solid shop leads, he says, and “provided outstanding results for Scholle IPN.” Paul Freer from Toyota was also pleased with the results and commented that the combination of appointments with moldmakers and walking the show floor allowed them to connect more fully with candidates versus just walking the show in search of vendors. Toyota walked away with several new leads, he says.

These are some of the new programs introduced at Amerimold that everyone can look forward to experiencing again next year in Novi, Michigan, June 10 – 11, 2020. Join us!

Read Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreOvercoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More