MMT Blog

Injection Molds and Integrated Solutions Through Ambition and Innovation

Jordan Robertson, VP, Business Development and Marketing for StackTeck discusses various mold technologies to improve efficiencies in automation, cooling, lightweighting and sustainability.

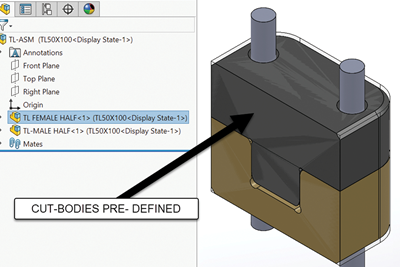

WatchMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

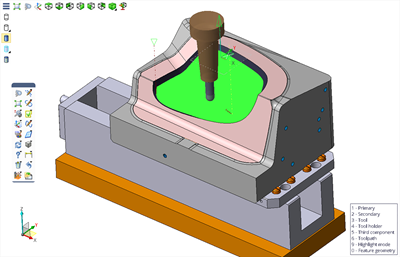

Read MoreHow to Customize an Interoperable Software Solution for Your Moldmaking Process

A connected software solution streamlines the moldmaking process by providing a unified source of design data, enhancing efficiency and reducing errors, with five key steps benefiting from this integration.

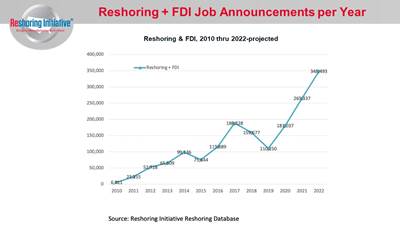

Read MoreDecoding Reshoring: Motivations, Challenges and Technological Influences

Harry Moser, founder and president of the Reshoring Initiative, sits down for a Q&A on the motivations behind reshoring decisions, offering insights into economic, strategic and regulatory considerations.

Read MoreThoughts on VR's Immersive, Interactive Mold Design Training

A virtual reality (VR) application transforms training from passive to active learning by immersing users in a dynamic virtual space.

Read MoreContraction in Moldmaking Activity Slowed Again in March

While still contracting, March’s moldmaking index is back on track, albeit at a slower pace, to potentially cross back over into expansion territory.

Read MoreAligning Your People Strategy with Your Business

Editorial Advisory Board member Marion Wells, founder of Human Asset Management discusses the why and how of developing a talent plan.

WatchVIDEO: Standardization and the Future of Moldmaking

Progressive Components President Glenn Starkey discusses their focus on standardization and the future of moldmaking (it’s here to stay!).

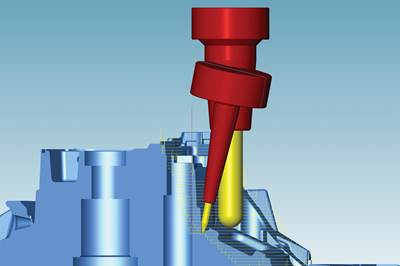

WatchHow to Implement Five-Axis Mold Machining for Higher Productivity, Versatility

Understanding the basics of five-axis capabilities justifies the investment, but exploring all the multi-axis machine benefits and approaches enhances the return on investment.

Watch2024 AMBA Conference Taught Me How to Elevate, Engage and Evolve

I returned home with a wealth of inspiration and instructions, including the importance of leaning into discomfort, having difficult discussions, delegating more, letting others shine and understanding the difference between a promise and a goal.

Read More8 Ways the Plastics Industry is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read More

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)