Latest Issue

April 2024

Digital Edition

In this Issue

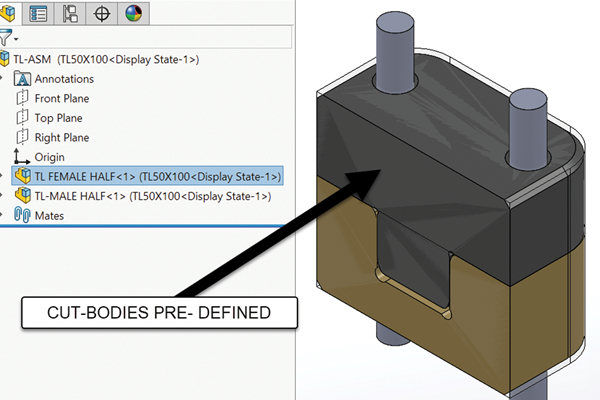

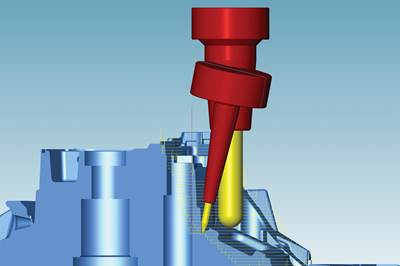

How to Customize an Interoperable Software Solution for Your Moldmaking Process

A connected software solution streamlines the moldmaking process by providing a unified source of design data, enhancing efficiency and reducing errors, with five key steps benefiting from this integration.

Read More

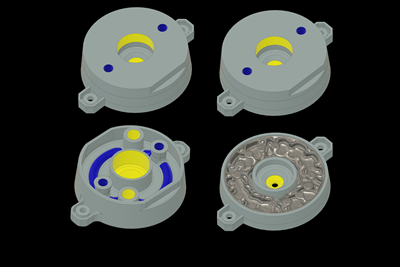

How to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

Read More

Deliberate Mismatches for Easier Mold Manufacture and Improved Part Appearance

Basic principles for applying deliberate mismatch in the area between the core and cavity and between two matching plastic parts.

Read More

ERP Empowers Mold Builder to Increase Speed, Efficiency, Accuracy

Highly integrated but easy-to-use ERP system helps Delta Mold Inc. increase unattended hours, uptime, productive labor hours and improve mold delivery times.

Read More

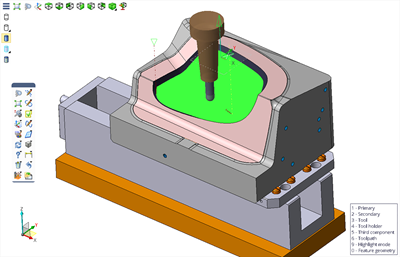

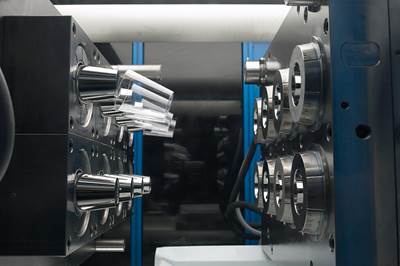

How to Implement Five-Axis Mold Machining for Higher Productivity, Versatility

Understanding the basics of five-axis capabilities justifies the investment, but exploring all the multi-axis machine benefits and approaches enhances the return on investment.

Read More

.png;maxWidth=300;quality=90)