Texturing, Engraving Service Supports Mold Builders, Plastics Industry

NPE2024: Custom Etch brings its knowledge in laser texturizing, engraving, marking and labeling to mold builders and molders via new technology investments.

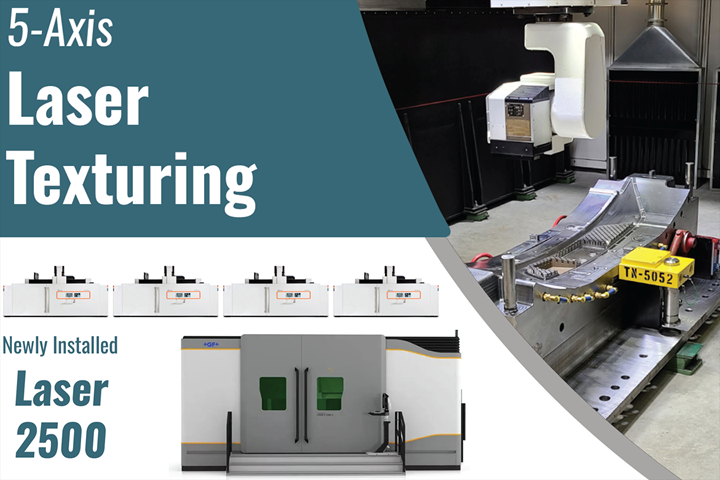

Custom Etch Inc. is a texturing and engraving specialist, with its core business servicing mold builders and the plastics industry. Considering itself as one of the larger five-axis laser job shops in the U.S. — more than 10 machine units are installed at its shop — Custom Etch strives to give customers the best turnaround time and pricing, keeping up with the constant evolution of laser technology and new hardware, which has been implemented to handle any shape and any size mold with high-speed 3D scanners with multiple laser sources.

Custom Etch produces texturizing, engraving, micro-structuring, marking and labeling of 2D geometries right through to complex 3D geometries. It also maintains capabilities for mold repairs, chemical texturing and offers a process to apply patterns to an extrusion roll.

The company recently increased capacity to meet high demand. In addition to its current lineup of technology, which it says will service any texture needs, Custom Etch invested in a Laser P 2500 U laser texturing machine from GF Machining Solutions, which offers increased accuracy and repeatability, reduced hot spots and other advantages, in addition to meeting Custom Etch’s requirements in terms of speed and size. This new unit was put into service and added to the company’s laser portfolio in January 2024.

Related Content

-

Use AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

-

Hydraulic Gating Cutting Reliably Separates Molded Parts

NPE2024: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

.png;maxWidth=300;quality=90)

_970x250 4.png;maxWidth=970;quality=90)