September 2005 Issue

September 2005

Features

Featured articles from the September 2005 issue of MoldMaking Technology

Transforming a Modeling Tool Into a Collaborative Environment

Simultaneous product development and manufacturing represents a breakthrough in design team interaction—streamlining mold design.

Read MoreGive and Take

Staying on top of the latest moldmaking trends and technologies is the only way to survive in this ever-changing, increasingly competitive moldmaking marketplace.

Read MoreDefining the Data Barrier, Part 2: Standardizing Maintenance Terminology

Changing a mold maintenance culture from reactive to proactive requires more effort than just installing an electronic database and turning the dogs loose.

Read More

Three Ways to Minimize Downtime in Your Shop Using Engineered Air

To ensure the most reliable, engineered air possible, one must consider system redundancy, accessibility and maintenance, and technological advances in control and monitoring.

Read More

How to Select and Use Your Vertical Machining Center

Competitive shops need to consider the true capabilities of their VMCs to achieve a high level of accuracy and surface finish.

Read MoreSeven Reasons to Say “NO” to New Business

Make sure potential customers match your ideal customer profile before you take them on.

Read More

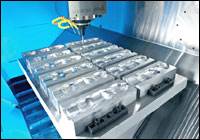

Taking Control of Finer Surface Finishes at Higher Speeds

An increased interest in five-axis machining—coupled with advances in controls and cutting tools—add up to finer surface finishes at higher speeds.

Read More

Developing an Effective Machine Tool and Spindle Service Program

To get ahead of the competition your shop must use and maintain its available resources by achieving a high level of overall equipment effectiveness

Read MorePeople: The Most Challenging Part of Automating a Mold Shop

A shop won't get far, if attention is not paid the people side of making the automation transition.

Read More