Developing an Effective Machine Tool and Spindle Service Program

To get ahead of the competition your shop must use and maintain its available resources by achieving a high level of overall equipment effectiveness

In today's highly competitive world, running an efficient shop can make or break a moldmaker's success. That is why it is so important to develop a machine tool and spindle service program that effectively manages all available assets.

Increasing productivity does not always require the latest and greatest in machine tools. And with competitors popping up all over the globe, the newest and fastest tools cannot guarantee that a plant will keep the competitive edge. Getting ahead of the competition means utilizing and maintaining a plant's available resources by achieving a high level of overall equipment effectiveness (see Chart 1, below), which is a performance measurement comprised of three factors: (1) asset availability; (2) production rate; and, (3) quality level.

Within the moldmaking industry, there are few occasions where a single machine component has a direct and significant impact on all three of the factors of overall equipment effectiveness. However, a machine spindle is an exception. Spindles affect asset availability, production rate and quality level.

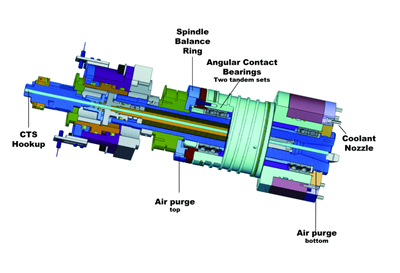

Normal use of any moldmaking machine will cause wear and tear on its parts, and spindles are the components that receive the majority of this wear. Spindles need to be run at the right speeds and feeds to keep wear and tear to a minimum and increase production rates and quality. Spindles also need maintenance at varying intervals, based on the length and design of their operation. There is technology available today that allows a moldmaker to monitor a machine's time of operation and condition of its components, while suggesting the most efficient speed and depth of feed.

Overall Equipment Effectiveness

Employing this technology into a machine tool and spindle service program is the key to achieving overall equipment effectiveness. The right service program should utilize all available assets. It should keep a spindle running in peak condition, which allows it to maintain a high level of quality and production, through regular maintenance. But if a spindle is serviced too often, money is lost on maintenance fees and the spindle is not used to its full potential. A good service program should make provisions for both maintenance and repair, while taking into consideration the specific operational information of each individual spindle so that service is performed according to its usage. And repairs can be predicted if the spindle's condition is constantly monitored.

With such advanced technology available today, sadly, some mold shops' programs for maintenance and repair still lack the necessary provisions for proper service. The following five examples—ranging from nearly ludicrous to highly advanced—demonstrate the evolution of the machine tool and spindle service program.

1. The Emergency Program

The emergency program is the panic button of repair programs. When an important spindle has broken down, sometimes the high cost of that spindle not operating necessitates an immediate response. A moldmaker who abides by the emergency program will have the spindle repaired quickly and at all costs. There are horror stories of emergency program practitioners renting a Lear Jet at the last moment to have a broken spindle flown cross-country for repair. Add the costs of the jet to the high-priority service fees paid for immediate service. While minimizing the spindle's downtime, the cost of the emergency program also minimizes its practicality.

2. The “First In, First Out” Program

This is the no program program, where no arrangements are made for spindle maintenance, and spindles are simply brought in to a service center for repair when they break down. This program also is impractical, especially if the spindle is of any importance to the plant in which it operates. The first in, first out program can lead to extended periods of downtime, since the spindle is serviced in the order it was received. While repair is performed at normal service rates, no particular priority is given to the order. This means that a spindle could be out of commission for weeks, even months.

| The Total Condition Review | |

| When a service program does indicate the need for a service call, it is important that this maintenance is thorough. The service should include a total condition review, up to and including filing event information in a master database for use in similar operations company-wide. | |

| 1. General visual inspection |

12. Stator and rotor inspection |

| 2. Incoming function test |

13. Bearing journal control |

| 3. Motor and electrical check |

14. Tool nose and shaft control |

| 4. Drive component inspection |

15. Repairability review |

| 5. Spindle disassembly |

16. Shaft balancing |

| 6. Clamping system inspection |

17. Encoder adjustment |

| 7. Bearing inspection |

18. Spindle run-out control |

| 8. Coolant permeability check |

19. Spindle clearance control |

| 9. Lubricant inspection |

20. Spindle run-in |

| 10. Sealing inspection |

21. Vibration control |

| 11. Sensor control | 22. Database filing and feedback forms |

3. The Scheduled Program

The scheduled program is the mark of true mediocrity. Given the spindle's past maintenance records, a regular maintenance schedule is set for the spindle. The upside to this program is that it gives ample attention to keeping the spindle in good operating condition; however, it does not take into account the spindle's fluctuating hours of operation, environmental considerations or even whether or not the spindle needs to be serviced. The majority of scheduled programs tend to be too conservative in determining the length of time a spindle can operate before it requires maintenance. While the spindle is usually kept in premium operating condition, time and money may be lost on unnecessary service.

4. The Spindle “Hotel” Program

The spindle hotel program takes preventative measures to the extreme. Coined from a European term, the spindle hotel is an inventory of extra replacement spindles kept on site or at a designated repair facility. When one spindle breaks down, an identical spindle is retrieved from the hotel and exchanged for the broken one. The spindle hotel program works well in that downtime is limited to the actual exchange of spindles, but the effectiveness of this program comes with the high cost of keeping such a selection of replacement spindles available. The amount of capital tied up in the hotel could outweigh its convenience, and for that reason, the spindle hotel program may not always be the best choice.

5. The Asset Efficiency Optimization Program

The asset efficiency optimization program essentially integrates a company's design, manufacturing and preventative maintenance efforts. The asset efficiency optimization program employs machine tool sensors that collect and evaluate vibration and machinery usage data. The data is recorded on a scheduled basis, so potential problems are predicted and repair/maintenance can be performed accordingly. The asset efficiency optimization program allows plant management to closely monitor the conditions of spindles and determine the most effective way to run their machines. This program does require an initial investment of funds for sensor equipment. But since problems are predicted, the program saves money by eliminating unnecessary routine maintenance and unanticipated downtime. Plants that employ an asset efficiency optimization program experience reductions of 35 percent in spindle repair costs, seven percent in scrap rate and 20 percent in their maintenance budget. Companies that use this program also experience an average spindle life extension of 25 percent and a 4.7 percent increase in uptime

In the manufacturing world of today, the competition is no longer just a company down the road, or even in the same hemisphere. Even if the competition was close by, there's no guarantee that a newer, faster machine will keep a facility ahead of the rest for long. And there also is no guarantee that capital funds will be available to buy that new machine when it is needed. Employing a machine tool and spindle program that monitors the machine and provides feedback for optimal performance will give a moldmaking facility an advantage. This advantage can be obtained regardless of the age of the machine.

The efficiency of an asset is best optimized through the

application of a well-planned maintenance strategy, improved work processes and thorough use of operator input. To achieve reliability, quality and performance, shop management must develop a deep understanding of the role that each aspect of the design, operations and maintenance programs plays in optimizing plant performance in relation to reliability targets.

The most important factor to take into consideration when choosing a spindle service program is the goals of the plant. A program that has proven itself most effective across the board will not work if it does not meet the specific requirements of the moldmaker. However, by closely monitoring the machines' performance and constructing a service program accordingly, any moldmaker can make a machine tool and spindle service program work for their plant.

References

1 Data from SKF study.

Related Content

MMT Chats: Acquisition Trends and Lessons for Mold Builders

Jim Berklas is a former full-time M&A lawyer for several of the largest private equity firms in the country and has 25 years of M&A experience and 200 closed transaction. Today, he is founder and M&A Leader with Augmented Industry Services. He joins me for this MMT Chat on mergers and acquisitions trends and strategies within in the mold manufacturing industry. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreRead Next

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)