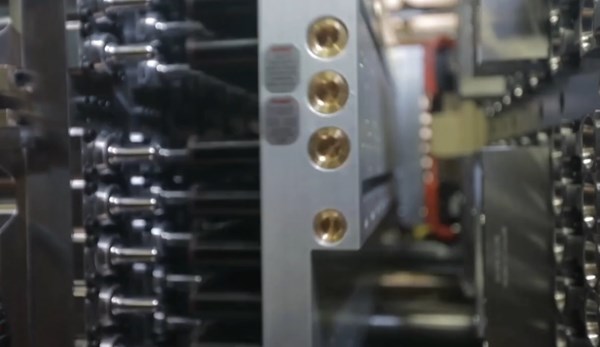

A Look at Self-Cleaning Mold Technology

A self-cleaning mold feature helps to eliminate hundreds of hours of mold maintenance a year, while reducing the risk of damage to the mold and making the cleaning process safer.

Overcome the contradiction between cycle time and mold maintenance with self-cleaning mold technology. Self-cleaning can eliminate up to 400 hours of maintenance time per year, which results in 5% more production time,” says Nicolas Rivollet, Husky’s Director of Business Development. Self-cleaning is a push-button that uses controlled flash of the tool to collect and remove dust built up in the vents. Completely automated, totally reliable, and consistent, self-cleaning does not require an operator to go inside the machine, and can be performed as often as needed as there is virtually zero time penalty on production. Click here for an instructional video.

Related Content

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

-

How to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

-

Understanding Manifold Thermal Expansion

Molders, mold builders and repair technicians must fully understand thermal expansion to ensure they don’t damage critical seals during manifold repairs or routine cleanings.