Simcenter Testlab Enables Better Usage of Test-Based Data

Siemens Digital Industries Software announces the latest release of the Simcenter Testlab software suite.

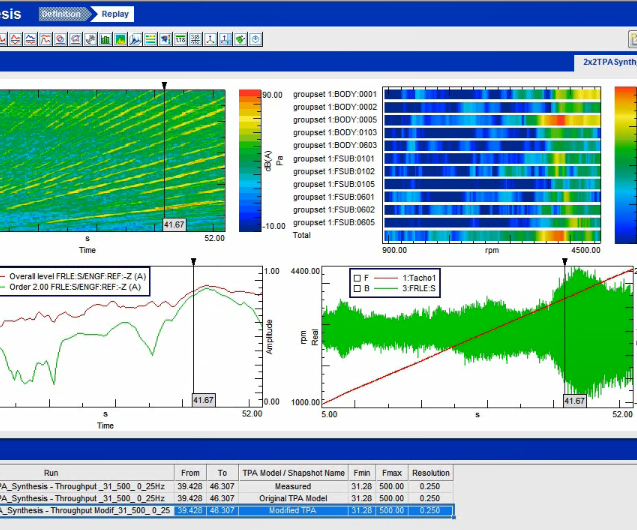

Siemens Digital Industries Software announces the latest release of the Simcenter Testlab software suite, designed to help engineers make quicker decisions by increasing productivity in testing scenarios through new capabilities. It has been specifically designed to offer test teams all the capabilities they need to innovate smart products under tight schedules. Now, test-based data is used not only for validation and certification, but also earlier in the development cycle, during simulation and design.

The latest version introduces brand new technologies, as well as a series of functional enhancements. The version includes advancing model-based development, model-based system testing uniquely closes the loop with simulation and enables system validation based on a combined physical and virtual test. It has component-based transfer path analysis predicts full-system noise, vibration and harshness (NVH) performance earlier in the development cycle by combining component models and measurements. In response to NVH challenges in vehicle electrification, the latest release covers the new minimum noise standards for Acoustic Vehicle Alerting System, introduces active sound design to create brand-specific sounds, and enhances sound quality engineering with high-quality interactive audio and video replay. The latest version of Simcenter Testlab adds numerous extensions to Simcenter Testlab Neo software and to the other Simcenter Testlab solutions. It sets higher standards in critical focus areas, such as greater productivity, increased confidence, better insight and easier collaboration, maximizing the benefits of using the digital twin.

Related Content

-

Initial Pellet Contact is the Screw

This summer, let’s get back to the basics. For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. This week: the machine’s reciprocating screw, which is often misunderstood and applied to the process incorrectly.

-

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.