Shell Mill Supports Variety of Rough Milling Strategies

The Ceratizit MaxiMill 251 is optimal for pocketing, mold and die roughing, face milling, slotting and helical interpolation of holes.

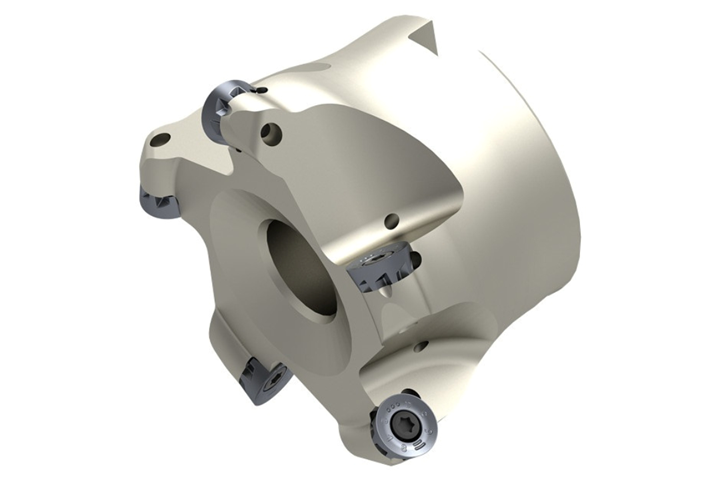

The MaxiMill 251, presented by Ceratizit is a shell mill, also known as a button cutter, that offers various rough milling strategies. Utilizing a stable round insert, the positive mounting position provides a soft cutting action, giving lower cutting forces for a smooth cut.

MaxiMill 251 features six face-mounted inserts, with a 2" cutting diameter (max is 2.5") and a 0.24" maximum depth of cut. Applied in a variety of applications, the MaxiMill 251 can be used for pocketing, mold and die roughing, face milling, slotting and helical interpolation of holes. It is also commonly used in aerospace and energy sectors, as it works well in high-temperature alloys, steel and stainless steel. In addition, the MaxiMill 251 is an optimal cutting solution for unstable pieces, older and lighter machines that cannot achieve the performance needed of high-feed cutters, as well as multi-axis machining.

Related Content

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

End Mills, Drills, Inserts and More for Mold Building Needs

This list of cutting tool-related products that MMT editors have recently published provide readers a good look at what is being offered in the industry for their everyday operations.

-

Modular Tooling Systems Enable Versatility in Hole-Drilling Operations

The versatility of replaceable cutting edges offers users the ability to adapt to varied operations.

(4).png;maxWidth=300;quality=90)