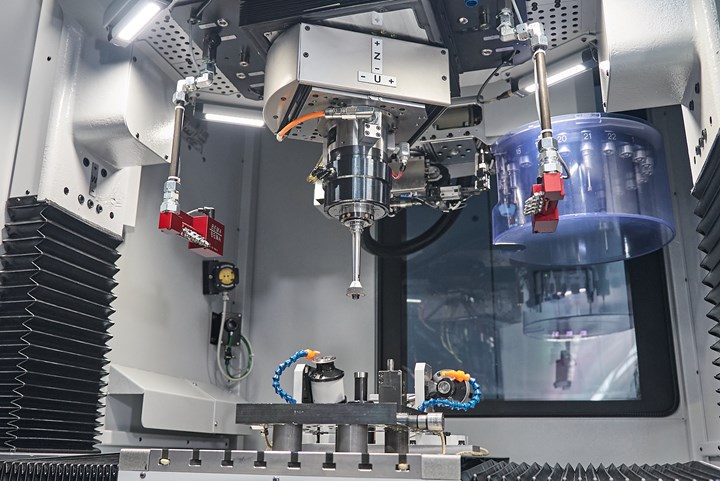

Jig Grinder for Mold and Die Increases Rigidity for High Precision

The Hardinge Hauser 2000 combines grinding and hard milling features under one machine, featuring a dual-frame design, elimination of transverse forces and more to ensure highly accurate machining capabilities.

Hardinge highlights the Hauser 2,000, a newly debuted jig grinder for mold and die that combines highly accurate grinding with hard milling features. It enables a high finish (0.01 Ra), an ideal feature for some of its customers who use it for injection molds.

The six-axis machine is a dual-frame design, increasing the rigidity of the grinder, and therefore ensuring high precision; its electrical connection, heat exchangers and other systems are also made separate from the main cell to reduce vibrations and ensure optimum quality. Moreover, no transverse forces are created — the prerequisite for ultra-high geometric precision machining, according to the company. Its layout is said to aid in thermal stability.

X, Y, C, U, Z and W axes are CNC controlled, as a standard, with Fanuc 30i, and a maximum of 47-mm U-axis. The machine also features hand-scraped guideways in the X- and Y-axis. Atypical to these types of systems is an exchange grinding spindle. Proven technical features include automatic taper grinding, automatic grinding tool changer (ATC) (with 22 magazine positions) and automatic pallet changer (APC). Optimization in stroke speed and stroke frequency is said to lead to reduced grinding cycle time.

Related Content

-

Automated Grinding Machines Yield Tighter Tolerances and Save Resources

National Tool & Manufacturing Co.’s integration of two Ziersch grinding machines into its shop floor enables the tight tolerance demands from its customer base and simultaneously frees up manual resources for other projects.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

How to Overcome Common Deep-Hole Drilling Challenges

Producing deep holes effectively and efficiently is a challenging application that requires cutting tool solutions that offer predictable cutter life, accurate surface finish and repeatability.