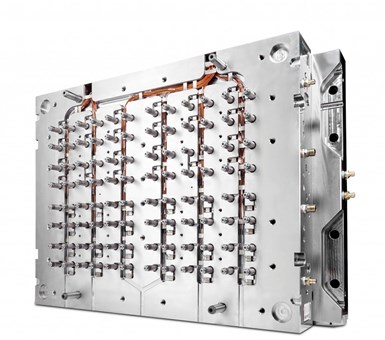

Hot Runner Series Ideal for Molding with Challenging Resins

Mold-Masters/Milacron offers its latest advancement in hot runner technology delivering peak performance and precision.

Mold-Masters/Milacron offers its latest advancement in hot runner technology delivering peak performance and precision. The company’s Summit series is ideal for molding with challenging abrasive, corrosive, shear and temperature sensitive resins, as well as medical, personal care and technical molding applications. The series features nozzles with exceptional process control and repeatability, producing high quality parts and minimizing scrap. The full stainless-steel construction helps prevent contamination defects from premature wear and extends service life. With iFlow manifold technology, the series provides extensive flexibility for design optimization, patented melt flow geometry, flow path options and runner shapes, and reduced stack height. Brazed heater technology optimizes heat transfer, offers system thermal balance and eliminates spare heater costs.

Related Content

-

Ejector Pin Selection Guide

A review of materials, treatments and coatings to help determine the proper pins for optimized plastic part ejection.

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

-

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.