RJG Partners with Southern Union State Community College

SUSCC’s newly updated classroom and lab space will allow RJG to provide students with the latest in hands-on training technology.

RJG (Traverse City, Michigan) has partnered with Southern Union State Community College (SUSCC, Wadley, Alabama) to bring RJG’s injection molding training to the Center for Integrated Manufacturing.

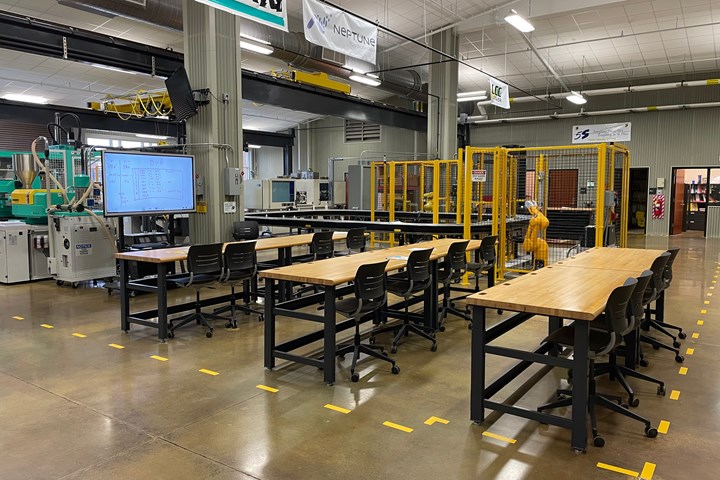

SUSCC’s newly updated classroom and lab space will allow RJG to provide students with the latest in hands-on training technology. There are currently three fully equipped RJG injection molding machines in the facility along with a large variety of auxiliary equipment and robotics.

Courses taught in this facility will include Fundamentals of Systematic Injection Molding, Decoupled Molding Workshop, Master Molder I and II, Advanced eDART Training and more. Courses are led in-person by experienced RJG instructors.

“We are thrilled to have this opportunity to work with such a prestigious center for continued manufacturing education,” says Shane Vandekerkhof, director of training and consulting at RJG. “We always strive to offer our students positive environments equipped with the latest technology to promote growth and learning that they can immediately put to use.”

“We are excited to partner with a company as highly regarded as RJG,” says SUSCC’s president Todd Shackett. “They are renowned as the premier systematic injection molding company in the industry, and their expertise will help bring our program to the next level. I am looking forward to seeing our students and industrial partners benefit from this opportunity.”

Related Content

-

Considerations for Assessing Robotics Requirements

For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. Knowledge of part de-molding, end-of-arm tooling construction, part defects caused by the mold-robot interface and available automation options is key for suppliers looking to add greater value.

-

Getting You to Think in Plastic First

For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. The final step is to take the lessons learned from this series and figure out how to impart them to the future moldmaking/molding workforce.

-

Preparing for Takeover Tooling

For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. With the right preparation, moldmakers can insulate themselves from takeover tooling crises and add greater value to the molder.