Conformal Cooling: Not Just Faster Parts but Better Parts

EVCO Plastics has been offering DMLS conformal-cooled inserts for years and like many shops today, they outsource this work to mold builders who have expertise in DMLS.

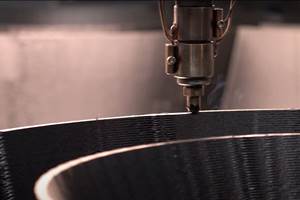

EVCO Plastics (DeForest, Wisconsin) has been offering DMLS (direct metal laser sintering) conformal-cooled inserts for five years. Like many shops today, they outsource this work, but not to local job shops with metal printers that are not tailored to the injection molding industry. Evco uses mold builders who have expertise in DMLS.

When Evco contracts out the building of a conformal cool insert, the shop is making them a blank. It's not a finished piece. For example, if it’s a core, Evco will design the mold and conformal-cooled insert with the help of the outside vendor." Then once they get the blank back, they finish machine for accuracy. “It’s important to realize that it is not a finished piece coming out of the machine, although they are pretty accurate,” Evco Plastics Design Manager/Tooling Engineer Mark McDonald says.

The key to selling this technology to customers, according to McDonald, is getting beyond the theoretical and proving out a conformal cooled-insert against a traditionally manufactured insert. For example, a long-time customer of Evco ordered a rebuild of a one-cavity mold they ran for years and requested conformal cooling. To prove out the benefits of conformal cooling, Evco built the inserts (core, cavity, slides) to put into this new mold where the customer was having cooling problems, and then tested the cycle times. This revealed the savings conformal cooling offered. It gave them the data they were looking for to prove conformal cooling improves cycle time. This particular tool’s cycle time went from 32 seconds down to 17 seconds due to better cooling.

McDonald stresses that the advantages of conformal cooling go beyond cycle time; it also improves part quality, CPK values, part flatness, and sink. For example, an area in a mold that does not cool well will result in sink, which causes part warpage. “Conformal cooling is not perfect for everything, but it can help in all of those areas,” McDonald says.

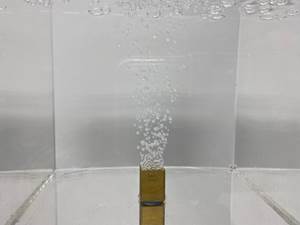

However, he cautions that when you build conformal cooling channels, be very careful of your water. “If something gets plugged up on a cooling channel in a conventional insert, you can remove a plug, drill it out and get back up to speed. However, with conformal cooling lines that are at crazy configurations, that process is not an option anymore. Conditioned water is a must. It has to be a controlled system,” McDonald says.

The key to staying up on all of the latest technology involved with conformal cooling is building a network of capable shops and establishing a solid supply chain, according to McDonald. “We do have plastic printing in-house, but we still can't do it all. There are so many variations today. For example, a company wants to simulate a two-shot part. 3D printers exist that can do that. We don’t happen to have one, but I know a guy in Milwaukee who does,” McDonald says.

Related Content

Variable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

Read MoreHow to Prepare for the Rise of AM in Moldmaking

Mold builders should consider investing in three key areas to take advantage of the opportunities 3D printing presents.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)