What if Metal Follows the Same Path as Plastic?

It will, says Directed Manufacturing. This company sees metal additive manufacturing becoming as much of an established technology for final part production as plastic additive manufacturing is now. It expects to buy more metal additive machines in anticipation of the work that’s coming.

Today, 99 percent of the time on Directed Manufacturing’s five plastic additive manufacturing machines is committed to making production parts. Those parts include fuel tanks, enclosures, winglets and other components for unmanned aircraft. They also include various specialized surgical instruments and surgical alignment guides. These selective-laser-sintered products are all complex, high-value and low-volume—perfect for additive manufacturing. In the past, additive processes were associated with prototyping. Now, except for that remaining 1 percent of machine time, this is no longer the way that Directed’s customers view this capability.

But that’s plastic. The Austin, Texas-based additive manufacturing contractor uses 3D printing processes to make metal parts as well. Seeing additive manufacturing accepted for plastic part production took years, perhaps even decades. Materials and processes had to be proven, the company says, and designs and designers had to adapt to the geometric freedom that additive manufacturing makes possible. In metal, this acceptance is coming faster than it did for plastics, but it has not yet been won. The tipping point might come this year. To date, most of the company’s additive metal capacity has been devoted to product development, but some of those developed products have now been committed to final manufacturing on the same additive machines. The company expects to buy more additive metal equipment to meet the growing demand.

Those additive machines will probably come from Renishaw. Last year, Directed became the first U.S. commercial user of the selective laser melting machine now offered by this company (which is known for technology that relates to CNC machining). Renishaw’s additive manufacturing system is open architecture, which allows users such as Directed to develop and customize machine parameters for new materials specified by their customers. Directed’s managers say that this feature, and Renishaw’s promise of assistance in developing parameters for new materials as needed, was a major factor in their decision to choose the machine. Then, once they had it, they say that another valuable feature proved to be the machine’s 12-inch build height. Three other additive metal machines at Directed all have a maximum build height of 10 inches. The 2-inch difference might not seem like much, but the work envelope on these machines often proves to be the crucial factor that determines whether a part can be additively produced.

Cost Savings

Alex Fima and James Hockey are part of the technical and business development and sales staff at Directed, and Alex Ramirez manages the production floor. They say that not only is metal additive manufacturing moving from prototyping to production in the same way that plastics did, but metal additive technology is making this transition faster. The fact that plastics blazed the trail is just one of the reasons for this. Another is that the buyers of metal parts are more likely to be making an established product that faces strong pressures for cost reduction. In the right applications, additive manufacturing delivers these needed savings.

Aircraft engines are an example, Hockey says. The potential for cost improvements within the engines’ traditional production processes has largely been explored. The low-hanging fruit has been picked. Engine makers are therefore looking to non-traditional methods in the hope of significant cost savings. Potentially, additive manufacturing can provide these savings in multiple ways.

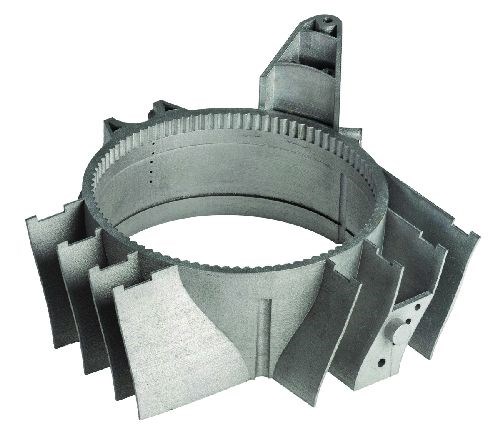

One is through reduced material use and part weight. Much of the product development that Directed performs involves refining and redesigning parts to try to make them as material-efficient as possible. Parts produced through additive manufacturing can be highly intricate. They also do not have to be solid. Together, the intricacy and the option for hollowness provide opportunities for removing any and all material that is not needed for the part’s performance.

Another, similar advantage is the chance to optimize the part’s fit and effectiveness without having to worry about how the resulting shape will be cast or machined. For example, engine makers can modify components to optimize the flow of fuel or air, without having to make any geometric compromises because of the needs of traditional manufacturing.

Plus, additive manufacturing requires no tooling or fixturing, Hockey says. This makes it economical for low volumes. Many high-value production parts are needed in quantities of only 1,000 or so per year.

But he says that the greatest cost savings from additive manufacturing arguably come from reducing or eliminating assembly. A complex subassembly of 10 or more pieces fastened or welded together could be redesigned to be made as a single, solid metal piece through additive manufacturing. While this approach is not inexpensive, neither is the labor and potential for error involved in assembling a critical component. When assembly-related costs can be avoided, additive manufacturing often can deliver dramatic cost reduction while it reduces the overall part count.

Machine Advantages

In certain ways, the design of the Renishaw machine extends the reach of these additive manufacturing benefits. The machine’s build size is one aspect of this. Directed’s Ramirez says the extra clearance in Z already has been important for various parts the company otherwise couldn’t have produced additively.

But another advantage of this machine design relates to the force of the blade that passes across the material with every layer of the build process. On the Renishaw machine, this blade is flexible. That detail might seem like a minor change from the harder blades of the shop’s current machines, but Ramirez says this change expands the range of part designs that can be additively produced. The lower force of the flexible blade has allowed Directed to make parts with thinner walls and more delicate forms than it otherwise might.

It can make more delicate supports, too. Parts produced additively sometimes are made with temporary supports that are removed when the part is complete. On the Renishaw machine, Ramirez can make these supports slender enough to be broken off by hand. On the shop’s other additive metal machines, the parts’ supports have to be removed through a subsequent machining setup.

There is still room for improvement. He says the primary area where he expects to see the new machine get better is in the control interface. Unlike competing machines, this machine’s interface does not make it possible to graphically validate the build cycle on the control screen before the cycle begins. Occasionally, the operator will spot a simple error in programming only by watching through the machine window as the build cycle starts. Stopping the cycle to correct the error and begin again wastes time.

Size and Speed

But temporary shortcomings such as this are acceptable, he says. Renishaw is working to refine the machine, in part by learning from Directed’s feedback. Additive production manufacturing in metal is so new that all of the machines that do this work are still improving rapidly. Certain limitations are common across most or all of the machines that do this work.

According to Fima, the main factor limiting these machines in general is not just build size, but their slow speed within that size. “In metal, the sweet spot for us is producing a part with about the volume of a softball,” he says. New customers are often surprised to learn how long it takes to build such a part. The typical additive manufacturing cycle time for a metal part this size is 18 to 20 hours.

Part of the reason for the customers’ surprise is that additive technology is still often associated with speed. 3D-printing-style technology still carries the label “rapid prototyping”—a term that is doubly questionable. Directed and other companies are proving that this technology is not just about prototyping. Meanwhile, in metal, the technology is not necessarily rapid, either.

In additive manufacturing of plastic parts, the same limitations are not so limiting. Directed’s plastics machines are much larger, as well as much faster. The company expects additive metal machines to improve in both of these respects as well.

For right now, though, the Texas company faces a dilemma. Given the limitations of size and speed, adding one additive metal machine does not add a large amount of production capacity. That’s why the company expects to add several such machines, expanding its machine count dramatically. However, even this will fall short of the level of potential opportunity the company sees for this method of production.

Related Content

2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read More2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreOvercoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read More