VMC Enables Faster, Smoother Cutting

Higher spindle speed and sufficient CNC look-ahead improve efficiency, tool life and surface finish in the manufacture of foam injection molds.

The first part of this video depicts the machining of D2 with a hardness of 62 Rc. The latter part depicts the drilling of 1.75-inch-diameter holes through a piece of 3.5-inch-thick, cold-rolled steel. This is the same hi-lo mast application detailed toward the end of the article.

Jim England had just stepped onto the shop floor one morning when it occurred to him that something wasn’t right. It was just too quiet. After a quick exchange with an employee, the president of Holland, Michigan-based Maslo Fabrication realized his mistake. Gone were the whirring, whining sounds of the warmup cycle on a worn VMC that had long served as the shop’s primary workhorse. In their place was the low hum of a newer model from a different builder that can’t be heard from more than a few feet away. “We needed a runner, and I’d say we got one,” the company president says about the three-axis Doosan DNM 500 II, which Maslo installed in January. “It operates around the clock, and it’s never missed a beat.”

However, the machine offers far more than the reliability that comes with what he calls “solid” construction and the peace of mind that comes with fresh-from-the-factory equipment. Cycle times have dropped by more than half in some cases. Cutting tools last longer, too, and mold surfaces require far less benchwork. “It’s really the meat and potatoes of our operation,” England says about the new machine. “It makes everyone’s day go much smoother.”

A Much-Needed Upgrade

Years ago, England might have said the same thing about the older VMC. “That machine is responsible for getting this shop where it is today,” he says.

In fact, that late-‘90s-era machine is still serving the shop well, he says. The difference is that it’s now limited to relatively simple work, such as 2D operations on the foam injection tooling that constitutes nearly 40 percent of business for this 16,000-square-foot, family-owned operation (the rest consists mostly of contract work and manufacturing vintage industrial furniture). That’s not because the machine isn’t capable of the fluid, 3D contouring that these molds demand—quite the contrary. It’s just not as competitive, he says.

When it purchased that machine nearly two decades ago, Maslo didn’t prioritize spindle speed or CNC look-ahead to the same extent that it does now, England explains. The shop’s foam injection molds, which create parts like automobile armrests or certain types of furniture, are machined entirely from aluminum. Modern methods allow efficient cutting of this material at spindle speeds far higher than the older machine’s 8,000 rpm, he says. The more aggressive the cutting parameters, the greater the need for a CNC that can anticipate and adjust automatically to cutting conditions. Even at lower speeds, look-ahead can help ensure sculpted, contoured mold surfaces are smooth enough to ensure part quality and proper ejection.

With limitations in both areas, Maslo had no choice but to outsource more than 30 percent of its 3D surfacing work, England says. Relying on others not only ate into profit margins, but also limited the four-person shop’s ability to detect problems until far too late in the process (assuming partners’ schedules left room for outsourcing in the first place). Tired of turning away work as demand increased, England and his team purchased the DNM 500 II this past January.

Unlocking Capability

The new machine’s 12,000-rpm spindle is a standard feature. As for look-ahead, he credits Dave Vanealst of distributor Pheonix Machine Tools for helping decide on a CNC option that would meet the shop’s needs without going overboard. In the end, Maslo decided on a Fanuc 0i-MD CNC featuring AI Contour Control II (AiCC-II) with 200-block look-ahead, bell-shaped acceleration/deceleration and Nano Smoothing.

On the floor, the effects of these CNC features are easy to see. “If we programmed the older machine to cut at, say, 400 ipm, it couldn’t handle it,” he explains. “It would hit maybe 80 or 90 ipm, and it would abruptly speed up and slow down in the corners and stutter a lot. You could almost see it ‘thinking’ and struggling to get over a contour, then take off on a straightaway. The Doosan will go all the way up to 400 ipm, and the motion is nice and smooth.”

One reason that motion is so smooth is that the CNC software enables taking full advantage of VoluMill, a toolpath engine incorporated into various CAM packages (in this case, GibbsCAM). This technology keeps the stress on the tool consistent through smooth, flowing tool paths that avoid abrupt changes in direction to minimize stress on the cutter and spindle. Sufficient look-ahead is important because these paths continuously curve, and they enable higher cutting parameters than might otherwise be practical, England says.

Savings from the Spindle

The benefits of a modern CNC paired with technology like Volumill go beyond efficiency, he adds. Smoother motion is easier on cutting tools. Cutting tools also last longer these days because the DNM 500 II’s CAT-40 spindle came standard with a chiller and a Big-Plus interface, both of which help avoid deflection—the chiller by limiting thermal growth in the spindle, and the interface by maximizing rigidity and clamping pressure through dual contact between the spindle face and taper. As a result of these features, tool life has doubled across the board, he says.

The machine’s spindle is also a direct-drive model, which is less prone to vibration than the older machine’s belt-driven spindle, England says. Along with the smoother, faster cutting described above, this helps achieve levels of surface finish right off the machine that are completely unprecedented for Maslo Fabrication. As a result, a mold that might have required three hours of sanding or polishing now takes only about 45 minutes.

Direct-drive also runs quieter, and just as importantly, it adds piece of mind because there are fewer components to monitor and maintain, England says. This adds confidence for lights-out operations. In fact, the Doosan now runs virtually 24/7, a strategy the shop wouldn’t dare attempt with the older machine, he says.

The spindle also features through-coolant capability, which has been particularly beneficial for ramping up metal-removal rates, England says. As an example, he cites a 3.5-inch-thick, mild steel lifting mechanism on a high-lo mast that requires eight 1.75-inch-diameter holes. With the old machine, drilling these holes required removing most material with a 1.25-inch spade drill, followed by helical milling with a 1-inch inserted cutter. This took approximately 20 minutes per hole. In contrast, the Doosan uses only one tool, a 1.75-inch inserted quad drill, to complete each hole in 30 seconds—40 times faster. Overall, the time required to drill all eight holes has been reduced from two hours, 40 minutes to four minutes (see this operation at the end of the video toward the top of the page).

New Business

Such gains haven’t been uncommon since installing the machine. In fact, England says a foam mold that might have required eight to 14 total hours of machining on the older VMC can now be completed in less than four hours on the DNM 500 II.

The additional capacity has been applied for more than just reducing outsourcing of foam mold work. The shop’s newfound efficiency is also attracting brand new customers seeking detail machining work. The VMC has also opened the door to an entirely new opportunity: the design and manufacture of automotive aftermarket suspension components. “With the Doosan, we feel we can now be extremely competitive on cost,” England says.

Related Content

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreRead Next

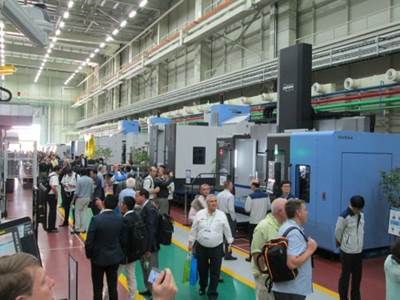

Doosan Intensifies Focus on Milling

At its recent technology fair in South Korea, the machine tool builder revealed innovations that could bring greater balance between milling and turning sales here in the U.S.

Read MoreOvercoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read More