VIDEO: AM Powder Addresses Current Inefficiencies, Sustainability and Skills Gap

Steel supplier discusses high thermal conductivity metal powders that also address the skills gaps via user-friendly materials and promote sustainability via durability and higher cycle counts.

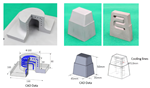

International Mold Steel President Paul Britton discusses the company’s new metal powders with high thermal conductivity to enhance conformal cooling in additive manufacturing. These powders improve cooling efficiency while reducing cracking risks.

To address the industry skills gap, they're creating user-friendly materials and partnering with colleges to provide hands-on experience. Sustainability efforts include recycling practices, electric vehicle use, and producing durable products that reduce the need for frequent replacements.

Related Content

-

Project Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

-

Impact of Bio-Based and Recycled Resins on Molds

Recycled and biodegradable resins require tooling considerations for varying material properties, temperatures and consistent product quality.

-

The Benefits of Alloying Tool Steel

Improve tooling efficiencies, extend mold life and reduce overall tooling costs with a focus on tool steel properties that solve wear, flaking and cracking issues.