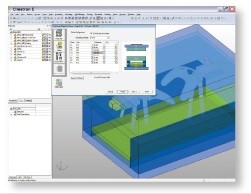

Mold Cooling Design Made Easy

We invite you to sit at your desk on March 12th at 2pm to learn how to quickly create complex water circuits, place cooling components, install baffles at various depths, and analyze circuits and cooling results.

Every shop strives to do its design work better and faster. Extra time spent on each facet of mold design adds up to additional time and cost to the bottom line. Cooling is one specific area in mold design that can now be done quicker and more efficiently than ever before. Register to attend this March 12th, 2pm webinar presented by MoldMaking Technology and Cimatron Technologies to learn how your mold cooling design can be made easy.

You will see quick creation of complex water circuits, speedy placement of cooling components using a rich set of catalogs, fast installation of many baffles at various depths, how to analyze the circuit (for correct water path) and cooling analysis results.

Register Here!

Related Content

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

What Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

Advanced Mold Monitoring for Efficiency

ITW Body and Fuel optimizes mold performance through real-time monitoring and integrated asset management, achieving significant reductions in downtime, scrap rates and maintenance costs.