Is Conformal Cooling Right for You?

Conformal cooling is hot. It’s one of the most popular topics at industry conferences today and yet there are many companies that are still not sure if they are ready to use the technology, according to David Lindemann, who is an applications engineer for 3Dsystems, a Cimatron software business unit. Dave joined MMT recently to present a webinar on the topic.

Conformal cooling is hot. It’s one of the most popular topics at industry conferences today and yet there are many companies that are still not sure if they are ready to use the technology, according to David Lindemann, who is an applications engineer for 3Dsystems, a Cimatron software business unit. Dave joined MMT recently to present a webinar on the topic.

During the webinar, Dave discussed the differences between conformal cooling and traditional cooling processes, how conformal cooling works and what the benefits are to help attendees decide whether it’s right for their molding applications.

Following are a few questions taken directly from the webinar discussion. Check them out and then view the webinar.

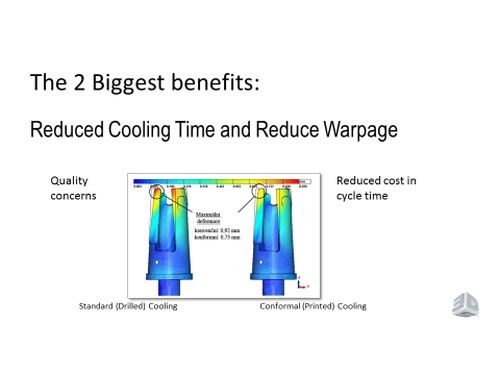

Question #1 – What are the two biggest reasons to consider conformal cooling?

Answer – Reduced cooling time. It’s going to affect the overall cycle time, reducing the piece part price, and who knows, maybe not using conformal cooling means I’m throwing money away. The second biggest reason is reduced warpage. If you can take the heat out uniformly, you’re going to reduce the warpage.

Question #2 – Is following the shape of the part as critical if you have varying wall thicknesses in the part?

Answer – It is still critical because of the need to uniformly take the heat out of the core as much as it is the part. In the list of guidelines (shown in the webinar), maintaining that distance from the wall outside of the core is probably one of the most critical features, even more so than the cross-sections.

Question #3 – Is it your contention that conformal cooling is able to reduce warpage even when the root cause is something like a glass-filled material, off-center gating or some other cause that does not relate to cooling?

Answer – That root cause is still going to be there. That’s part of design. So what we’re talking about is how the cooling will affect the warpage. If you don’t get the heat out of the part uniformly, some areas are going to solidify before others. If there’s an off-set gate causing a problem, that off-set gate will still cause a problem. That’s the basic nature of the material we’re working with.

Question #4 – What materials can you print, can you print different materials in the same core and what finishes can you achieve?

Answer – You can print all kinds of materials including stainless steel, tool steel. It is feasible to print different materials in the same component. With regard to finishing, it’s believed that the printed method gives you 99.9 percent density, so that whatever porosity is there is considered microscopic and they say you can get a B-2 finish by polishing, which, in most cases, is enough. However if you have a case where you need an A-2 finish for a lens quality finish, then it becomes a factor you have to consider. As far as practicality, I have not run across anyone who is attempting to print different materials in the same core, but it sure is intriguing to think about it.

Learn more by viewing this archived webinar here!

If you're looking to really delve deep into this topic, check out some of MoldMaking Technology's coverage of conformal cooling here.

Additionally, we suggest these articles from our sister publication, Additive Manufacturing:

Related Content

Building Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.

Read More2024 Most-Viewed Products

A comprehensive dive into 2024’s most-viewed products, as revealed through MMT's analytics. This review highlights the most popular products, ranging from technologies, services, softwares and more from this past year.

Read More2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreMold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreOvercoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More