How to Overcome Interoperability Hurdles

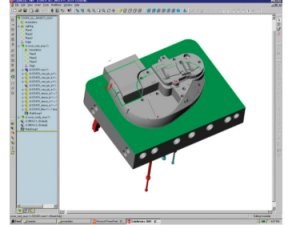

CAD tools help moldmakers import and save information that may be lost in data translation from job to job.

For a moldmaker, every minute spent poring over a paper drawing or filling in the missing surfaces of an IGES or STEP file is a waste of precious turn-around time. Unfortunately, for many moldmakers, this scenario constantly repeats itself. Mold shops are finding their CAM tools unable to take advantage of the feature-rich data coming from major design shops using feature-based solid modeling to design plastic parts. With critical resources committed to high-end machine tools and sophisticated CAM packages, investing in appropriate CAD tools to import and edit design data has not been a high priority.

Every time a shop converts design data from one format to another, it loses an indeterminate amount of part information and design intent. Once the model data reaches the CAM system, the designer rarely hears of any changes made to a part for tooling considerations. The result? The mold shop often misses the nuances of the design and the designer remains blind to the problems that the mold engineer encounters.

The good news is that plastic part designers are rapidly transitioning to feature-based solid modeling tools. Today, modern mold shops are re-thinking their approach to CAD software as solid models have overtaken 2-D and surface models. Many mold shops are incorporating powerful CAD tools at the front end of the mold design process to cut costs, streamline design-to-manufacture and eliminate the interoperability issues that can slow product delivery.

Turning a Problem into an Opportunity

Mold shops have invested heavily in high-performance manufacturing software and equipment with good reason. Having the right CAM package makes the manufacturing process go smoothly. But, while these CAM tools boast powerful toolpath creation and post-processing capabilities, they lack the ability to import and edit the feature-based solid models of the most popular CAD systems.

That mismatch has become a competitive opportunity for leading mold shops that have incorporated solid modeling into their mold design arsenal. Being able to import and start cutting solid models while their competitors are still converting IGES files and patching holes, puts these leading mold shops hours or even days ahead. Starting from a solid model rather than a 2-D paper drawing eliminates the biggest source of errors and puts them at a tremendous advantage over more traditional shops. Even the ability to read native parametric solid models rather than IGES, STEP or Parasolid results in a better understanding of the design intent, leading to significant productivity gains and reducing the risk of production-slowing errors and delays.

Today, nearly all CAM software provides basic modeling tools. Some of these tools have powerful surface modeling capabilities. However, these tools lack feature-based solid modeling that allows a designer to quickly modify a design by changing the feature parameters. When this parametric feature information is lost during data translation, simple CAD tasks such as adding draft angles and changing a fillet radius become much more complex.

Without the feature information, handling engineering change orders (ECOs) becomes much more difficult. A small change to a feature can cause widespread changes to the surfaces of the model, forcing the mold designer to recreate the design. Last-minute ECOs result in a rush to finalize the design without thoroughly checking the change's impact on the rest of the design. For example, discovering a wall thickness problem after the mold has been cut is an expensive proposition.

Breaking the Mold

The basic modeling and translation tools offered by most leading CAM packages are struggling to keep pace with the increasing customer demands placed on mold shops. Some mold shops, particularly in the automotive supply chain, have tackled file interoperability issues by purchasing whatever high-end integrated CAD/CAM software is used by their major customer. But, shops that have ten or twenty key customers face a different problem. Buying and maintaining a seat of every CAD system on the market is a luxury that most mold shops cannot afford.

There is no perfect solution, but the problem is not insurmountable. A quick review of the jobs coming into a mold shop will identify what CAD systems designers used to create the plastic part designs. This will depend on what industry the mold shop serves and in what region of the country they are located. Typically, only two CAD systems make up more than 80 percent of a shop's business, with the remaining 20 percent comprised of a broad mix of CAD packages.

The job information enables a mold shop to select the mainstream CAD system that not only offers the best design tools, but also offers the ability to read native data coming from most of its customers. With such a system in place, file translation and errors give way to dynamic design collaboration and on-time product delivery.

The mold design world is undeniably a 3-D world. Mold shops are at a competitive advantage when they use the same parametric CAD software their customers are using. Using 3-D CAD, these mold shops communicate with customers more quickly and easily, and with more design detail. Moldmakers and mold design shops have solved their interoperability issues by incorporating mainstream 3-D CAD tools and will continue to offer a competitive pricing and time-to-market advantage on a local, national and international scale.

Related Content

The Kentucky Windage Solution in Simulation Reduces Warpage

Using simulation to bias your mold and reduce warpage.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreWhat Is Scientific Maintenance? Part 1

How to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreTooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreRead Next

CAD Interoperability: Its Costs to Mold Design and Mfg

An industry survey reveals some real data on how CAD interoperability is affecting mold shops.

Read MoreOvercoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More