How to Map Mold Water Circuits

Prevent mold damage and maintain consistent part quality by using a mold mapping system that ensures consistent turbulent flow.

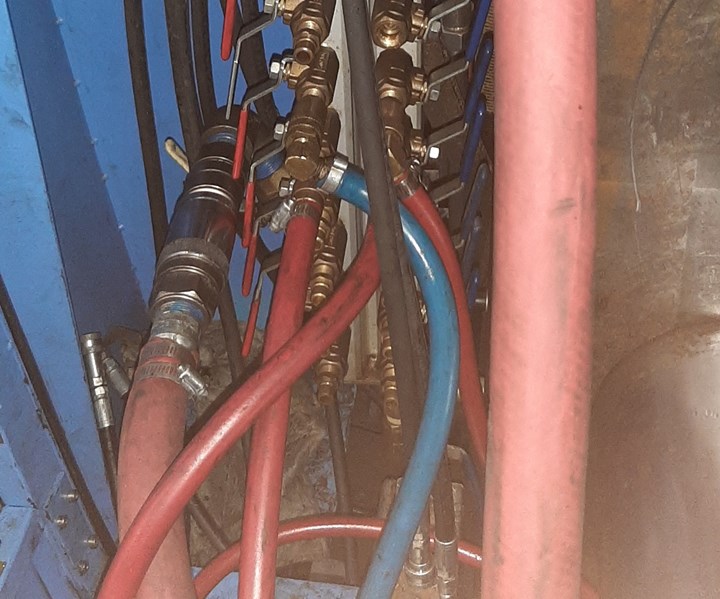

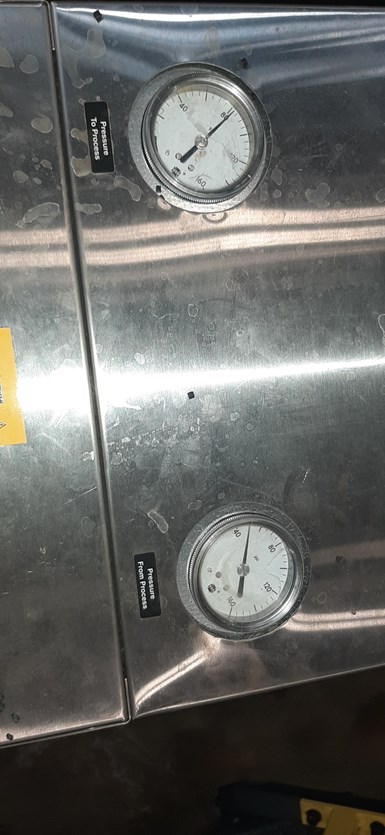

Measuring GPM and pressure of the water going to and from press manifolds is a crucial step towards maintaining proper mold mapping data.

Many factors impact process inconsistency. For example, temperature variations in tooling are detrimental to process control and lead to tool damage, and hot spots cause premature tool wear or mold damage. So how can process control become more consistent? The key is mold watering.

However, even in a shop with treated water, scaling of mold circuits can occur. Treatment processes have improved over the last decade, but they still do not act as a complete fail-safe against the potential of decreased water flow.

A toolroom can troubleshoot changes within a mold watering schematic if the technician measures the appropriate data when a mold is in a good running state. Here are the critical measurables within a mold watering system and guidelines for using this data to identify water issues.

Turbulent Flow

Best described as the rolling and churning action of water, turbulent flow is a primary driver of mold temperature consistency. Increased turbulent flow via improved rolling action expands the water against the circuit wall, which enhances the performance of water circuits and improves temperature consistency across mold surfaces and components. Poor turbulence leads to mold hot spots and temperature fluctuations.

Two primary methods of measuring turbulent flow are gallons/liters per minute and pressure drop for each mold circuit (Note: Save this data for future reference).

Best practice for mold mapping is to record both GPM and pressure drop for each circuit while the mold is in a good running state. This helps to pinpoint changes in water when improper heat conditions are apparent.

Circuit Identification

When mapping mold circuits, label each circuit with a number exclusive to the circuit and a supply or return designation (e.g., 1 IN, 1 OUT, 2 IN, 2 OUT). Flow direction is essential for mold mapping because when water flow reverses, poor turbulence and hot spots occur. For example, baffles require water to flow in a specific direction, and cascades can be receivers of buildup.

GPM

Another key measurable for determining turbulent flow is measuring the amount of water passing through the mold every minute. Higher numbers ensure that adequate water flow and an acceptable turbulent flow level. Minimum turbulent flow is 12 to 14 GPM, and an optimal flow rate is 20 GPM.

Pressure to and from the process can help identify external changes, such as a problem with the water system, or a poorly performing thermolator.

Pressure Drop

Pressure drop is also vital to turbulent flow measurement. A toolroom technician can measure pressure as the water enters the circuit to determine pressure drop, and then compare this number to the water pressure as the water exits the circuit.

If the water exiting is too close in pressure, then flow resistance is low, and turbulence is impeded by passing too easily through the circuit. You can increase pressure drop by using smaller lines on the return side of the mold. Changes in pressure on either side may also indicate a problem with the water system or a thermolator that is not working correctly.

Mapping the circuitry of your mold is crucial in water troubleshooting events. By adequately recording water data, your company improves its ability to pinpoint changes within the mold watering system quickly. Historical data is a the best defense against changes within the process control schematic.

For More Information

Garrett MacKenzie is a process trainer and consultant to the plastic injection industry. His 32-year background includes engineering and management. For process training or mold mapping services, he can be contacted via email: garrett@plastic411.com.

Related Content

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreWhat Is Scientific Maintenance? Part 1

How to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreBreaking Down 3D Scanning in Moldmaking

Identifying 3D scanning requirements and implementing the appropriate technology.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreRead Next

8 Ways to Increase Mold Life

A checklist of molding machine settings and preventative maintenance actions that improve mold longevity.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More