Amerimold is the premier hub for moldmaking and molding education in North America. Every year, the event offers an unequaled slate of education events from the best and brightest in the industry, and with an expanded three-day schedule, more free educational sessions are being offered than ever before.

Take a look at some of our exhibitor’s education sessions below, including three of Amerimold sponsors. Make sure to register for Amerimold 2021 today to add these sessions to your MyShow Planner!

MMT would also like to thank sponsors Edro Engineering, Rey Technologies, Progressive Components, Engel, Beaumont Technologies, Oerlikon HRSflow and Hasco America.

Presented by Amerimold sponsor Beaumont Technologies

Tuesday, Sept. 21st | 2:00 p.m. – 2:30 p.m.

Injection molding simulation is a requirement for every new project launch for many companies.

Speaker: Jennifer Schmidt, Senior Instructor

Presented by Amerimold sponsor Oerlikon HRSflow

Tuesday, Sept. 21st | 1:30 p.m. – 2:00 p.m.

This presentation will review how the processing of a mold can be taken completely from the injection molding machine with the melt delivery system determining the pressure and fill speeds and mold-based events (detected by the sensors) determining the valve gate triggers.

Speaker: Robert Harvey, Sales Director, HRSflow North America

Presented by Amerimold sponsor Hasco America

Tuesday, Sept. 21st | 11:30 a.m. – 12:00 p.m.

This presentation will review the use of DLC coatings on special plate movement items, ejector pins, top and side locks, leader pins to 2-stage ejection and latch locks to keep molds running without grease and minimal maintenance.

Speaker: Brenda Clark, Engineering Manager

Presented by Heidenhain Corp.

Wednesday, Sept. 22nd | 10:00 a.m. – 10:30 a.m.

This presentation will discuss the necessary five-axis machine tool features and functions that will improve the efficiency and accuracy of mold repair, specifically after welding or reworking larger 3D surface finishes.

Speakers: Gisbert Levdon, Director of Business Development Machine Tool

Presented by Mastip

Thursday, Sept. 23rd | 11:00 a.m. – 11:30 a.m.

This presentation will review specific challenges and technology solutions when it comes to molding temperature, gating maintenance, glass fiber breakage, rheology, moldflow analysis and hot runner/mold wear.

Speaker: Tony Brodzeller, Senior Technical Sales Manager

Presented by CGS North America (CAM-Tool)

Wednesday, Sept. 22nd | 10:30 a.m. – 11:00 a.m.

The move to automation is one solution for doing more with less to address the skills gap. The key to this strategy is creating an organizational structure in which a few highly skilled people implement a process that allows computers and machinery to do the work with limited input from employees.

Speakers: Ryan Weekes, President

Presented by Next Chapter Manufacturing

Tuesday, Sept. 21st | 10:30 a.m. – 11:00 a.m.

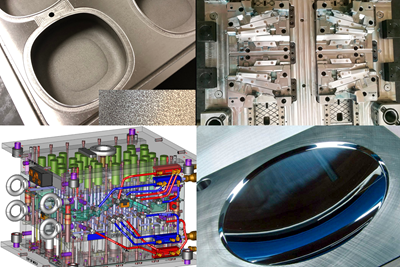

This presentation will explain how 3D printing can vent molds 10-100 times that of traditional venting methods, double the hardness for the toughest high-wear resin applications and keep maintenance costs in line with typical preventative maintenance.

Speakers: Jason Murphy, President and CEO

Presented by Gardner Business Intelligence

Thursday, Sept. 23rd | 12:00 p.m. – 12:30 p.m.

This presentation will look at the sustainability of the current market once government largess pulls back, the effect of continued price inflation on inventory and labor expenses and the impact of companies moving away from Just-In-Time delivery if supply chains continue to be disrupted.

Speakers: Michael Guckes, Chief Economist & Director of Analytics