INCOE Corporation

Global Headquarters

2850 High Meadow Circle

Auburn Hills, MI 48326 US

248-616-0220

incoe.com

About INCOE Corporation

Since 1958 INCOE has focused on providing the plastics industry with innovative hot runner systems, creative solutions, and first-in-class customer service. Our global commitment is to be your Partner, producing value in your process, and ultimately delivering satisfaction where it counts.

IS THIS YOUR COMPANY?

Video Gallery

INCOE Hot Runner Solutions

INCOE - Hot Runner Solutions https://incoe.com/

INCOE - Your Partner

https://incoe.com.

INCOE - Automotive Hot Runner Solutions

INCOE - Automotive Hot Runner Solutions https://incoe.com/

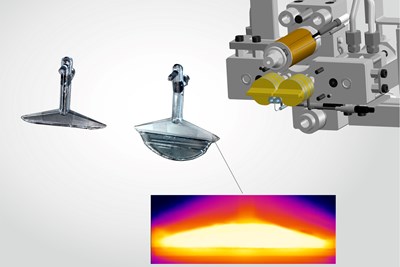

INCOE Corporation - DF Nozzle Series with MultiPower Heaters

The new DF nozzles series with MultiPower heaters. https://incoe.com/

As Seen On Moldmaking Technology

INCOE Corporation Supplies the Following Products

Trade Names Offered by INCOE Corporation

- SoftGate®

- Smart Work®

- Slim-Flo®

- SealFit®

- Opti-Flo®

- Melt Logistics®

- Direct-Flo™ Hot Runner Systems