Providing the Assist

A moldmaker worked as part of a team to design and mold with a new gate-sequenced gas assist application - providing outstanding quality at a lower cost.

What is believed to be the first ever combination of gate sequencing and gas-assisted molding has saved money while providing outstanding product quality in a computer panel application. Using a traditional single-gate approach on this 14-inch by 30-inch part would have required a 1,400 ton press and run the risk of sink marks in any area where the plastic is thicker. Mold filling analysis in the early concept phase revealed that press tonnage could be substantially reduced with gas assist molding methods. Further improvements were achieved by using two valve gates and sequencing injection in order to channel gas to tightly pack the areas where sink marks were a concern. The part is now being produced on a 710-ton press that costs $90 per hour less than the one that was originally planned - and the customer is extremely happy with the blemish-free and warpage-free part.

How It Started

One of the leading computer manufacturers in the world, Hewlett Packard Co. (Roseville, CA), recently decided to convert the enclosure on one of its flagship products from a heavy sheet metal door to plastic. The modular design of the new plastic part allows easy installation and reduces damage sometimes suffered by the metal door. The computer manufacturer selected APW Enclosure Systems (Anaheim, CA) to produce the side panels. APW worked closely with the moldmaker, L.B. Mold (Gardenia, CA) - a provider of quality tooling for structure plastics, injection molding, die cast molds and other types of production tooling - to meet the challenges of this large and complicated part. "From the first time that we began looking at this part we could tell it was going to be a significant challenge," says Gary Nord, plastics operations manager for APW. "First of all, this is a very large part. Filling this part with a conventional single-gate injection system would require a very large press. Our plans were to purchase a new press that would be completely dedicated to this job, so the expenditure would have been great. But even assuming that we went this route, it would have been very difficult to meet the customer's quality requirements. Warpage is always a serious concern on anything this large. In addition, the part has a considerable number of features such as bosses and ribs on one side and I'm pretty sure that we would have had sink mark problems that would have been difficult - perhaps impossible - to resolve."

Featured Content

Use of Gas Assist

In an effort to solve the problem, an independent consultant, Mike Caropreso of Chester, MA, was asked to review the results of the analysis and develop a method for economically producing the part while meeting the customer's high quality standards. "From the beginning, I felt this would be an ideal application for gas assist molding," Caropreso notes. "By eliminating the need for the press to provide packing pressure, it was obvious that gas assist would make it possible to produce the job on a considerably less expensive machine. In addition, by more efficiently packing the part, gas assist can often eliminate warpage and sink marks."

In a typical gas assist molding application, the object is to fill components with less than 100 percent material, then inject gas to pack the mold and create a tube flowing towards the lower pressure areas. Gas can penetrate the part either through the nozzle or through gas pins placed in selected areas of the mold. Gas will travel through the channels, displacing plastic from the thicker sections to do the packing. This is to avoid sinking due to shrinking of the plastic as it cools. It's important to note that gas will tend to flow into areas that have higher temperature and lower pressure. The designer needs to make sure that gas is directed towards sections of the part where sink marks need to be avoided. Specialized gas assist molding analysis tools can accurately predict gas penetration through the filling and packing cycle.

Need for Valve Gate Sequencing

Caropreso calculated that the use of gas assist would reduce the required press tonnage to 710 tons, enough to substantially reduce the cost of the press. On the other hand, Caropreso wasn't certain that gas assist on its own would resolve the important quality concerns revealed by the mold filling analysis. In particular, he wasn't sure how it would be possible to ensure that gas could be directed into the areas with complex features that were prone to sink marks. Then he had the idea of combining gas assist with valve gate sequencing, a technology that is normally used to reduce warpage in larger parts by filling parts one section at a time in order to reduce residual stresses.

While that particular advantage was beneficial in this application, Caropreso's primary reason for using valve gate sequencing was to precisely control the flow of material through the mold so that he could ensure that enough gas pressure would be available to pack material tightly into areas where sink marks were a concern. His concept was to closely control the filling of the mold by injecting material first into one gate then, just as the material reached the second gate, opening up the second gate. "Sequencing the filling process made it possible to place the short shot exactly where I wanted it to be," Caropreso says. "I also changed the part design to add channels - pathways with a larger cross-section intended to keep material molten long enough to provide a tunnel for the gas to flow through. They act like an expressway moving the gas directly toward the critical areas of the part." General Electric performed mold-filling analysis on the part to confirm the viability of this concept.

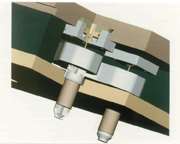

Selecting the Valve Gate System

APW and L.B. Mold recognized that the valve gate system would play a critical role in the injection molding process. It must be capable of delivering carefully metered amounts of molten material at the precise instant when they are required. They selected the Incoe valve gate system and gate sequence control system from Incoe Corporation (Troy, MI) because it had excellent experience with this product in previous applications. The controller provides precise control of the injection process. The system is designed to allow for two open and close sequences per valve gate. It can be activated by linear position or time. Programming takes place through a graphical interface that runs on the Windows operating system.

Another important part of the application was delivering the material into the key with a minimum of stress and sheer. To accomplish that goal, APW and L.B. Mold selected Incoe's Clear-Flo valve gate system that removes the pin from the melt channel during mold fill. After mold fill, or on command, the pin closes off the material flow at the gate well. The pin only contacts the melt just prior to close, which helps eliminate flow lines. The new design also increases the flow channel, which minimizes flow-induced material stress. It allows material to maintain a consistent velocity from the manifold entrance to the gate area. The system also features a new valve gate actuator, which operates with either hydraulic or pneumatic pressure.

Meeting Quality Requirements

APW purchased a 710-ton press which mold filling analysis showed would be sufficient to produce the part using a two-valve gate injection with gas assist. The injection molding process worked beautifully almost from the very first shot. "This is one of the toughest jobs that this customer has ever given us," Nord says. "Everyone was expecting a fairly lengthy trial and error process in order to get the part right. Instead, everything worked almost perfectly. The smaller press was able to handle the job without any problem. Dimensional accuracy was excellent from the very beginning. Best of all, the packing provided by the gas assist totally eliminated sink marks. Only a few minor adjustments to the process were required to meet the customer's requirements. And we have been able to maintain this high level of quality with minimal adjustments, so there has been virtually no downtime on this operation."

"This was one of those projects where everyone performed beyond expectations," Nord notes. "But I think the success of the project is particularly due to combining gas assist with valve gate sequencing and the ability of the Incoe gate sequence controller to deliver precise amounts of material at the exact moment they are needed. That's how we eliminated warpage and sink marks from this part." APW, L.B. Mold and their customer aren't the only ones that recognize the difficulty and level of accomplishment that was achieved on this part. It recently won the 1999 Best Single Part Award and Computer & Business Equipment Award in the Society of Plastic Industry, Inc. Structural Plastics Division's national competition in Boston.

RELATED CONTENT

-

A Different Approach to Mold Venting

Alternative venting valves can help overcome standard mold venting limitations and improve mold performance.

-

How to Choose the Right Tool Coating for Your Machining Application

Selection criteria and common coating attributes for PVD, CVD and other common coatings.

-

7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.