Photo Credit, clockwise, from top left: MC Machinery, Heidenhain, Fastems and Hardinge.

In this day and age, it’s imperative for mold shops to adopt and implement technologies that will improve efficiencies across the board to meet — and exceed — quality requirements and customer expectations, and maintain a competitive edge in the industry. The sheer amount of new technology, however, can be daunting to many.

Every month, MMT releases a technology roundup highlighting different products, processes and services. This month’s roundup has a specific focus on EDM, automation and machining, providing you with a rundown on how these products and services can be useful to you and your company, whether it’s automating work schedules, high-precision surface grinders, jig grinders or milling machines, EDMs that meet mold production demands and more.

Curious to know what the most viewed products of the year were? We’ve got you covered there, too. Check out the Most-Viewed Products of 2022.

To check out tech from months prior, please browse the “New Tech” section on the MoldMaking Technology website. For more information on a product featured below, click the title link for the respective product.

Automation

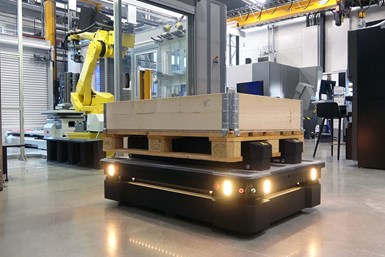

Photo Credit: Fastems LLC

Within the past few years the number of Fastems’ CNC automation solutions utilizing automated guided vehicles (AGV) or autonomous mobile robots (AMR) has multiplied, and the demand keeps rising, the company reports. Typical AGV applications include material intralogistics, delivering tools to machines and moving machining pallets between production process phases. The common goal of all the AGV projects is timely, safe and economical transfers of production items and Fastems is actively developing ways to use these technologies efficiently with CNC automation.

Photo Credit: Fastheat by Spark Industries

Fast Heat by Spark Industries is highlighting the ReadyCobot, a collaborative robot solution enabling tool shops and molders to overcome labor shortages, improve quality and lead time, improve flexibility and ultimately reduce costs. Applications that can be performed by the ReadyCobot include assembly; bin picking; palletizing; inspection; machine tending; loading and unloading; drilling, milling, sanding or screw driving; and packaging.

The LoadMate Plus Machine Tending Robotic Cell from Absolute Machine Tools partner Mitsubishi Electric Automation streamlines part loading,

Photo Credit: Absolute Machine Tools

unloading and palletizing in low-to-high volume applications. It features portability, easy setup and programming, high performance and a safety-first design that make it appropriate for both job shops and larger scale production environments.

Mitsubishi and Absolute jointly designed the plug-and-play cell. It consists of a Mitsubishi industrial robot, a wheeled stainless steel base, a clear polycarbonate cell enclosure featuring a safety door with an interlock switch and a side table extension.

Photo Credit: Shop Floor Automations

The Scytec DataXchange machine monitoring solution, available through North American manufacturing integrator Shop Floor Automations, is one such smart factory technology. This solution helps manufacturers gain automated visibility across all collaborative and industrial robots, as well as other CNC, fabrication, assembly and legacy or manual equipment, according to the company.

By pulling data from all devices within a manufacturing cell and synthesizing it with a company’s enterprise resource planning (ERP) and other core systems, moldmakers can identify and take informed action on the following intelligence, and much more

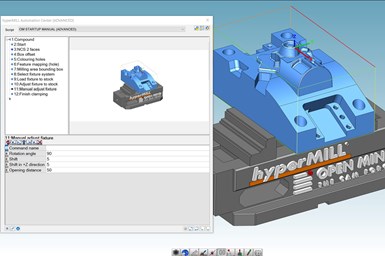

Photo Credit: Open Mind Technologies USA

Parts with similar geometries such as component families and variants, recurring shape elements, features such as holes or pockets, and repetitive processes provide an ideal opportunity to implement automated CAM programming. Open Mind Technologies’ hyperMILL CAD/CAM software now offers new automation technology and a comprehensive Automation Center, all which help to reduce programming times, standardize processes, eliminate human error and improve overall throughput in the moldmaking industry.

hyperMILL CAM programmers are provided with a toolbox full of closely interlinked technologies to automate individual or complex processes. According to the company, this makes it easy to define and adhere to manufacturing standards.

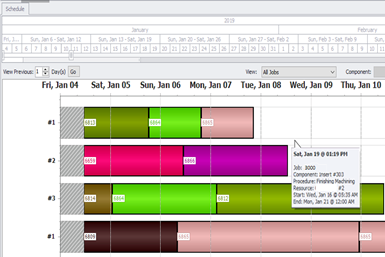

Photo Credit: R.E.R. Software

R.E.R. Software’s AutoPlan product was built with automation at the core. Moldmaking is a very competitive market, and automation cells are becoming the reality for forward-thinking shops. One of the largest challenges facing these shops is having available work prepared and ready for the automation cell. This is where R.E.R.’s InFocus suite and more specifically, AutoPlan, shines, according to the company.

AutoPlan is said to remove all of the struggles that are associated with manual scheduling. Employees no longer have to walk the shop floor to see what is ready, or if the material is received and prepared. A living schedule, AutoPlan is continuously shifting and reacting to real-world situations and complexities in a manufacturing facility.

Designed to decrease the apprehension and intimidation some manufacturers might face during their initial foray into robotic automation, the new KUKA Robot Guide makes the process fast and easy to apply the right automation to specific application needs. In only three steps, users are presented with KUKA robot options based on industry, application and environment for an optimal automation match.

Within the guide, users are able to choose between a variety of industries, including automotive, food and beverage, medical, plastics, electronics and metal, then drill down to almost any application environment.

Machining

Hardinge highlights the Hauser 2,000, a newly debuted jig grinder for mold and die that combines highly accurate grinding with hard milling features. It enables a high finish (0.01 Ra), an ideal feature for some of its customers who use it for injection molds.

The six-axis machine is a dual-frame design, increasing the rigidity of the grinder, and therefore ensuring high precision; its electrical connection, heat exchangers and other systems are also made separate from the main cell to reduce vibrations and ensure optimum quality. Moreover, no transverse forces are created — the prerequisite for ultra-high geometric precision machining, according to the company.

Photo Credit: Chevalier Machinery

Intelligent, dynamic and affordable are three words that are said to describe the driving forces behind Chevalier Machinery’s newly design Smart-IV Series of CNC surface grinders. They’re also the benchmarks required by the medical, energy, semiconductor, aerospace, mold and die, and processing industries to meet current and future market demands.

With six machine sizes available, this series is capable of producing complicated shapes along with finer finishes, resulting in highly accurate workpieces, according to the company.

Roeders says the RXU 2000 is suited for 3D milling as well as for jig grinding, vertical grinding or profile grinding. This combination of operations in one setup on the same machine is particularly ideal for many jobs in machine and moldmaking including large mold plates (such as for progressive dies); large, flat injection molds with fine contours (for seals), which have to be machined with relatively small tools; machine components (like guide rails); and large, high-precision workpieces.

Photo Credit: DN Solutions

DN Solutions introduces the new Puma DNT 2100 and 2600. The DNT Series will replace the popular Puma GT 2100 and 2600 models, with upgrades in enhanced rigidity, usability and accuracy, and a focus on convenient operation and easy maintenance. This DNT Series comes in a two-axis and a milling version, with a 25 hp (18.6 kW) or 35 hp (26.1 kW) motor that turn the machine’s spindle at speeds ranging from 3,500 to 4,500 r/min.

Like the GT Series, box guideways are applied to all axes on the DNT Series to prevent vibration and ensure dynamic rigidity during heavy-duty cutting.

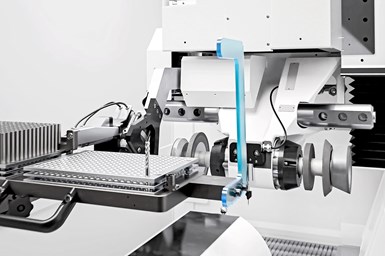

Walter’s latest addition to its comprehensive machine lineup is the compact Helitronic G 200 tool grinding machine, a key solution for affordable, versatile in-house regrinding operations in a mold shop. In a floor space of less than 24.8 square feet, the Helitronic G 200 offers grinding and re-sharpening of rotationally symmetrical cutting tools ranging from 1 to 125 mm (0.039" to 4.92") in diameter with a grinding wheel up to 150mm (5.91"), ideal for moldmakers, who typically utilize a high volume and mix of cutting tools.

DMG MORI’s latest hybrid 3D printer offers increased application possibilities by providing easier process integration and component potential for mold and die professionals. The Lasertec 3000 DED hybrid combines laser deposition welding by means of a powder nozzle and five-axis simultaneous machining — including turn and mill technology — in one workspace setup.

Thanks to the space-saving compactMaster spindle, the machine offers sufficient room for a wide range of components, so that mold builders, semiconductor, medical and aerospace sectors can use the hybrid machine for a variety of applications.

Photo Credit: Methods Machine Tools Inc.

Methods Machine Tools is now distributing Nakamura-Tome’s SC-100X2 twin-turret multitasking machine, which utilizes two tools on either side of the upper turret for superimposed machining. Methods spokespeople say this makes it well-suited for Swiss-style parts greater than 25 mm in diameter.

Superimposed machining lets shops take on complex contracts and complete them faster than other mainstream machining methods. Operators can also use the upper and lower turret simultaneously, giving the SC-100X2 the flexibility of a true twin spindle machine.

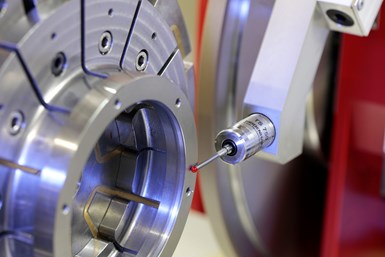

Heidenhain’s TS 750 high-precision touch probe is now available for in-process workpiece measurement in grinding machines and lathes. The highly durable probe offers the ability to state the reproducibility of its jobs at increased probing speeds with low probing force, the latter of which Heidenhain says is an important benefit when working with soft or delicate workpieces. Ultimately, when dialing into mold applications, the machine is a solution for high-accuracy parts grinding.

Photo Credit: Okamoto Corp.

The PSG-1224CANC from Okamoto Corp. is a full-function, two-axis, simultaneous CNC form grinder ideal for surface, slot, step, form and contour grinding. It’s well suited for mold base preparation and grinding of formed inserts/profiles on mold inserts, featuring advanced column design and construction, consistent accuracy and ease of use.

Some of the many standard accessories include grinding wheel with adapter, spindle inverter, three-point table mounted dresser, wheel guard with coolant nozzle, table splash guard and more. A wide selection of optional accessories are available.

Photo Credit: United Grinding

United Grinding has developed the Studer S36 to meet the demand for suitable, productive grinding of external grinding of chuck and shaft components. This concept is capable of extending into mold and die and aerospace industries, but also the production of parts for the hydraulic and automotive industries. The S36 is positioned between the compact S11 for small workpieces and the S22 for medium-sized workpieces. New functionalities for changing requirements are said to supplement proven concepts.

Mazak North America says its Integrex i-100HS multitasking machine offers a small footprint and simultaneous five-axis capabilities along with maximum versatility, high precision and throughput for complex part applications. The system is also said to ensure the shortest possible machining cycle times, especially in fine-increment programs for free-form, mold/die machining.

The German-made Endura 700Linear series from Fooke, a specialist for large and very large gantry milling machines, has been sold and proven in numerous applications, the result of its power and reliability. Machines in this series have been continuously optimized since 2004, characterized by an optimal ratio of structural rigidity and motion control, combining for high productivity and improved machining quality. The series also meets customer expectations in terms of a large machining area, a small footprint and foundationless installation.

Photo Credit: Grob Systems

Grob Systems developed its volumetric compensation cycle, Grob swivel axis calibration (GSC), for the company’s five-axis universal machines more than seven years ago. Where the industry standard is compensating the machines using four data points, Grob’s GSC feature enables it to compensate with more than 50 data points. This has enabled the company to more accurately map out any errors that exist, which has reportedly led to large advancements in volumetric accuracy.

Photo Credit: Air Turbine Tools Inc.

Successful five-axis milling requires tools to reach into angles and pockets, and most machines cannot perform detail work fast enough or efficiently. The extended barrel 625HSK-L100 from Air Turbine Spindles, however, is reported to solve this issue.

Reaching 100 mm into pockets and angles, the 625L100HSK63 mills at 50,000 rpm in high-speed steel (HSS), proving 6-10 times faster cycle times in milling, marking and finishing operations. This enables mold builders to make any CNC machine a high-speed machine, Air Turbine notes, while dramatically accelerating mold machining capabilities.

EDM

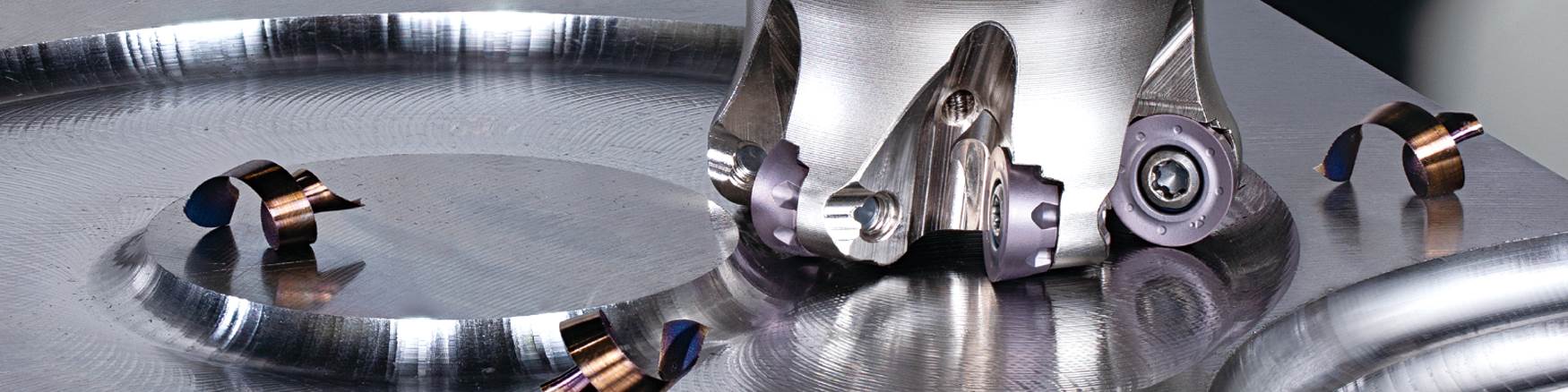

Photo Credit: MC Machinery Systems Inc.

The Gantry Eagle 1400 sinker EDM, according to MC Machinery Systems, is a true workhorse for all large mold shops, offering enhanced electrode wear — requiring less maintenance and costly downtime — and improved cycle times for high return on investment (ROI). It combines the latest in technological innovation with a human-centric design for utility across a number of projects, materials, industries and more.

Photo Credit: Xact Wire EDM

Xact Wire EDM manufactures components for both prototype and production molds used in a variety of applications, from overmolds and insert molds to micro injection molding for surgical devices. The company’s contract wire EDM services can also be used for cavity and component rebuilding or repairs.

Wire EDM is ideal for working with the hardened and pre-hardened metals frequently used in moldmaking such as P-20, S-7, H-13 and 420 stainless steel. Xact says it can perform EDM cutting directly on the mold or by using wire EDM blanks to manufacture specific mold components or inserts.

Combining the power of discharge control technology with rigid linear motor control and the latest artificial intelligence (AI), the Sodick Inc. ALG die-sinker EDM series provides stable machining for every product, every time, the company reports. Improved performance and faster machining speeds are additional features inherent to the product series.

With an ever-growing demand for automation in job shops, Sodick says its ALG sinker series was designed to fit a wide range of automation needs.

Photo Credit: YCM Alliance

YCM Technology (USA) Inc. announces the latest in its lineup of application-based machining solutions, the exeron 316 sinker EDM machine. The new release complements an array of comprehensive machining solutions developed for mold and die and general parts machining associated with medical equipment, automotive, aerospace, defense and energy applications.

Photo Credit: Belmont Equipment and Technologies

Belmont Equipment & Technologies’ exclusive Maxicut Series ZNC EDM sinker machines have been a proven provider for the industry, including moldmaking, aerospace and production applications, the company reports.

The MX-236CW ZNC EDM Sinker features Windows control and a compact machine design. The EDM generator attached to the machine body, and an oil reservoir in the base of the machine, reduces floor space and eliminate cables on the floor. The system uses Belmont’s On-Board Technology which provides EDM settings that are selected through a user-friendly technology database.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)