Hardinge

1235 Westlakes Dr.

Ste. 410

Berwyn, PA 19312 US

800-843-8801

hardinge.com

IS THIS YOUR COMPANY?

Video Gallery

The USACH BoulePro is setting the standard for SiC grinding

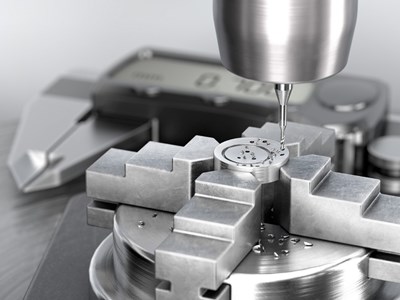

Hardinge Forkardt FlexC Adapter

The Hardinge Forkardt FlexC Adapters are ideal for shops looking for ultimate flexibility! Now in one setup a customer can use ...

USACH BoulePro 200 Overview

Currently the only machine of its kind, the BoulePro 200 allows for a much faster and cost-effective boule-to-puck conversion to ...

Americas Machine Tool Company–July 4th Flag part run

Hardinge is showcasing our talents and for fostering a community that celebrates innovation and collaboration! Right here in our ...