October 2015 Issue

October 2015

Features

Featured articles from the October 2015 issue of MoldMaking Technology

From Camera Assembly to Full-Service Medical Manufacturing

Having already made a significant mark on the mold manufacturing sector, Canon Virginia is setting its sights even higher.

Read More

Maximize Hard Milling with Balanced Machining Process Factors

Successful application of high-speed milling of hardened steels requires an understanding of the many factors that influence the entire machining process.

Read More

Designing a Better Heat Exchanger - Part 3

In part three of our three-part sub-series on mold water cooling systems, we review the impact a water system can have on mold performance and part quality.

Read More

"Rule of Thumb" vs. Engineered Lock Selection

A guide that applies engineering principles is designed to help engineers select properly sized alignment components.

Read More

Taper Angles and Wire EDM

Software can help compensate for excessive erosion during taper cutting with wire EDM.

Read More

The Economics of Metric

Why pay extra for inches when world economics is moving the U.S. into the metric age. Will this motivate the U.S. to convert in the next two years?

Read More

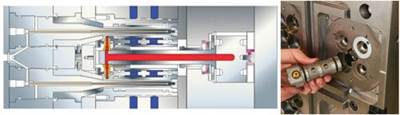

Direct Side Gating

Mold builders and molders should carefully consider hot runner selection, as it dramatically impacts an injection molding system’s speed, quality and uptime.

Read More

Tax Benefits from Manufacturing in the U.S.

The IRS has issued recent guidance related to the domestic production activities deduction (DPAD) that may be particularly favorable to moldmakers.

Read More

Design Out the Effects of Gravity with Mold Orientation

Gravity will have very little influence over the majority of injection-molded plastic parts, but under the right conditions, it can certainly alter the filling of a mold and the resultant part quality.

Read More