The Economics of Metric

Why pay extra for inches when world economics is moving the U.S. into the metric age. Will this motivate the U.S. to convert in the next two years?

Is it time for U.S. moldmakers to take a second look at mold bases and components based on metric measurements because they may be able to save money and maintain quality?

The global economy has made the metric system its standard. This drives mold component suppliers around the world to primarily use metric sizes. As the number of metric users goes up, the number of users of the imperial system (inches) goes down. When the size of the metric market increases, prices for metric products reduce, thus prices for imperial-based products go up. This change will cause U.S. moldmakers working in inches to pay more for their mold components. And so, the campaign to move metric forward within mold manufacturing continues.

My campaign began when a mold component supplier I was working for discontinued its inch-based components, but today, after three published articles in MoldMaking Technology on the subject, I am still compelled to continue explaining to moldmakers the importance and benefits of moving in the metric direction. Today’s convincing argument for metric may be the aforementioned efficiencies in production costs.

To help build my case, I turned to Bill Wood of Mountaintop Economics in Greenfield, Massachusetts, for some education in plastics economics. He says, “The pace of change in this industry is accelerating because it has to change quickly to compete, but until recently it has been slow to adopt certain things, such as metric. However, I do not yet have enough information or data to make a forecast or even identify metric as a trend.”

So, what data is necessary to evaluate this change to metric in the U.S.? How about some input from steel suppliers to learn if they are experiencing an increase in metric plate thickness requests, particularly 27-mm plate?

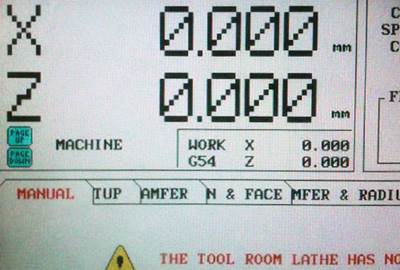

When I was first introduced to metric mold bases, I compared standard metric thickness to standard inch thickness. I noticed that most sizes worked out, meaning you could take a standard inch-sized plate and machine it down to the standard metric thickness without a lot of material waste. However, 27-mm thickness (1.063 inch) was the one size that did not fit very well, because the standard imperial size is 1.375 inch, which results in a lot of wasted material when machined down to 27 mm.

I asked several steel suppliers, “Over the last three to five years, have you seen an increase in the sale of metric plates, specifically 27 mm (1.063 inches) for mold plates in 4140, 420PH or P20 material? If so, can you quantify the increase per year?”

Paul Jackson, a sales representative for Edro Engineering and Specialty Steels, Inc. in California, says he has seen an increase in metric orders. Rolling plates to special thickness is no big deal to this steel supplier, because it has a mill in Pennsylvania that can roll virtually any material to the thickness required. This offers the company a big advantage on price, as it is not wasting excess material. He also explains that the company prefers European-style mold bases that feature the same bore size in every plate and no offset hole, because they are much easier to machine, and it is less expensive to machine one hole size in every plate.

At Pennsylvania-based Mold Base Industries Inc., which primarily manufactures custom mold bases, President Sam Shiffler says his company actually has been seeing fewer metric requests this year compared to last year, but it is busy with custom inch bases. He also prefers the European-style and believes it is easier to manufacture.

Wayne Sikorcin, owner of Craftsman Tool & Mold Co. outside of Chicago, is fielding increased requests for metric mold bases as his customer base grows. He says all of the mold bases built for the company’s international customers are metric, and he also believes that the U.S. market will become primarily metric within two years.

It is still not clear if this change from imperial to metric is actually underway. How could one mold base supplier see a decrease in metric orders while two others are seeing big increases? This may be because the suppliers that are increasing their metric orders have established an efficient way to handle those metric orders and are therefore more competitive. They also may be pursuing more international customers, which are mostly all metric-based.

Schmolz+Bickenbach USA, Inc.’s sales director, John Stocker, has not seen any noticeable increase in metric inquiries or in requests for specific sizes of plates. He says that when a tool print originates from Japan or Germany, metric is often referenced, but most toolmakers will convert it to imperial when they send the RFQ.

Jereme Bohling, product manager for plastics at Bohler-Uddeholm Corporation, reports that, although its own data did not indicate an increase in metric requests, the company is cutting and machining to size on every order. Customers are not asking for 27-mm plate. They specifiy the finish size they need, and Bohler-Uddeholm supplies material that will finish to this size.

The responses from these major steel suppliers then begs another question: Are they anticipating a transition to metric measurement by the U.S.? Orders for non-U.S.-standard plate thicknesses seem to be treated as orders for custom thicknesses, because, at the moment, that is perceived to be the most efficient way to handle them. If that is the case, is now the time to reach out to their European colleagues for a way to handle metric requests as metric instead of converting them to imperial with U.S. standards and tolerances?

It’s understandable that there is not more evidence of the metric change being fully underway today. If there were, we would probably see the change within the next year. I forecast it happening within two years. The fact that metric bases shipped from Europe are competitively priced with U.S. inch bases may be an indication that the change is underway.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreForces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreRead Next

Think Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

Read MoreThink Metric: It’s All in the Numbers, Part 2

Feedback from the field on making the metric conversion in your shop after realizing it just makes sense.

Read MoreThink Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)