November 2008 Issue

November 2008

Features

Featured articles from the November 2008 issue of MoldMaking Technology

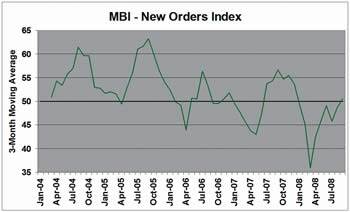

Mold Industry Continues to Slip

46.7 Total Mold Business Index for September 2008 The total Mold Business Index is a weighted average of the sub-indices for new orders, production, employees, backlog, exports and supplier deliveries.

Read More

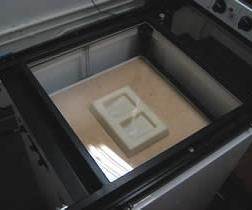

Printing Vacuum Forming Tooling with FDM

Combining the advantages of 3-D CAD and FDM technology, vacuum forming can be completed quickly, efficiently and cost effectively

Read More

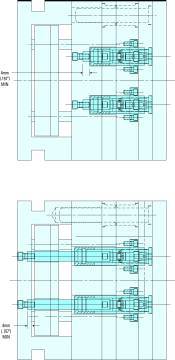

Plate Positioning Perfected

Consider a positive precision plate device to overcome the risks and uncertainties inherent with springs and spring limiters.

Read MoreTime to Engage

This AMBA event brought together the highest number of mold manufacturing participants the group has seen.

Read More

Material Matters

Hardness, machinability and strength are the bottom line as materials manufacturers and suppliers continue to reduce moldmakers’ leadtimes without sacrificing quality or cost.

Read More

Nanotechnology Benefits to the Mold

Nano-formulated mold coatings can address the part fill and release challenges that come with highly complicated design requirements, expedited manufacturing expectations and high raw material prices for molds and resins.

Read More

Part Two of a Two-Part Series EDM’s Effect on Surface Integrity

To improve the potential for success in quality mold production, moldmakers need to understand some specific characteristics of the electrode material as well as certain facets of the EDM process that affect surface finish and integrity.

Read More

Low-Volume Layered Manufacturing: Parts without Limits

An alternative design and manufacturing method that uses a layer-by-layer process, virtually eliminating part design constraints that exist with traditional manufacturing processes, such as CNC machining and injection molding.

Read MoreHow Good Is Your Process?

Everyone has a process, how much you can derive from it depends on how robust your process is.

Read More

ABCO Tool & Die, Inc.: Eyes on the Prize

Continuing to focus on its specialty of producing optical molds, this mold-maker’s vision of becoming a resource to its customers is realized by equipment and technology upgrades.

Read More

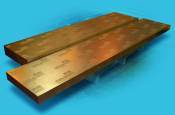

A Low-Tech Solution for Cutting Moldmaking Costs

Machine-ready blanks have been available for decades, yet mold manufacturers have been slow to adopt them, even though they can save as much as 30 percent off overall mold and mold component costs and free up machine time for creating more in-house capacity.

Read More

Automation Innovations

The use of automation continues to rise as mold manufacturers respond to industry demand of constantly shrinking leadtimes. Manufacturers and suppliers have taken action with better, faster equipment and processes.

Read More

Is It Still Time to Reach for a Die Profiler?

Pointers for bringing a polished surface to a high mirror finish. You have finished machining your mold core and cavity and removed them from your CNC machine. The mold components are machined in tough H-13 steel and contain several deep grooves and slots that must be properly polished to allow the molded part to eject. What is the best method for bringing the polished surface to a high mirror finish?

Read More

Specialization and Automation Give Matrix an Edge on Competitors

Mold shop’s focus on high-tech capabilities and full-service operation earns it a niche in precision tools.

Read More

Market Looks Razor Sharp

Great strides continue to be made in the cutting tool/toolholder market that result in reduced benchtime and additional handwork, as well as heavier depths-of-cut—adding up to increased productivity and higher accuracy.

Read More

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)