Viewer Software Assesses Moldability of Parts in 16 CAD File Formats

Kubotek3D’s K-Display View is a multi-CAD visualization software offering mold-specific features such as colored shading based on draft angle and 3D bounding envelope size and measurements.

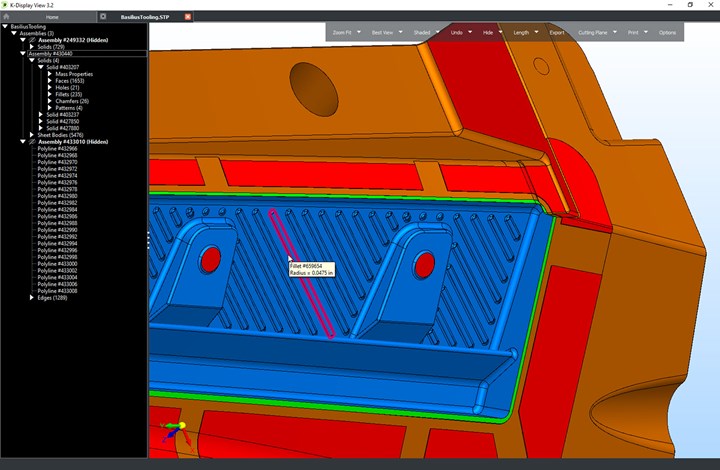

This image shows a mold built by Basilius in Toledo for an automotive part (STEP file exported from KeyCreator). The cursor ToolTip is displaying the radius of a feature which a machinist would need to know when selecting tooling for this job. Photo Credit: Kubotek3D

A simple, intuitive interface enables quoting, manufacturing, sales, support and service departments to all easily view and interrogate 3D CAD files. Initially released in 2018, Kubotek3D’s K-Display View offers mold-specific features, including colored shading based on draft angle, 3D bounding envelope size and measurements of distances, volume, area and thickness.

According to the company, the product is a local install, read-only program, eliminating the need to save a changed version of the file or to upload sensitive/customer data online. The program has options to read 3D files from all major mechanical CAD programs and standard formats. Advance support includes five native drawing formats, semantic 3D GD&T (PMI) and discovery of duplicate bodies.

Powered by Kubotek’s next-generation Kosmos technology, K-Display employs full multi-threaded processing which is guaranteed to bring a new level of speed when opening larger files, says Kubotek; it is supported on Windows, Mac and Linux. No additional CAD software licenses are needed. Network floating versions and lease or permanent license as available.

Related Content

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

Plastic Injection Molding Starts with the Pellet

This summer, let’s get back to the basics. For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. This week: what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.