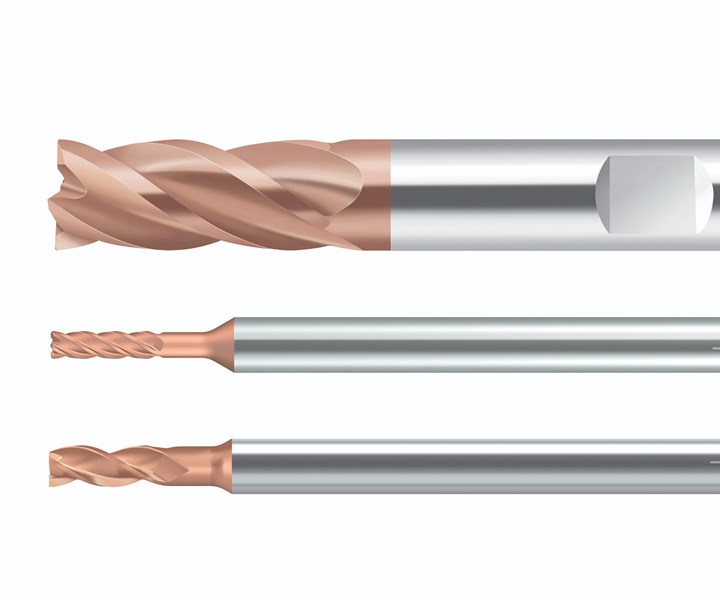

Solid Carbide Milling Cutters Feature Corner Radius

Walter introduces the MC232 Perform line of solid carbide milling cutters. These milling cutters feature a corner radius and reduced neck.

Walter introduces the MC232 Perform line of solid carbide milling cutters. These milling cutters feature a corner radius and reduced neck. Solid carbide milling cutters with corner radii enable improved approaches to individual component geometries. It also improves the tool life of the milling cutter, as the edge stability is increased. The reduced neck in turn makes the milling cutter more flexible, as it can be used with an even wider variety of cutting depths. Diameter sizes range from 1/8 to ¾-inch and 2-20 mm metric, which can be used for typical milling applications and are suitable for a variety of materials.

Related Content

-

How to Optimize Mold Finishing

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

-

Modular Tooling Systems Enable Versatility in Hole-Drilling Operations

The versatility of replaceable cutting edges offers users the ability to adapt to varied operations.

-

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.