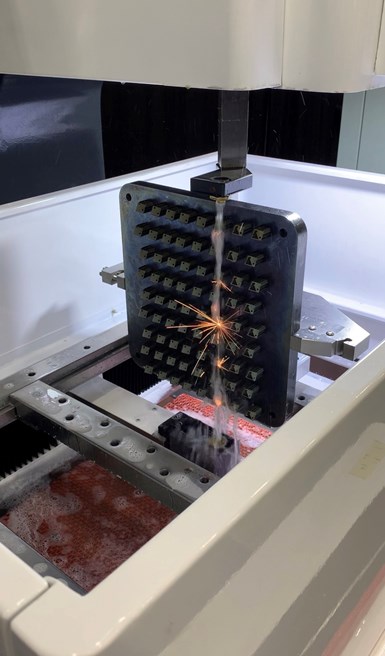

EDM Machine Enables Rapid Metal Parts Removal

According to EDM Network Inc., the Fast Wire EDM is capable of cutting speeds that are two to three times faster than traditional wire EDMs.

EDM Network Inc.’s Fast Wire EDM is designed to rapidly remove 3D-printed metal parts from the build plate by using a small 0.007" diameter molybdenum wire to cut a 0.008" wide kerf. This narrow kerf enables the EDM to cut about 0.010" away from the build plate, which reduces the cost of the additional support material needed by traditional saws.

According to EDM Network, its Fast Wire EDMs are different from traditional brass wire EDMs because they are not flush dependent and do not need auxiliary flush lines or submerged cutting. In the interrupted cuts on a tall build plate, the Fast Wire EDMs will not break the wire because the molybdenum wire has very high tensile strength, and the water additive that is used causes the water to adhere to the fast moving wire, enabling the water to pull the swarf (chips) out of the cut zone. Cut speeds of two to three times faster than traditional wire EDMs are reportedly achievable.

In addition, the wire path can be programmed to follow the support structure and remove support material in the cutoff process—rather than taking a straight cut along the face of the build plate—which saves time on the secondary machining process.

The Fast Wire EDMs are available in three models to handle build plates of 410 mm, 625 mm and 1,050 mm high.

Related Content

-

Extensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

How to Put AI to Work in EDM

AI streamlines EDM with dashboards, NFC integration, data extraction, wire cutter design, G-code optimization and tool setter enhancements.