Space-Saving Five-Axis Provides Productive Mold Machining

The Grob G150 universal machining center and its spatial accuracy enhances its performance with complex, high-precision components.

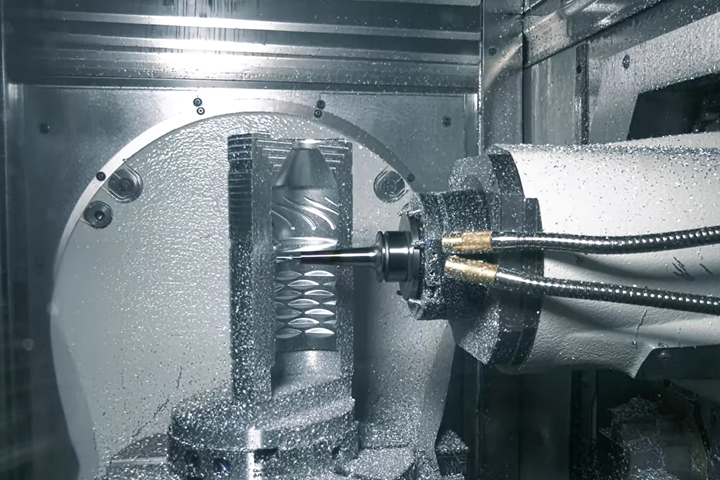

The G150 five-axis universal machining center from Grob Systems Inc. is a small but mighty innovation targeting moldmaking applications. It is equipped with features that provide a wide range of benefits including optimal chip evacuation via its a horizontal spindle position which reportedly permits the longest possible Z-travel path in its machine class. Tool changes occur outside of the work area, which eliminates chip interference.

Three linear and two rotary axes enable five-sided machining and simultaneous interpolation. The machine’s distinct axis arrangement makes overhead machining possible, offering operators improved accessibility for a broad range of part sizes. It also minimizes the distance between the guides and the machining point and permits a large 230-degree swivel range in the A-axis.

Torque motors in the A and B axes ensure dynamic and wear-free machining of parts. According to the company, a tunnel concept allows the largest possible component — even when using very long tools — to be machined within the work area without collision. The Grob G150 has working travels in the X, Y, Z axes of 450, 670 and 665 mm, and maximum speeds of 50, 40 and 60 m/min, respectively.

The video below illustrates how these features enabled the machining of a bottle mold with a high gloss finish.

When used in conjunction with the Grob pallet tower storage system (PSS-T) which automatically removes and loads pallets for unmanned operations and/or lightly attended shifts, users receive the power of a larger moldmaking machine option coupled with a space-saving tower design that helps provide ideal access to the work area.

Related Content

-

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

Problem-Solving Powers MPP's Growth

Long-time Michigan mold builder expands its capabilities, incorporating molding and embracing automation, while maintaining its collaborative problem-solving approach and apprenticeship program.