Tool Steel Improves the Efficiency of Molds, Injection Molding Using AM

AddUp partners with Swiss Steel Group to introduce Printdur HCT, enabling manufacturers to significantly reduce production cycles using conformal cooling channels.

AddUp will soon be releasing Printdur HCT, a tool steel optimized for injection molding that meets all customer requirements such as corrosion resistance, hardness and wear resistance for injection molding applications.

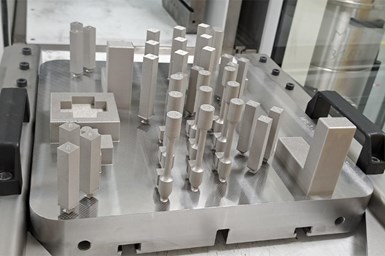

The Printdur HCT was developed by Swiss Steel Group (SSG) based on the conventional standard tool steel 1.2083/AISI420 tailored for additive manufacturing (AM) with focus on powder bed fusion machines like AddUp’s FormUp 350. Following strict internal manufacturing readiness level protocols, AddUp’s engineers were able to achieve up to 50% improvement in build speed without cracks and extremely low porosity, ensuring more than 99.90% material density when compared to the standard material.

The company also says surfaces can be built up in excellent quality and without any smoke residue. The Printdur HCT material was designed for the requirements of injection molding and can significantly reduce production cycles using conformal cooling channels. Most of the internal cooling channels can be optimally built to a sufficiently good quality, without any support structures.

Because of an enhanced hardness range of 53-57 HRC and high wear resistance Printdur HCT offers an improved and longer service life for mold inserts. With simple, one-step heat treatment at 540°C, Printdur HCT achieves ~53 HRC hardness and is ready to be used for injection molding applications because the material can withstand high temperatures without losing hardness.

Moreover, because the material is produced without nickel and cobalt, significant damage to the environment and the operator could be avoided.

Printdur HCT’s manufacturing readiness level 3 has been achieved, which makes it ready for producing high-quality proof of concepts. Currently being used on the FormUp 350 machine located at AddUp’s Tooling Competence Centre in Aachen, Germany, Printdur HCT is immediately available for prototyping and once fully developed will be available for end-use production parts.

Related Content

-

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.