Design Modeling Package Integrates Tools to Organize Projects

Xcentric Mold & Design (Chesterfield, MI) prides itself on being a low-volume, short-run, complex custom mold specialist and a prototype mold provider with leadtimes as little as one to15 days.

According to Xcentric President Damon Weaver, using KeyCreator 3-D Direct CAD software from Kubotek USA Inc. (Marlborough, MA) allows the company to tackle projects such as a fishing rod holder and an industrial sewing machine with incredible efficiency.

The company motto at Xcentric is to work less and make more. Weaver notes that since he pays his employees a competitive wage, it is difficult to demand less production that usually comes from a 40-hour work week. “Therefore, the burden is on us to provide everything our employees need to meet the demand in a 40-hour work week,” he states. “For decades people have worked endless hours to bring more home to their families, but in 2009 many found themselves without a house, a job and sometimes without a family—solely because the very job they relied on wasn’t there anymore and when it was there it did not allow time for the family. I was very discouraged by this, so I worked to create an environment where we can still make good money and have time for the family.”

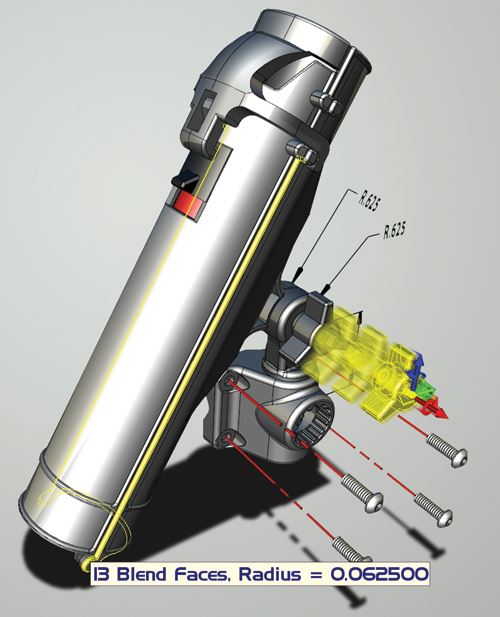

KeyCreator is the key to Weaver’s business philosophy. “KeyCreator seamlessly integrates powerful and accurate tools to organize our projects efficiently,” he states. “We can work with our customers’ CAD files even if they are not perfect. In cases where we need to suggest draft modifications or blend modifications to the customer, we simply import a Step file and with Kubotek’s advanced feature recognition we are making the required changes to the customer part in minutes. We then export a Step file back to them with the incorporated changes for their approval.” This capability allows Xcentric to keep the job moving forward since the designers do not have to wait for the customers to update their file in-house, which also appeals to the customer’s bottom line as they do not have to use their resources for these changes. Xcentric usually does this at no cost to the customer.

Xcentric’s “move-forward mentality” has no room for back pedaling, Weaver adds. “Once the sales engineer secures the job, our customers can rest assured the job is in move-forward-only mode,” he says. “Even when our customers want to make a change on the fly, they often find that the job is already complete. But they can still implement the design change ahead of schedule since the change can be integrated seamlessly.”

Solid Modeling Advantages

Weaver emphasizes that Xcentric’s business philosophy starts with a “bullet-proof” design system. “Design is the Bible,” he states. “All information comes from the design. Xcentric makes no exception to utilizing the best freeform solid modeler on the planet to accomplish our needs. We believe this software is the most powerful, intuitive and cost-effective program with results we can rely upon. We used it to standardize our process.”

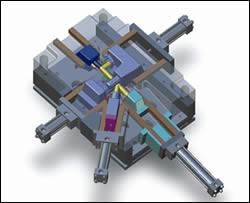

Other companies use solids only briefly in their designs or they design in surfaces, then convert to a solid manifold, but Weaver points out Xcentric has taken the training Kubotek offered and gone one step further, developing its own rigorous training program to teach its designers how to design molds using solids. The designers start out using easy CAD files, then progress to more complicated files as they learn. “We teach them to keep the part as a solid manifold—as it was designed in its native form and then split and develop the mold around it,” he elaborates. “For the untrained individual, this process can be very discouraging—but once mastered one can literally design two to five molds per day, per designer.”

Weaver explains that most software “forces” the mold designer to work with surfaces for parting line run-off, but KeyCreator’s features allow the designer to leave the solid as a manifold body and split the parting line with ease, for both complex and simple parting lines. “Any mold builder can use solids for simple parting lines, but when the parting line is complex, they revert to old school surface techniques such as creating tabulated surfaces and complex splines,” he says. “This gives us the edge in our design department as we can fully design a complex mold and be machining on it in the same day using the robust solids functionality of KeyCreator. We tried this with other systems and it just didn’t compare; we had to revert back to old school techniques.” Using this faster method has allowed Xcentric’s designers to build a design that is conducive to all departments of the mold build process, thus making the whole process quicker. For example, Weaver points out when creating parting line run-off, sometimes it is easier for the CNC department to clear an area where the sweeping parting line meets a flat. With solids, the designer can just create a moat around the area in seconds, which allows the CNC programmer to cut it as is with no prep work.

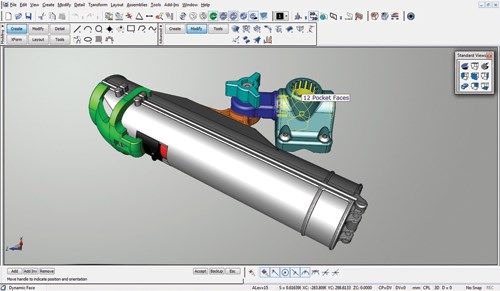

Weaver points out that the aforementioned Rapid Release Fishing rod holder is a good example of the company’s capabilities. “We designed the assembly from concept to reality in 10 days,” he states. “We then completed the molds and manufactured parts in 15 days. This assembly has 10 components and was awarded a United States Utility patent for the ability of the rod holder to disengage the back half while setting the hook—thus releasing the fishing rod.”

KeyCreator also can insert a deep complex area of a mold so the benching department can reach an area that needs polish in a matter of minutes, Weaver adds. Without KeyCreator that same task can take hours of surfacing and trimming with the old school methods.

Designing electrodes for EDM burning also is quicker with KeyCreator. “It is as simple as creating a blank size over the area and performing a Boolean subtract,” Weaver says. “Compared to the old method of copying and trimming and extending surface, this is light years faster. We estimate that we reduced our EDM design time on a job, by nearly 80 percent.”

Additionally, Weaver reports the company’s CNC programmers are quite happy with KeyCreator. “They are easily able to remove features they do not want to machine,” he explains. “KeyCreator recognizes features such as pockets, ribs, bosses, blends, chamfers, holes and many others that the designer and CNC programmer alike can remove or change with the click of a button. The old school method would require the CNC programmer to replace features they don’t want with complex cap surfaces.

“Once the designed mold hits the floor, we are off to the races!” Weaver adds, “The components are split up between the departments—where through proprietary processes and tools—the design becomes reality. Our customers are literally knocking our doors down to manufacture the parts, their suppliers said they could not—due to complexity or leadtime issues.”

Weaver believes KeyCreator is the “most intuitive” CAD software currently available. “It adapts to our move-forward mentality,” he affirms. “It is the right tool for the projects we tackle.”

Related Content

How to Clean and Maintain Molds With Intricate Conformal Cooling Channels

A water-based, eco-friendly plastic mold cleaning system helps Rankine-Hinman Manufacturing restore flow rates and avoid big-ticket failures on complex and costly molds.

Read More3D Printing Accelerates R&D Process For Prototyping Molds

Utilizing Axtra3D’s additive technology, LSI Solutions, a medical equipment manufacturer found the compatible machine it needed to accelerate its R&D process for prototyping molds for medical devices.

Read MoreLaser Welder Yields Fast, Precise Mold Repair

Intralox's integration of the Alpha Laser ALFlak has significantly improved its toolroom efficiency when it comes to difficult welds and urgent repairs.

Read MoreAdvanced Mold Monitoring for Efficiency

ITW Body and Fuel optimizes mold performance through real-time monitoring and integrated asset management, achieving significant reductions in downtime, scrap rates and maintenance costs.

Read MoreRead Next

QR No Longer on the QT in MMT

It wasn’t all that long ago that readers had to put up with doing a fair share of work and waiting to get free information.

Read MoreSoftware Facilitates Art-to-Part Capabilities

Design/manufacturing software allows moldmaker to produce prototype parts in less than seven weeks—something few moldmakers can accomplish.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More