MMT Memories: A Moldmaker Centerfold

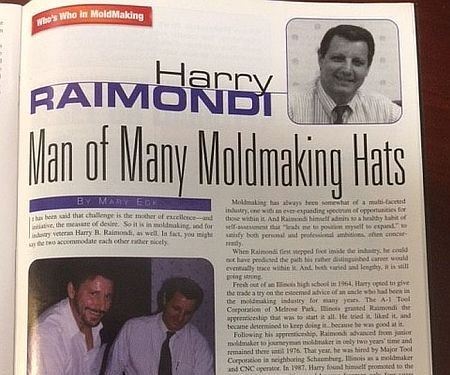

MoldMaking Technology’s 20th anniversary brings back an abundance of memories, including this 1999 feature about Harry Raimondi of (then) Bales Mold Service, a moldmaker “centerfold.”

I remember it almost like it was yesterday, but it was nearly 20 years ago now. I had just begun working as a public relations professional for Bales Mold Service (now Bales Metal Surface Solutions) in Downers Grove, Illinois, and in researching and building a list of publications to work with, I discovered MoldMaking Technology Magazine.

I had never heard of MMT before, but I was excited that there was actually a magazine dedicated to our industry, and I quickly contacted Christina Fuges to find out more. Zip forward 20 years and here I am, senior editor of MMT working alongside Christina and I could not be prouder. I also could not imagine missing the chance to call my friend Harry Raimondi at Bales to reminisce a little.

In September, Harry will have worked at Bales for 22 years. Prior to that, he was a journeyman moldmaker, working for such companies as A-1 Tool Corp., where he served his apprenticeship, Major Tool Corp. and eventually Cutco Industrial Supply, where he got his first taste of being a sales rep and consultant. He liked it. Then, in 1996, Harry joined the team at Bales. I came on the scene about two years later and that’s when we first worked with MoldMaking Technology to feature this moldmaker-turned-sales rep.

“I remember being interviewed by Mary Eck,” Raimondi says, “and when the issue came out I remember Steve (Bales, the late founder and president of Bales Mold Service) walking over to me with the magazine in his hands and saying, ‘Hey, Raimondi, you’re going to love this. You’re a centerfold!’

“I hadn’t seen the magazine yet because we only got the one copy in the mail at that time,” he adds, and he heard from several of his colleagues and co-workers who were anxious to acknowledge his newfound celebrity. “I caught a lot of sh**, basically.”

But MMT became an important tool with which to promote Bales’ services, Harry says. “Seventy-five percent of our work is still focused on molds. We were so glad to be part of MoldMaking Technology—and not just with articles, but also by participating at the Moldmaking Expo (now Amerimold), exhibiting and giving presentations,” he says. “To see where things have gone both for the magazine and for Bales over the last 20 years has been interesting. Amerimold is still the top show for us, and with the magazine has helped the company grow. I can remember walking away with 150 leads from the show. The only shows we do religiously now are NPE and Amerimold. Amerimold was without a doubt the show that got us headed in the right direction.”

As Harry and I talked, he glanced over the article about himself, pausing to say to me, “You know, Steve is quoted in here saying, ‘Bales hasn’t had a salesman in 18 years. But we’d worked with him for several years, knew his reputation and just thought it was a good fit. And we were right.’ That’s really something.”

Looking at it today, Harry says MoldMaking Technology is stronger than ever. “Back then, they needed filler so they asked me to do the article! It was fun,” he jokes. “Seriously, though, we tip our hat to MoldMaking Technology that they were able to connect with the industry and become a leading publication for the industry.”

Related Content

Ultra-Fast Femtosecond Laser Texturing Helps Produce EV Lighting Lens Molds

Edge-lighting lens patterns present moldmaking challenges that ultra-fast femtosecond laser texturing technology can overcome.

Read MoreMold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreAutomating Mold Polishing With AI-Powered Robotics

Empowering human workers and harnessing the precision of AI-driven robots may help streamline the polishing process for some molds and tooling.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read More