JMMS Sees Growth with Focused Program Management

Dedicated project managers present the company as a dedicated partner, not just a supplier.

Not quite five years ago, JMMS, Inc., of Easley, South Carolina, was featured in this magazine after having earned our 2011 Leadtime Leader Award: Small Shop Honorable Mention.

“I remember completing the entry form for the Leadtime Leader Awards,” says Rich Martin, business development manager. “We put hours into it, going through files and more files. It wasn’t the entry form as much as it was the fact that we’d been in business for 25 years by then, and nobody had taken the time to keep score.”

Martin credits the Leadtime Leader entry process with giving the company that extra nudge it needed to begin getting a comprehensive business growth plan in place that included systems for tracking operations throughout the plant; budgeting and forecasting; and measuring competitive profiles, delivery times and efficiencies.

“It became much clearer to us who we wanted to be when we grew up, so to speak,” Martin says.

Investing in Partnership

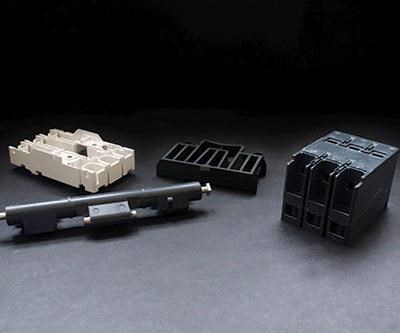

In 2009, when most other companies were battening down their hatches against a recession, JMMS surged ahead with substantial capital investments and hiring of top-level personnel that would aid in the advancement of a newfound business strategy. Specifically, JMMS spent close to a million dollars to purchase a new OKK HM1250S horizontal machining center to expand its capacity for building very large molds for a good customer. Then the company set out to develop close, long-term business relationships by creating three project manager roles—one to work closely with thermoset customers, one to manage thermoplastic, and the third for cultivating and maintaining die cast customers. The result was a 40 percent increase in sales, signaling that the new strategy was a solid one, Martin says. Seven years later, it still is.

“Today our customer list is a much tailored version of its former status,” Martin explains. “Our business model comprises targeting companies that are engineering-driven. They view JMMS as a dedicated partner, not just a supplier. This is a world-class caliber of customers we’re working with.

“Each customer now has a go-to guy with the expertise required to get their projects done right. We hear all the time how much they like having dedicated project managers that can respond quickly to their needs. We see no weeping or gnashing of teeth over problematic customers either. It works.”

Since 2011, JMMS has added 10 new die cast customers, three new thermoset customers and nine thermoplastic customers to its select list, which includes OEMs in the power generation, automotive and light packaging industries.

“These companies are looking for the whole package, not just to cut costs,” Martin says. “They want full-service benefits. Today, we can offer that.” For example, JMMS builds all of the tooling, and provides mold maintenance and repair services for a major thermoset molder’s North Carolina facility. The company also manages all tooling, including engineering changes, maintenance and repair, for a light packaging OEM customer in South Carolina. Anything that is too large for the company to handle is subcontracted, and that subcontract is managed by a JMMS project manager.

JMMS also maintains a ISO 9001:2008-certified quality management system as a way to reinforce its project management qualifications for overseeing each phase of a mold’s lifecycle, from design through to production and maintenance.

The company employs 27 workers, including one apprentice, at its Easley plant, and has grown the staff at its Dongguan City, China, location from three to five with the recent addition of two more mold designers. A business director and program manager round out the team there. Customers also can benefit from JMMS’s “follow the sun” design and development strategy, which is intended to help speed productivity by providing 24-hour continuous design and development services.

Equipment-wise since 2011, the company has added a 2013 Mitsubishi MV2400S wire EDM to replace an older machine and bring this work back in-house. A 2000 Roeders RFM600 high-speed vertical machining center has also been added, and an upgrade was made to JMMS’s Cimatron CAD/CAM software, which Martin says is “phenomenal on roughing and very fast.” As a final step in its new business strategy, JMMS created a maintenance and repair department that is separate from general shop operations to begin promoting that side of its value-added services.

100-Percent on Time

JMMS’s focused project management strategy has enabled the company to deliver tooling when the customer requires it—another key cog in the wheel of the company’s success.

“In 2015, we delivered 100-percent on time,” Martin says. “We have an excellent quality manager, and the results of a recent ISO audit revealed zero defects. If we detect any chance of a mold being late, it is identified in our project meeting, and we alert the customer. Then steps are taken to alleviate the issue.”

Every project begins with a routing meeting centered around how JMMS plans to build a tool. “Everyone who will have a hand in a project is at the table,” Martin explains. “Every step and every inch of the tool is examined, piece by piece, and we determine one of two things: make it or buy it. This pertains to everything from bolts to bases, programming, engineering, toolmaking, assembly, EDM wire, CNC, and more. Hours are assigned to each step. Maybe the quoting team estimates 500 hours for a job, but the routing team, during its meeting, quotes 650. Now the creative juices get flowing as we work together to cut that extra time out of the job.”

Martin asserts that it’s not some “secret machining center” that provides the company’s competitive advantage. Rather, it’s being completely transparent and honest with customers, in addition to providing focused program management. “We build tooling here and in China,” he says. “Where it’s built depends on what’s driving the market. But we’ll never send a mold or any project to China without a customer knowing it. Our customers are always part of the process.”

Going forward, Martin says the company is once again poised to make further capital investments and is busy investigating its options. Among the items on the table are changes to plant layout and floor layout, as well as adding more automation in the form of palletizing, robotics and five-axis machining.

“Getting a P.O. from a customer is easy,” Martin says. “The trick is to keep the relationship with the customer in honeymoon mode. We cherish our customers. We listen to them. We thank them, sincerely and often.”

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreTooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreRead Next

JMMS: A Family’s Legacy

Over the past 23 years, JM Mold South (Easley, SC) has reinvented itself a number of times—beginning with a focus on consumer molds, a diversification into automotive molds, and a name change to JMMS as the torch passes from one generation to the next.

Read More2011 Leadtime Leader Awards: Small Shop Honorable Mention

JM Mold South, Inc.: Constant Reinvention Results in Growth, Success.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More