Heidenhain TNC Controls Streamline Mold Manufacturing and Global Connectivity

Five-axis machines with the right controls are a key part of a connected system that yields better, faster work.

Krones Inc. in Franklin, Wisconsin, is a subsidiary of a company based in Germany that routinely manufactures redundant parts in its plants throughout the world. Krones recently developed a way to streamline this process and provide optimized parts to end users faster and better.

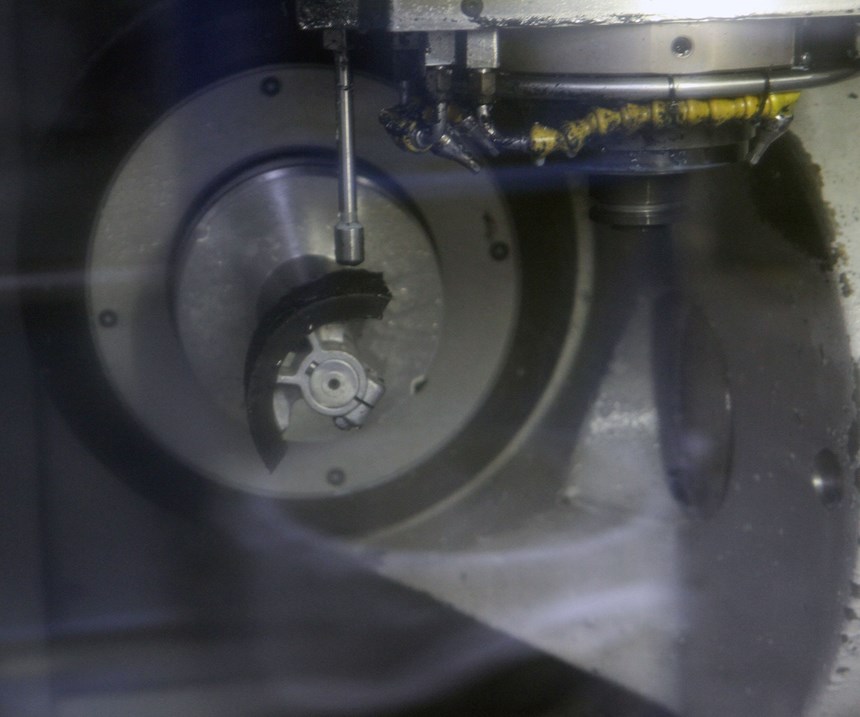

The approximately 8,000-square-foot moldmaking area within Krones’ 300,000-square-foot facility is equipped with four Heidenhain iTNC 530-controlled machines doing cavity work. It also houses two smaller auxiliary machines, a quality control department with a coordinate measuring machine (CMM) and an assembly area. This Krones location is primarily focused on manufacturing and supplying parts for its large blow molding, filling, labeling, and packing operations installed throughout North America, Central America, and the Caribbean. Common jobs include manufacturing molds for stretch blow molding machines that produce PET plastic bottles for water, soda, and other liquid products. A typical part-lot size is 40 pieces (20 mold sets) in an average four-hour cycle time.

“We are making very tight-tolerance, similar mold parts at each location, all requiring high accuracy and highly-polished surface finishes down to Ra (arithmetic average of the roughness profile) right out of the five-axis machine,” John Vincent, Krones’ Head of Manufacturing Technologies, says.

As part of the pilot program started three years ago, Krones took steps to connect to its affiliates in China and Germany. Using a Forcam digital software system (similar to Heidenhain’s new StateMonitor software), staff programmed the Heidenhain controls in the three locations to connect and interact as required.

“This setup allows us to measure the actual usage of any machine at any time. Plus, when a machine stops, next-step protocols are provided including the ability to enter cost codes for tracking the cause of any downtime,” Vincent says.

“We completed the part that same day for customer review. And this is a part that probably has a cycle time of five hours, so it isn’t something on which we can minimize run time. This process is one that our customers continually request be done quicker, and we are happy to now be able to do it.”

Making the Right Connection

There is connectivity among all 65 CNC-controlled machines at the Wisconsin facility. To test the connectivity, they ran programs from both Krones plants in Germany and China, which were then selected within their software systems in Wisconsin and ran without any issues. This is particularly helpful for customer development work, Vincent says.

For example, Krones recently had an order for a new bottle on a Monday and designed the mold that same day. Vincent then sent an email to a Chinese colleague, whose moldmaking department has six Heidenhain iTNC 530s, requesting a program for the project. When they came into work Tuesday morning, they loaded the program from the Chinese colleague into the iTNC 530 and started running it.

“We completed the part that same day for customer review, and this is a part that probably has a cycle time of five hours, so it isn’t something on which we can minimize run time. This process is one that our customers continually request be done quicker, and we are happy to now be able to do it,” Vincent says.

Connected Machining

Krones Inc. has been using the Heidenhain TNCs in its moldmaking departments for some time, with change-outs to updated machines approximately every five years. “I’m a huge fan of the Heidenhain controls. Particularly in the moldmaking industry, these controls have a leg up on the competition as far as being able to achieve excellent and accurate surface quality at high speeds,” Vincent says. He likes many features, he adds, including the manual probing routine on the machine via soft keys right on the control.

Krones machinists receive training on the controls, though Vincent adds that once his employees learn the Heidenhain control, they usually don’t want to go back to another. The TNCs are conversational, and while Vincent admits that many new employees are hesitant to try something new, after some training they don’t want to run anything but the TNCs.

Vincent adds that he and his staff find many TNC control features easy to use, making special mention of the ability to do things on the fly and add checking programs by the operators, as well as the way the tool table systems work. Krones uses a tool data management software that integrates well with the TNCto assign a number to every tool assembly in the plant. Using the TNC, they can call out a number, and no matter where it is in the machine tool magazine, the operator can pull it.

“It’s easy since you don’t always have to have tool number one in pocket number one. This is a real benefit to us and not something I see with other controls,” Vincent says.

Here, Krones Inc. staff is using the extended tool management feature where they can load and unload from the list of tools by simply using a mouse to drag and drop. Plus, a tool usage list provides more details, and an import function allows for reading and exporting CSV files.

Another important TNC control feature used by Krones is the Heidenhain DNC option, which provides the ability to communicate with external Windows applications. The shop also uses the Remote Desktop Manager, enabling the user to operate one or more Windows PCs directly from the TNC. “We frequently use the TNC Remote to load programs into the machine’s control from various locations,” Vincent says.

Krones also employs a unique manufacturing system in a different area of the shop that uses an iTNC 530 control on a machining center that produces pallets for bottle-labeling machines. In this system, Krones engineers configured a waterjet into a five-axis machining center. They were able to use the features in the TNC control to create multiple setup kinematics to handle using the normal milling spindle as well as the separate auxiliary waterjet feature.

“We are using a GF Mikron machine with a pallet changer (up to 21 parts), and all the data is set up so that an operator can pull in the appropriate program. Then the machine moves successfully between milling and water jetting as needed,” Vincent says. “This connected machining has been going strong on a daily basis over the last year, and we are now working to expand it to other departments.”

“This connected machining has been going strong on a daily basis over the last year, and we are now working to expand it to other departments.”

Importance of Training and Support

To keep this large organization at the top of its game, Krones’ culture includes daily employee support and training as needed.

“As we look to the future of manufacturing and global connectivity, we know that it is important to know what today’s advanced capabilities offer. We understand that it’s beneficial to have skilled staff who can and want to interact with our machines to customize and optimize the end products,” Vincent says.

Vincent explains that continuous improvement is part of this process. They set the program up so employees can meet in groups weekly. He also adds that the company provides both in-house and external machine training to Krones employees. Last year, for example, eight employees were sent to Heidenhain’s North American headquarters in Schaumburg, Illinois, to participate in a four-day TNC control training session.

Training at Heidenhain encourages full use of conversational control in various ways and enables greater creativity for the operator to fully use its features. “I’d say 95 percent of Krones programs come from a CAD system, but when using a Heidenhain control, our operators can easily fine-tune them, right at the control as needed. This access yields improvements that the company would not realize otherwise. Plus, it allows our operators to take ownership of their work,” Vincent says.

Related Content

Velosity Earns EcoVadis Bronze Medal for Sustainability Performance

Rating reinforces Velosity’s efforts to align with global sustainability standards and customer expectations.

Read MoreMMT Chats: Championing Moldmaking Recruitment

Production manager is doing his part to help transform skilled trades recruitment through strategic advocacy and digital engagement.

Read MoreCertified Quality Management for Plastics Professionals – Materials to Tooling to Recycling

Why is certification of a shop’s quality management system to ISO 9001, AS9100, IATF 16949 or ISO 13485 so special? What does the certification signify? And what supports the paper behind the framed certificate?

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreOvercoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read More