Conformal Cooling

Metal 3D Printer Combines Laser Sintering and High-Speed Milling

Laser sinter metal powder and perform CNC machining of tooling components in the same machine.

Read MoreFlat Centering Unit Enables High-Precision Centering of Inserts

Meusburger designed its E 1307 centering installs with minimum space, providing inserts with maximum space utilization within the insert.

Read MoreAM Platform Recycles Powder for Safety and Efficiency

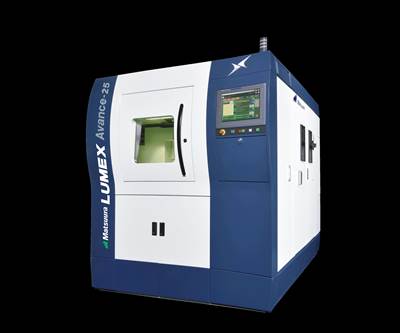

The Lumex Avance-60 is a product from the Matsuura Lumex Avance series, which are now available in North America from Matsuura Machinery USA, Inc. The series are made of powder bed, metal additive manufacturing (AM) platforms with subtractive capability that combine laser sintering and high-speed milling.

Read MoreCentering Unit Is Flat for High-Precision Centering of Inserts

Meusburger designed its E 1307 centering installs with minimum space, providing inserts with maximum space utilization within the insert.

Read MoreVacuum Brazing Meets Additive Manufacturing for Optimized Conformal Cooling

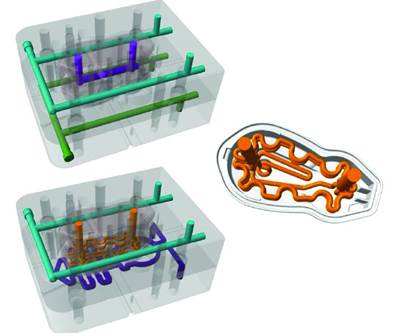

Renishaw and Liechtenstein-based Listemann Technology have joined forces to service moldmakers with the optimum conformal cooling solution. Depending on the application and desired reduction in cycle time, the companies now jointly design and create conformal cooling channels either through vacuum brazing, laser sintering or a combination of both to find the most suitable and cost-efficient design for their customers.

Read MoreMachine Combines Additive and Subtractive Processes for Quick Turn of Custom Parts

The Lumex Avance-25 is a product from the Matsuura Lumex Avance series, which are now available in North America from Matsuura Machinery USA, Inc. The series are made of powder bed, metal additive manufacturing (AM) platforms with subtractive capability that combine laser sintering and high-speed milling.

Read MoreReshaping Moldmaking

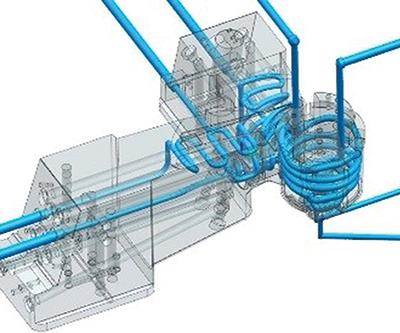

Metal-printed components like conformal cooling inserts can improve existing production processes.

WatchMay the Force Be with You

Unlocking the true potential of magnetic workholding for machining mold bases and inserts lies in understanding clamping and machining forces.

Read MoreThe Designer's Edge: Stationary Vent Pins and Inserts

Stationary pins or inserts, which are sometimes a necessity to assist with venting, should be designed with ease of assembly and disassembly in mind..

Read MoreHigh-Feed Tool, Deeper Cut?

Thick inserts make a high-feed tool this shop’s top choice for heavy roughing operations as well.

Read More.png;maxWidth=970;quality=90)