Thinking Big and Easy

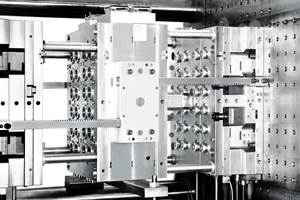

It’s what's between the platens that matters, says Hasco Engineering Manager Brenda Clark at NPE2018. “It’s all about the precise amount of space required to get the product produced in the minimum amount of mold base, yet with the best quality and substantial steel to improve part quality.”

“Think big and simple with standard components” was the general theme at HASCO’s Booth earlier this month at NPE2018. “Think big, economic, standard parts,” Hasco Engineering Manager Brenda Clark says. “What was also big was our presence this year, we now have a complete sales team in the USA.”

Not only did Hasco have its biggest booth in years at a 20’ x 30’ in the South Hall, it also had its standard components running in three molds throughout the West Hall, highlighting very unique technology and applications that are possible with standard components.

One demo mold produced an injection-molded business cardholder, which was 3D additive overmolded on an ARBURG special thermoform machine, with assistance from Kistler and FormTech, a New Hampshire mold builder, which is one of several U.S. moldmakers HASCO collaborates with using metric components, plates and hot runner systems.

This project started with a complete Hasco mold base assembly, which creates the part. Then the part went into a holding pattern for a labeling process placing an Industry 4.0 tracking or a QR code to show where and when the article was molded. Finally the plastic part was lifted up into an ARBURG freeformer additive machine, which prints the NPE attendee information onto the injection molded part allowing the parts to be customized for each attendee upon request.

The second mold produced a radius gauge giveaway. The radius gauge is a machine nozzle specification gauge for an injection molding machine screw nozzle radius measurement. Molders need to know what that radius is, so they can machine it onto a sprue bushing within the injection mold. This helps to keep drooling and leaking to a minimum between injection molding machine and the mold.

Hasco worked with JMMS for this mold build,” Clark says. Hasco supplied the hot runner valve gate system and all the plates and components to build the tool, including a very economical bolt-on hot runner valve gate system for the standard mold base. This tool took a metal insert and overmolded it. Arburg vertical machine technology is capable of overmolding with different insert and molding thicknesses. “They are varying the part thickness via the same hot half, using a valve gate system that permits flow adjustment,” Clark says.

The third mold focused on components within the popular Wittmann Battenfeld booth on a 110-ton machine making a toy building block built by their mold builder Demel. This mold featured fittings to hard plumb the waterlines on the outside of the mold instead of using hoses that must be looped around, sticking out, wasting space and making mold installation difficult. The part then moved onto the automation cell. “Wittmann Battenfeld hard plumbed the mold, which then uses a limited amount of space, making installation easy, clean and reliable,” Clark says.

Back at Hasco’s booth, teams from Hasco America, Canada and Mexico demonstrated and explained various technologies on display. And, Vice President of Sales & Business Development for HASCO, Mr. Dirk Paulmann was on site to support the North American team. I had a chance to chat with Mr. Paulmann for a few minutes to learn about Hasco’s five-year Industry 4.0 initiative as well as a little history on the company’s customer appreciation Motorcycle Run each year. Mr. Christoph Pischel, the Business Development Manager for North America and Asia was also on hand.

The big push at the booth was its interactive Go Web Portal. “It’s all about simplicity, beginning with the website,” General Manager Rene Eisenring says. “Hasco has put a lot of energy into its website to make it simpler to find a part.”

The new web page (www.hasco.com) gives access to product information, sizing and machining information. It also offers a free customized mold assistant to build any mold required—a standardize A or B series, floating plate, a three-plate stripper mold, etc. The assistant not only gives you a bill of materials, it also provides the 3D CAD that directly dumps into the open CAD system through Click2CAD. “This is very streamlined. You get a native file and the designer is then ready to put in their cavities and cores and make it their own tool,” Clark says.

Hot runner components were also showcased, including an extension of Hasco’s Vario shot hot runner nozzle, which was introduced last year and works on heat expansion to seal. Hasco realized it's important with some materials and applications to actually screw that nozzle into the manifold, instead of relying on it to seal with heat expansion. The benefits are better sealing and ease of assembly and disassembly. “When you have to perform maintenance or a color change, you can now lift out the whole manifold and the nozzles come with it. It’s all about ease of maintenance,” Clark says.

The mold’s maintenance is also important to Hasco. They showed a wide variety of high quality greases from non-migrating, high temperature to food grades. The non-migrating grease that does not move is ideal for cleanroom applications because where ever you apply it on the steel, it stays. It is also food grade, non-silicone and high temperature. “It reduces the amount of contamination. It doesn’t move or flake off, eliminating any additional cleaning process. The part can go right from production into a plating process,” Clark says.

This special grease is also highly recommended on all of Hasco’s DLC (diamond like carbon)-coated components. The DLC coating also allows you to run dry. You don't even need to use a grease. The key is using only a light layer and even wiping it off should you choose to use the grease.

Hasco also introduced water manifolds, new collapsible cores, latch locks and a lift ring with a built-in spring held toggle that helps the toolmaker lift the mold. They can set it, go over get the hook come back and it's in the same spot.

Hasco has always focused on what's new and what’s needed in a complete mold build. As Clark says, “It’s what's between the platens that matters, and then some.” She explains that it’s all about the precise amount of space required to get the product produced in the minimum amount of mold base, yet with the best quality and substantial steel to improve part quality.

“It’s about economics. You need to be able to build the mold smarter, faster and economically. Standard products keep it simple and smart. Every component and product that we have helps you work smarter and saves you time.” Clark says.

Related Content

How to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection, there are many variables that can dictate the best option for moldmaking.

Read MoreCorrosion-Resistant, High-Hardness Mold Steel for Optimal Surface Finishes

Uddeholm’s premium Tyrax ESR can reduce polishing time by 40-50% and is suitable for long run production molds and high-performance plastics.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)