Sharpening Their Edge

Continued facility and equipment investment helps to maintain a focus on consistency in cutting tool design and manufacture for Seco Tools and Niagara Cutter. This includes two products developed to utilize the entire capability of the machine tools on the market today.

Share

Read Next

It has been more than six years since Seco Tools acquired Niagara Cutter and in that time $7 million has been invested in equipment and office/meeting space its Reynoldsville, Pennsylvania facility, where it manufactures standard and custom solid carbide tooling and HSS endmills and drills to the global marketplace. Operations are set up to also manufacture any Seco solid rotating tool. The goal here, according to Seco Tools President Robert Keenan, is product consistency: all tools can be built at multiple facilities. Consistency is key in cutter design. He also notes that it was a strategic decision to maintain the Niagara brand due to its strong recognition in North America for quality and reliability in high-performance carbide.

During the press event earlier this month key executives shared the company’s history, future plans and new product introductions. But before the technology specifics, they noted a few recent trends that helped gear their product development. These included smaller machine tools, more three-axis and five-axis machines, more challenging materials to machine including composites, more near net machining and not as much roughing, and software and tooling catching up machine tool developments. Two of the product highlights developed to utilize the entire capability of the machine tools on the market are the Stabilizer 2.0 and the Multi-Flute family of cutting tools.

The original Stabilizer heavy-roughing end mill was developed in 2003 for the reduction or elimination of resonant vibration. Today’s Stabilizer 2.0 can handle more feed than any other tool, improving throughput and opening capacity, according to Senior R&D Engineer Dennis Noland of Niagara Cutter. Basically, it allows you to do more with the same machines on the floor.

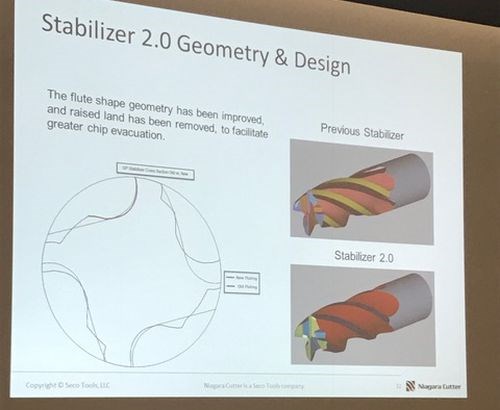

Noland goes on to explain the improvements: double chip load capability increases metal removal rates, the addition of 3XD length of cut, alternate corner radius, shank modifications, it is regrindable and offered in both cylindrical and Weldon shanks. Its geometry and design are also improved. Every flute has a constantly changing helix along its entire length, which is different for every flute and every flute is varied to a different index angle, which constantly varies along the entire flute length. The flute shape geometry has been improved and the raised land has been removed to afford greater chip evacuation. All of this means, continuously variable asymmetrical geometry delivers smooth, chatter-free cutting. It is available in diameters ranging from 0.125 inch to one inch in a variety of lengths, shank types and corner radii.

Multi-flute tools are a trend, says Jay Ball, Niagara Cutter’s solid endmills product manager. Its Multi-Flute family of solid carbide multi-flute end mills is Niagara’s fastest growing cutting technology. It’s all about optimized roughing (trochoidial) with these tools, says Ball. This product series offers smaller diameters down to 1/8-inch, necked versions with extended reaches and even a ball nose option for demanding 3D applications that require optimal performance and tool life. A notable addition to this line of products is an advanced chip splitter design.

Here are some tips he shared on how to effectively apply this method of machining:

- Machine tools should have good look-ahead capability.

- Optimized roughing programs require large amounts of memory.

- Ensure that the machine has high enough feed rate and spindle speed capability.

- For roughing toolpaths, adjust the machine tolerance limits for the smoothest toolpaths and optimum tool life.

- Use the optimum step-over and feed rate for each type of tool.

- Carefully consider the right programming software or software add on.

- Optimized roughing is best used by using the maximum length of cut possible

- Chip splitters or “corn cob” roughing tools can help relieve pressure if vibration occurs.

- Premium holders are required for optimized roughing due to their dampening effect.

After a tour of the facility, Keenan noted that to continue developing all of this advanced cutter technology $25 million has been flagged for future equipment investment.

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)