GF Machining Solutions Demos Additive Manufacturing Flexibility at Solutions Days

The DMP Flex 350 and new EDM technology for AM promises more efficient, clean and repeatable production of dense, pure metal parts.

Nearly 200 customers, 20 distributors and other guests descended on GF Machining Solutions’ headquarters in Lincolnshire, Illinois, this week to see what’s new in Additive Manufacturing, EDM and milling technology during its Solutions Days event.

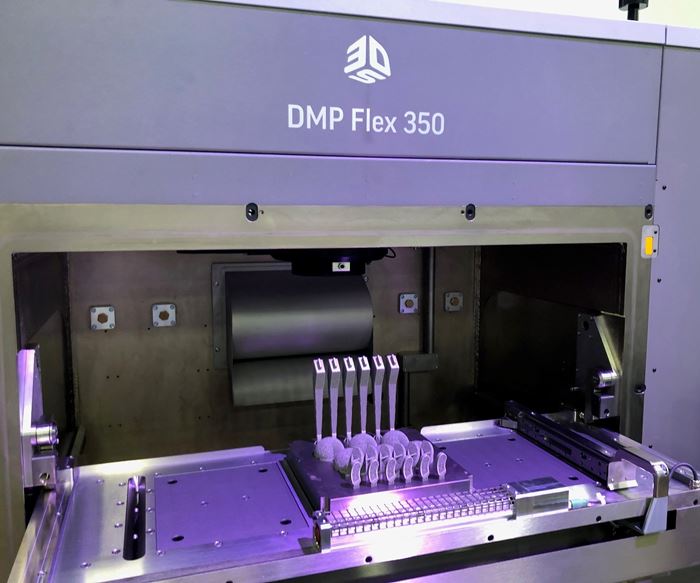

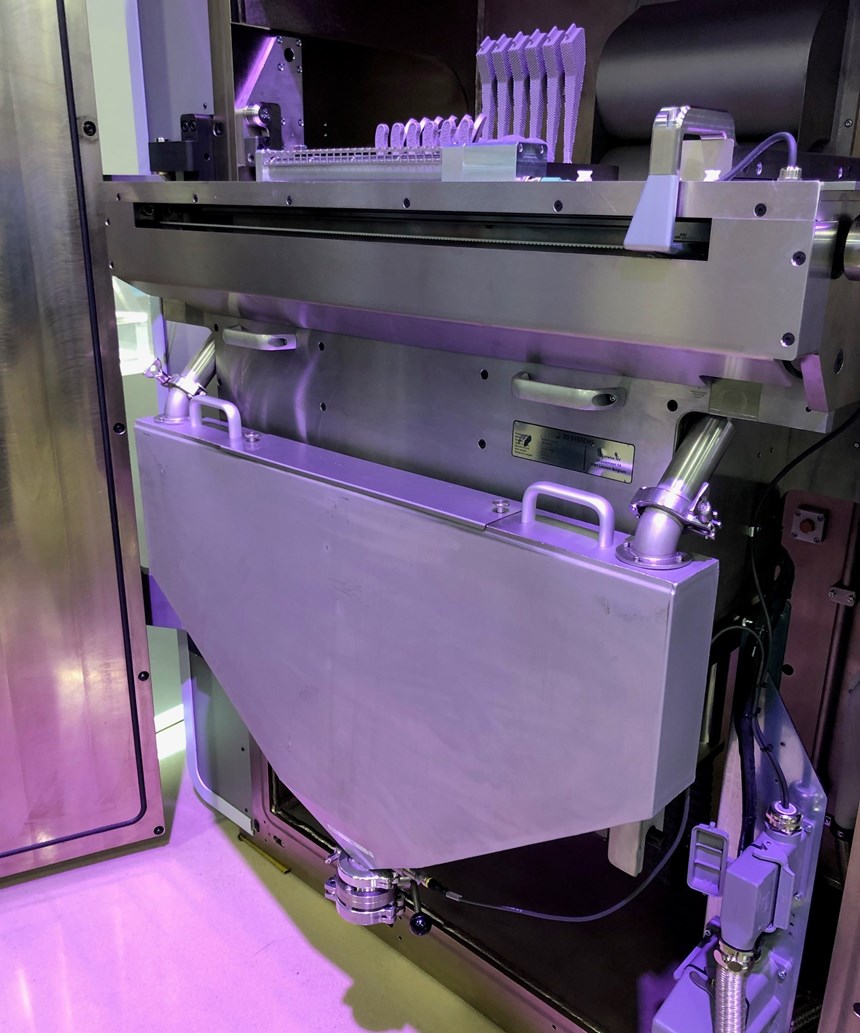

Making a particular splash was the DMP Flex 350 metal 3D printer, which GF Machining demonstrated during the event to show its “extreme processing flexibility, high throughput and outstanding repeatability.” With a maximum part build size of 275 mm x 275 mm x 380 mm, the company says the DMP Flex 350 enables more efficient production of dense, pure metal parts and includes improved gas flow technology for uniform part quality across the entire build area.

In addition, the Flex 350 features fast, bidirectional material deposition, which enables high-throughput 3D metal printing using materials like Iconel, titanium, cobalt chrome, aluminum and steel. Functional modules like the printer cartridge help to speed part production and material changeovers. “If your machine isn’t firing, you’re not making money,” Carlson says, explaining that the printer cartridge is designed to enable the operator to change out materials in about 30 minutes with like materials, two to three hours when changing to dissimilar materials, versus taking two to three days in other 3D printers. He explains that the use of cartridges also helps companies economize on materials. “All of the powder is included in the printer cartridge,” he says. “When you take that cartridge out, all the powder that is in the machine comes out with it, so it’s just a quick wipe down of the machine and all of the motion platforms, and that’s it. Because we use a vacuum to remove all of the oxygen during the additive process, it will not allow the material to become oxidized. This means you can use that powder until it is gone. No more waste.”

“The real big step for additive is not R&D and prototyping. It’s how we can get additive into production,” Jon Carlson, product manager, says. Last year, GF Machining announced its partnership with 3D Systems to develop a new generation of 3D printing solutions, and introduced the DMP Factory 500 at IMTS. Carlson emphasized how the combined expertise between the companies has helped build on the Factory 500 concept and bring the DMP Flex 350 (and DMP Flex 500, which offers three lasers in one machine versus one in the 350) to market. “What’s nice about the Flex is that it is the prototype and R&D machine. You can prove out your process on there and when you are ready to take that process into production, you can purchase and easily install the Factory component on it and go.”

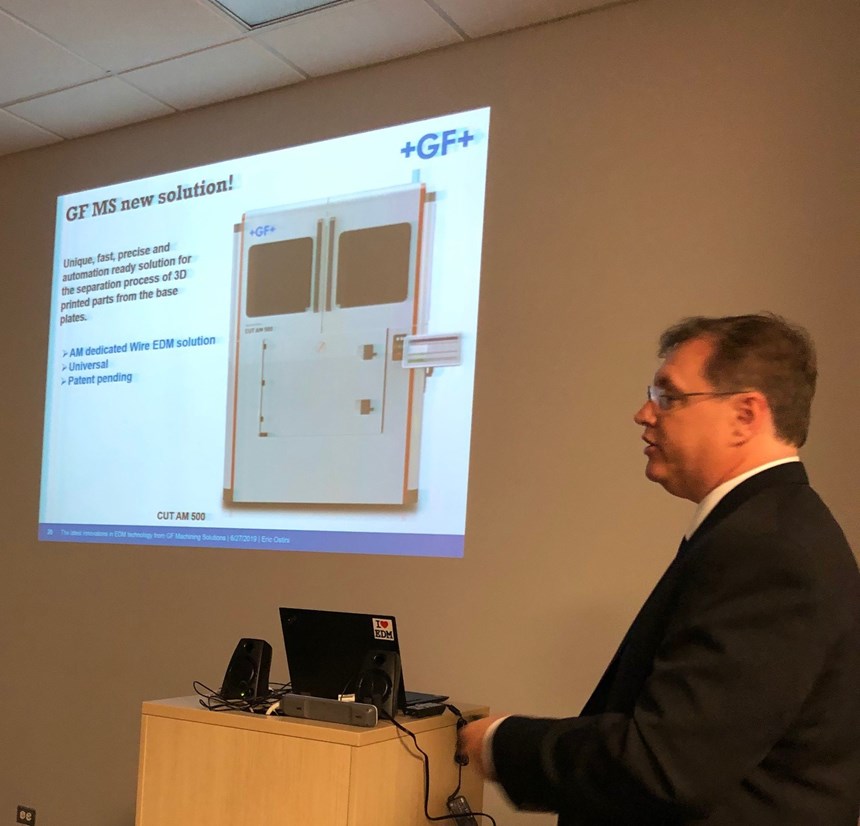

Sneak Peek of CUT AM 500 High-speed Horizontal Wire EDM

GF Machining Solutions also offered a sneak peek at the horizontal wire EDM they designed specifically for cutting off additive manufactured parts quickly and efficiently – and with less chance of damage. Unfortunately, the new AgieCharmilles CUT AM 500 was not on display at Solutions Days because the company will officially debut it during EMO in September, but some key details were shared.

According to GF Machining, the CUT AM 500 contribute to significantly faster overall production times and reduced operational costs. Using fully submerged EDM cutting, parts are cut from build bases without pressure, damage or material alteration, and there is minimal material waste compared to conventional methods such as bandsawing. An integrated swivel axis on the CUT AM 500 eliminates wire pinching and allows parts to gently fall down into a catch basket to decrease the risk of part damage.

In addition, an available clamping and referencing option allows users to move additive manufactured parts from one process operation – EDM, milling and texturing – to the next while parts remain attached to the build plate. In addition to faster setups, increased repeatability and greater accuracy, the setup option is automation ready for lights-out production. The CUT AM 500 features dual wire spools that allow for the use of reusable Moly wire for lower operating costs and less operator interference. The machine’s X, Y and Z-axis travels measure 19.69” x 19.68” x 19.68”.

Related Content

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)