Photo Credit: Getty Images

Even with the best fluid management procedures, water-based metalworking fluids will not last indefinitely and will require treatment and disposal. Typically, several situations can dictate disposal of the fluid: excessive contamination (oil, dirt, water, mineral build-up, metals, etc.), rancidity or filter malfunction.

Though some of these criteria are subjective, most dump, clean and recharge (DCR) decisions are made because the fluid is too oily and dirty or it simply smells offensive. More sophisticated controls can be used where the decision is made based on performance indicators, such as pH, concentration, bacteria counts, mold counts, oil contamination or other measurements. The user must decide how and when to treat or dispose of exhausted fluids. For disposal purposes, spent metalworking fluids are commonly considered oily wastewater.

When selecting a waste treatment method, there are a number of considerations that need to be taken into account. Typically, these will include:

- Hazardous vs. nonhazardous RCRA regulatory classification of the waste

- Volume of the waste

- Waste characteristics

- Availability of sewer disposal

- Availability and cost of contract hauling services

- Availability of waste treatment assistance

- Equipment, labor and chemicals required for onsite treatment

- Liability

- Cost

- Applicable pretreatment standards

RCRA is the Resource Conservation and Recovery Act, administered by U.S. EPA.

The primary disposal options for plants are contract hauling or treatment for sewer disposal. Used metalworking fluids become contaminated with oils, fines, metals, bacteria, etc. These fluids require treatment prior to disposal to meet local sewer discharge standards, which are subject to local, state and federal laws.

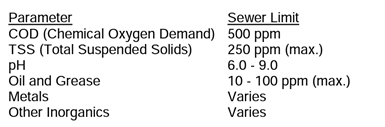

Chart 1. Typical effluent standards. Photo Credit: Cimcool Fluid Technology

Sewer discharge standards restrict pH, oil and grease, solids, metals and other components. Effluent standards vary from place to place; however some typical criteria can be seen in Chart 1.

For small-quantity generators of oily wastewater, typically contract hauling or evaporation is the most effective and economical disposal method. There are national, regional and local contract haulers, and they can be found in a business telephone directory or by calling the fluid service provider. A certified hazardous waste hauler is required to haul and treat hazardous wastes, per RCRA standards and guidelines.

Liability is a very real issue and affects any business that generates, transports, stores, treats or disposes of waste. It is important that each step of the treatment and disposal process is completed in an ethical and legal manner, and in every case, the most effective methods for treatment and disposal must be employed fully in order to minimize any future liability exposure.

Physical Treatment

Various physical treatment methods are used effectively to treat metalworking fluids for disposal. Evaporation is a common treatment for low to moderate volumes of oily wastewater (25 to 3,000 gallons per day). This method is very effective and uses heat to evaporate water from the used fluid and to concentrate the oil. Thus, sewer discharge is avoided; however, air discharge permits may be required.

Another common physical treatment method is membrane separation, of which there are two types — ultrafiltration (UF) and reverse osmosis (RO). UF uses a membrane to separate oil and large molecular weight material from the water to provide an effluent of generally acceptable quality for sewer discharge. UF is very good at removal of oil and grease and suspended solids, but typically is ineffective for removal of dissolved solids. UF is used for wastewater volumes from approximately 50 to 15,000 gallons per day, and provides a relatively simple and consistent process to treat oily wastewater.

For plants needing further improvements in effluent quality, a secondary treatment using RO can be used. RO is a separation process similar to ultrafiltration, but using higher pressures and tighter semipermeable membranes. This reverses the natural process of osmosis, causing water to flow from the more concentrated to the more dilute solution side of the membrane. Continuing membrane developments offer various pore sizes, membrane materials and configurations to optimize oily wastewater treatment and disposal. The effluents from either UF or RO typically are not reused. Incineration may be used for final treatment of oily concentrates and hazardous wastes.

Chemical Treatment

Chemical treatment uses various inorganic chemicals (for example, aluminum sulfate or ferric chloride) or organic chemicals (for example, cationic or anionic polymers) to destabilize or break emulsions of used oily wastewater.

Chemical treatment can be used for volumes of wastewater from fifty gallons per day to more than a million gallons per day; however, it is generally understood that chemical treatment is more cost-effective for producers of larger volumes of oily wastewater. A byproduct of chemical treatment is a sludge or oily waste concentrate that requires further treatment for oil recovery. Further, chemical treatment is effective for treatment and removal of metals in oily wastewater.

Biological Treatment

The high organic content of most metalworking fluids makes them good candidates for degradation by bacteria for waste treatment. However, the high oil content of these fluids typically eliminates using biological treatment as the primary treatment method. Thus, a chemical or physical treatment process almost always precedes the use of biological treatment for metalworking fluids. However, biological treatment is an excellent secondary or tertiary treatment of metalworking fluids for organics reduction. Again, as is the case with chemical treatment, this process is most economical for large users, and especially in cases where there is not an option for sewer discharge.

Summary

With today’s greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are a consumable product and have a finite life. By nature, they must be treated and disposed. However, the selection of a treatment or disposal method must be based on a number of factors, including not only the volume to be treated, but also other wastewater characteristics. And it bears special emphasis that any and all fluid treatment and disposal methods must comply with applicable local, state and federal regulations.

Related Content

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreForces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreRead Next

How to Choose and Size the Right Metalworking Filtration System

Understanding the importance of a properly engineered filtration system to the mold build process.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)