March Cutting Tool Orders Highest in 13 Months

March cutting tool orders reached $177.6 million, which Gardner Intelligence says is close to a normal, pre-lockdown level. Starting in April, rapidly accelerating growth in the rate of change is expected.

According to the Cutting Tool Management Report (CTMR) for March 2021 from the Association For Manufacturing Technology (AMT, McLean, Va., U.S.), real cutting tool orders were $177.6 million, which was easily the highest order total since March 2020. Also, cutting tool orders were down just 4.5% compared with one year ago, which was the slowest rate of contraction since December 2019. Since cutting tool orders in March 2020 were at a normal, pre-lockdown level, the rate of change in 2021 indicated that cutting tool orders were essentially back to normal levels. Starting in April, the month-over-month comparisons will get much easier and the rate of growth will accelerate dramatically. The annual rate of change, -27.0%, contracted at a decelerating rate for the first time since it started contracting in October 2019.

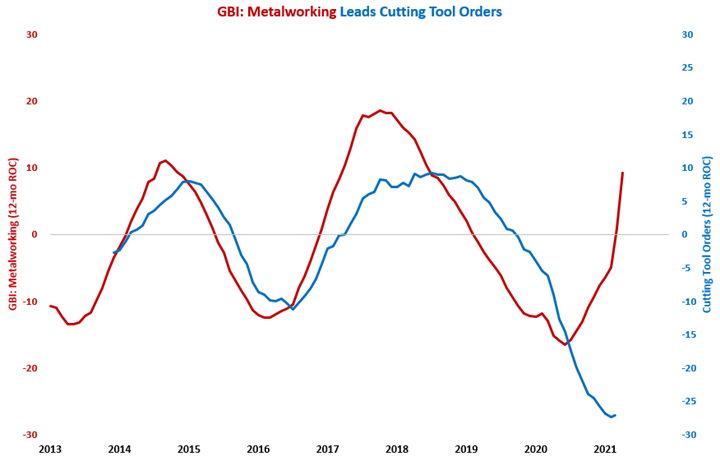

The GBI: Metalworking is a good leading indicator of cutting tool orders and leads cutting tool orders by seven to 10 months. In April, the index was above 50 for the seventh month in a row and the month-over-month rate of change in the index grew for the ninth consecutive month and April’s rate of growth was the fastest since May 2010. The annual rate of change grew at an accelerating rate for the second consecutive month, indicating that the annual rate of contraction in cutting tool orders should be at a bottom.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)