Cross-Functional Team Key to Customer Service, Complexity and China Partnership

Michiana Global Mold uses a cross-functional team of journeymen moldmakers and engineers to improve customer communication, service, and quality.

Share

Read Next

Who is Michiana Global Mold?

Kelly Kasner, Director of Business Development: Since 1964, Michiana Global Mold (MGM) has been a designer and builder of plastic and rubber injection molds for the automotive, medical, industrial and consumer products markets. We specialize in parts with Class A finishes, high complexity and multiple materials.

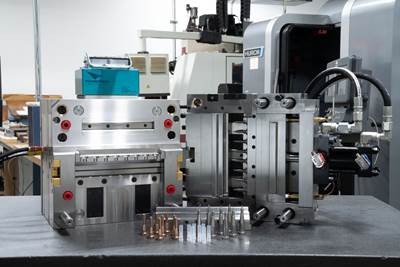

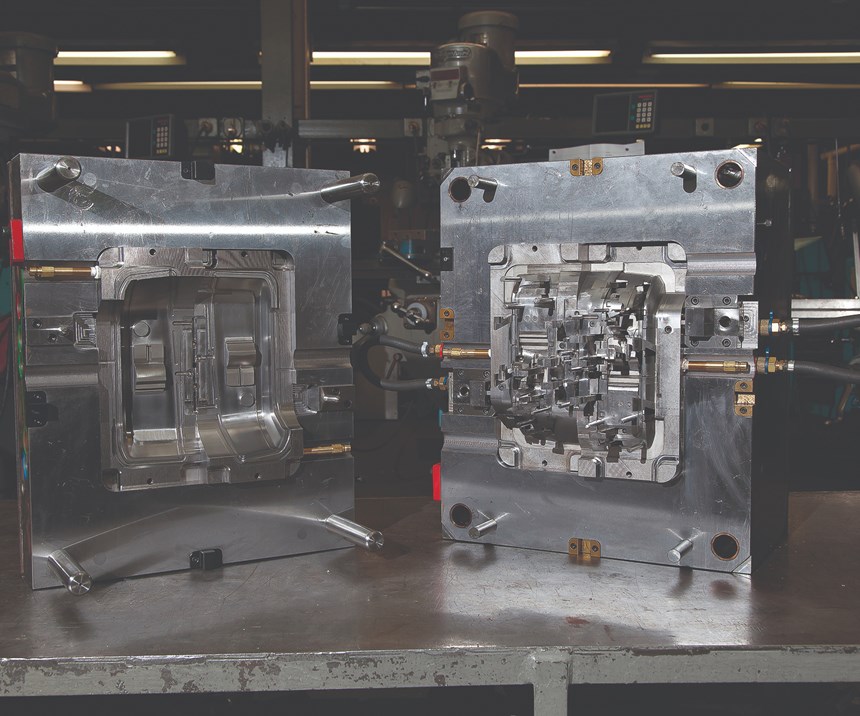

Our cross-functional design and engineering team works in collaboration with our certified journeyman moldmakers to build tight-tolerance, single to high-cavitation molds with hot/cold runners, collapsible cores, inserts and over-molding, as well as shuttle, stack, unscrewing, two-shot and rotational molds. MGM is an ISO:9001-certified, AMBA and NTMA member.

How does MGM produce production-ready parts the first time?

Kasner: MGM’s up-front investment in effective communication with the customer, a thorough understanding of the part and molding process, and adherence to mold standards and quality systems for more than 50 years makes delivery of production-ready parts the first time possible. Our cross-functional teams, which include program managers, production managers, designers and leadmen, who are all journeymen moldmakers, partner with the customer and use a design-for-manufacturing approach to design and build a quality tool to mold each specific part. We use the latest in software and equipment (Unigraphics 3D software and both manual and high-speed machines).

Why is it important that all of MGM’s mold designers originate as journeymen moldmakers?

Kasner: Our mold designers typically have an associate degree in tool and manufacturing technology or plastics engineering technology with five to eight years of experience in the field. They are also expected to be strong in problem-solving, operation monitoring, CAD/CAM and moldmaking equipment, and possess a mathematical aptitude and critical thinking skills. These qualities allow our in-house designers to easily collaborate with our program engineers and mold builders to develop tooling and systems to optimize production, efficiency and reduce downstream manual processes.

Can you define the high level of expertise that is needed to take on complex molds?

Kasner: Our team comprises experts who can address complicated injection options, cooling issues, water lines and gate placement because MGM is well-known in the industry for designing and building ‘non-standard’ molds (not the standard ‘open-and-shut’). Our niche in the marketplace is building complex injection molds with more moving features, tighter tolerances, multiple and buried cams, hydraulics, split parting lines and delayed/multiple ejections. The majority of our moldmakers and engineers have decades of experience, and our corporate culture offers continuous professional and technical development.

Describe your Chinese partnership? How did you find and develop this partnership, and why? How has this partnership benefited Michiana?

Kasner: MGM is considered a pioneer in China with partnerships spawning over a decade. In 2008, our management team recognized the increased global competition in China and their presence in the U.S. market. Although we recognized the disparity of quality standards, the origin of component issues and a sub-standard workforce training culture, we also discovered companies in China that were motivated to adopt an Americanized culture and related quality standards.

Over several years, our team commenced a process of working with nearly one-hundred shops in China before it found the right company with which to partner. This partnership has driven continued success stories at MGM as we can maximize cost savings using the Chinese labor market while delivering U.S. quality standards in mold design and build.

We use only North American or German steels and components in our Chinese mold builds. All tools include mold-flow analysis and on-premises sampling. Our molds built in China are fully backed and managed by our U.S. team. MGM needs to offer this option when partnering with companies to meet their tooling needs with maximum cost savings without compromising quality, in addition to local service and local support once their tool reaches the U.S.

Can you share any tips or lessons learned for developing and working with a Chinese partner? What is the key ingredient in this partnership?

Kasner: The key is to invest in your Chinese partnership as much as you would in your home team. Take time to form a trusting relationship, invest in the management and workforce talent, and use technology to increase capacity and capabilities. Although a mutually beneficial partnership also includes respect of both U.S. and Chinese heritages, take the time to invest in incorporating an American craftsmanship culture.

The key ingredient is communication. An in-house engineer dedicated to managing our global programs, who is engaged with our customer and our China team in effective and continuous communication, is critical to the success of our mold build programs.

How do you achieve effective and close communication with customers?

Kasner: Communication experiences are an integral part of MGM’s success strategy in developing relationships, not just making sales. Our repeat and loyal customers learn to expect intimate communication, which involves part and design meetings, phone calls, site visits, progress reports, shared files, material certifications, post-delivery support and service. Each team member is responsible for customer service, cultivation, discovery and awareness. MGM opened in 1964 as a family business focused on quality craftsmanship, innovation and customer service, and that family culture still exists today.

Related Content

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreRead Next

Experience, Knowledge Base, and Creativity Give Tri-Par An Edge in Molds for High-Flow Material Parts

Expertise in building molds for parts made from highly-engineered materials and automation for molding gives Tri-Par Die and Mold Corp. key mechanisms for growth.

Read MoreA 'Quality Without Compromise' Mindset and A Diverse Customer Base Gives Delta Mold More Peaks Than Valleys in Business

Quality-driven processes and focus on diversity in the markets served are key to Delta Mold’s continued success.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)