Automated Access to the Right Cutting Tools

An essential part of any automated moldmaking operation is being able to access the right cutting and maintenance tools.

An essential part of any automated moldmaking operation is being able to access the right cutting and maintenance tools. However, there’s a complicating factor: in manufacturing, few indirect materials have as much cost associated with them as cutting tools.

How can management provide needed access and maintain control at the same time? Traditionally these needs have been at odds with one another and provisioning technicians has primarily occurred in two ways: the locked cage or the open door.

1. The Cage: Materials are kept in a tool crib where they are handed out by a crib attendant and transactions are manually recorded. Issues with this include closed access for 2nd and 3rd shifts depending on staffing, increased hoarding of materials, and worst-case scenario: work stoppage due to lack of materials and inaccurate accounting for materials use.

2. The Open Door Policy: The alternative is leaving the cutting tools in an open environment where employees have access carte blanche to all materials, including ones they may not need. The inefficiency of this option is obvious to any manager who has dealt with stock-outs or increased costs when materials are unaccounted for.

Clearly, with these options there is a huge expense that is either lying unguarded on the manufacturing floor for anyone to take or locked in a tool crib with limited access. There is also another important inefficiency intrinsic in either option: both require employees to leave their work areas to locate the materials. There is a better way.

Putting the Right Materials Next to the Technician

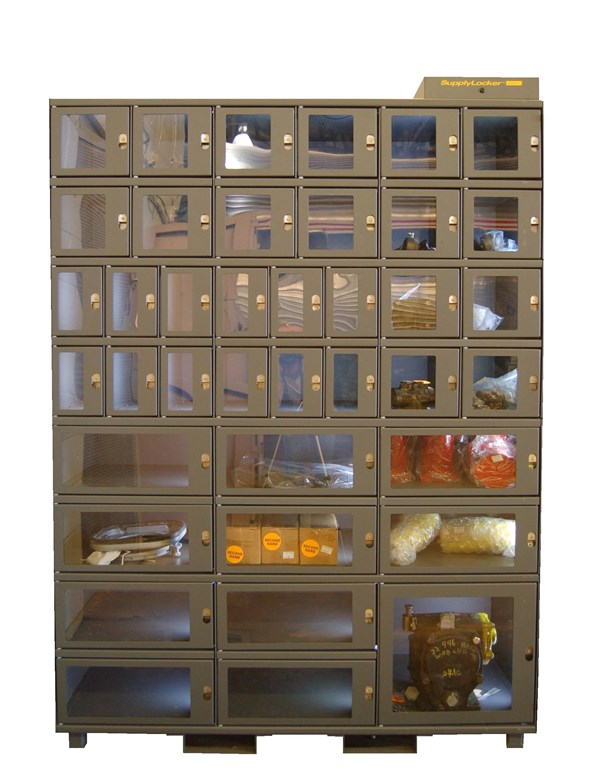

Point-of-use solutions put required materials exactly where they are needed at the work cell, while ensuring that the right materials are used and providing full accountability for each transaction. Employees no longer have to wander the manufacturing floor wasting valuable time retrieving materials, or even worse, incurring machine downtime with loss of production.

Point-of-use solutions are ideal for dispensing expensive cutting tools and safety materials. With a simple swipe of badge and item selection, the operator has the materials needed in a transaction that takes seconds over one that could have taken 20 minutes just in travel time to a central store. Employee productivity increases and the chance of a critical work stoppage is significantly reduced.

Additionally, regular maintenance of moldmaking machinery is required. When servicing is needed, the point-of-use devices can be used to check-in and check-out the required maintenance tools. If a tool is already checked-out to another attendant the device screen indicates who has it, so it can be located quickly. Time limits can be used. If a tool is not returned in the allotted timeframe an e-mail is automatically generated and sent to supervisors who can then track down missing tooling.

Tool repair and replacement costs drop and total tool loss become nonexistent. Also maintenance repair costs may be tracked by machine number, department or cost center to provide visibility to the on-going service history of machinery located throughout the plant.

Putting Materials Intelligence to Work

Production efficiencies and cost savings gained from point-of-use devices are two important benefits of the solution. But there’s greater benefit to be gained, especially in operations where LEAN and Six Sigma initiatives are a priority. The full point-of-use solution includes robust capabilities that allow management in these operations to: integrate with existing ERP systems (often as standard offering); enable purchase standardization compliance across plants from core suppliers; provide enterprise-wide data visibility for all business units with local databases; deliver significant cost savings ranging from 20 to 50 percent; eliminate or reduce excess inventory and waste; and, provide accountability and costing at the point of use for tooling usage for individual tools and complete tool setups.

Contributor:

David J. Simbari serves as President and Chief Executive Officer of SupplyPro. David brings 20+ years of sales-oriented leadership positions in the industry, which combined with his broad-based knowledge of supply chain management, makes him an ideal person to lead SupplyPro. David is the former chairman and chief executive officer of OPTUM Inc., a White Plains, New York-based provider of supply chain and warehouse management software. He held that position for seven years, until OPTUM was acquired by Click Commerce Inc. in 2005. Prior to OPTUM, David spent five years with Industri-Maternatik ("IMI"), a Swedish provider of complex order management systems for consumer package goods companies, first as president of North American operations and later as senior vice president for worldwide sales and marketing. Before IMI, he served as vice president of North American sales for Ross Systems, a leading provider of application software products for the finance, human resources, process manufacturing and logistics markets.

For More Information:

SupplyPro

(513) 671-4933, ext. 107

www.supplypro.com or call

Related Content

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.png;maxWidth=970;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)