March 2001 Issue

March 2001

Features

Featured articles from the March 2001 issue of MoldMaking Technology

Designing Plastic Components and Injection Molds for Robotically Dispensed Foam-in-Place Gasketing

While robotic technology improves design flexibility and productivity, up-front attention to component and mold design can lead to even higher gains

Read MoreManagement Session for Moldmakers

Fortifying your vision for success in the changing global economy is essential to achieving total quality management. And if everyone from management down makes a concerted effort, TQM is a goal that any moldmaking shop can achieve.

Read More

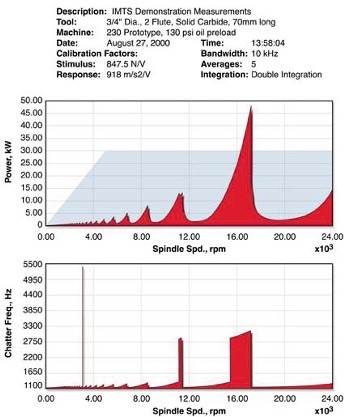

Spindle Design for Maximum Performance

Understanding the influence of all the forces - from the type of insert to the machine base - is the key to maximum spindle, and thus, maximum machine tool utilization.

Read MoreHow to Achieve Intelligent Tool Management

With an effective tooling database, moldmakers can manage and track the information that is essential to their business.

Read MoreThree Steps to a Diamond Finish

Ultrasonic profilers can be a great time saver. One veteran polisher recounts his step-by-step procedures and thoughts as he tackles one of the tool and die industry's toughest problems - intricate rib work combined with an impossibly short delivery time

Read MoreEnvironmental Safety for Moldmakers

Compliance with environmental and OSHA regulations are not always easy, as it involves consistent effort to establish and maintain programs to ensure the health and safety of your employees.

Read MoreFilling the Employment Gap With Women

As we enter the 21st century, the Bureau of Labor Statistics reports that the science, engineering and technology fields will grow at such an alarming rate that by the year 2008 there will be 5.3 million newly created jobs in these fields.

Read MoreMoldmakers' Catch 22

A new survey released by CIMdata shows, among other things, that new and faster technology is shaping the moldmaking shop of tomorrow both here and abroad.

Read MoreWorking On My Business: Structural Diversity Enables Nimbleness

Strategies for diversity can pay big dividends. The second part of a three-part series, this article illustrates how diversity of structural capital can be used to create profit.

Read MoreOn the Right Path - A Case Study

An off-line programming system allows a moldmaker to streamline electrode and multi-cavity mold production.

Read MoreBlowing the Competition out of the Water

The members of MoldMaking Technology's Editorial Advisory Board share their thoughts on how American moldmakers can attempt to combat overseas competition.

Read MoreCraftmanship in the Toolroom

Every toolroom would like to operate with a full complement of journeymen toolmakers; however, true craftsmen are tough to come by. There are steps you can take to train your employees in achieving a higher level of craftsmanship.

Read MoreSolids Data Exchange: Anything But

Solid modeling appears to be the technological hurdle the industry faces today. Moldmakers are discovering that although there are many benefits to utilizing solid modeling, the translations aren't always what they should be.

Read MoreService With a Smile

Suppliers are thinking of innovative ways to expand customer service programs - offering total support for a machine tool's lifespan.

Read MoreCommercial Tooling Methods

A new, patented toolmaking method - Customer Moldmaking Process Technology (CMPT) - provides a cost-effective alternative to traditional toolmaking methods.

Read MoreReverse Engineering: An Overview of the Options

The reverse engineering industry has come a long way in recent years and there are many options currently available that can be scheduled into a planned project with predictable and cost-effective results

Read More