Environmental Safety for Moldmakers

Compliance with environmental and OSHA regulations are not always easy, as it involves consistent effort to establish and maintain programs to ensure the health and safety of your employees.

The environmental compliance issues related to EDM operations are primarily involved with the proper management of wastes; however, SARA Title III - Community Right to Know, the OSHA Hazard Communication Standard and the OSHA air quality regulations also may impact EDM operations.

Waste Management

The first step that should be taken in developing a waste management program is to identify all of the waste streams from the EDM operation. Under most circumstances these would include wire, deionizing resins, oils, filters and water. Then you must determine whether or not the material is actually a waste. This concept can be applied to the wire from the EDM operation. If the wire is sent to a scrap yard for reclaim, it would not be considered a waste. However, if it was placed into the trash dumpster, it would be considered a waste and a hazard determination would be required. This concept also can apply to the resins. If they were sent for regeneration, they would not be considered a waste. If they were sent for disposal, then a hazard determination would be required. If the material is determined to be a waste, it would fall into one of the following three waste categories: solid waste, state-regulated waste or hazardous waste.

A hazard determination must be conducted on each waste stream to determine which category applies to the particular waste stream. Material Safety Data Sheets may be used when conducting the hazard determination, but laboratory analyses will most often be required for EDM wastes, for once they have been used, they do not maintain the same characteristics as the virgin product.

Hazardous Wastes

The first step in conducting a hazard determination is to establish whether or not the waste stream is a hazardous waste. This waste stream should be compared to the listed wastes included in the hazardous waste regulations - 40 CFR 261.31. These wastes are from non-specific sources such as degreasing operations using chlorinated solvents like trichloroethylene; or flamm-able and toxic materials such as acetone, methyl ethyl ketone, toluene and xylene. While it is unlikely that the wastes from an EDM operation would be included in the listed wastes, these lists may include materials used in other operations that are ancillary to the EDM operation, such as degreasing or painting.

The waste stream must then be compared to the characteristics of a hazardous waste in 40 CFR 261.21-24.

- Ignitability - flashpoint <140xF;

- Corrosivity - pH equal to or less than two or equal to or greater than 12.5;

- Reactivity - containing reactive amounts of cyanide or sulfide; and,

- Toxicity - exhibiting levels of metals, solvents or pesticides after a Toxicity Characteristic Leachate Procedure (TCLP) above the limit established in the regulations.

The contaminants included in the toxicity characteristic are metals, solvents and pesticides. The types of metals that are included in the TCLP characteristic are arsenic, barium, cadmium, chromium, lead, mercury, selenium and silver. While these specific metals may not normally be considered part of the EDM process, stainless steel may contain significant amounts of chromium and leaded steel may contain high levels of lead.

The TCLP (for metals and solvents) should be conducted at least once on all waste oils, filters and resins from EDM operations that are being sent for disposal. Wastewater that is containerized and sent off-site for disposal also should be analyzed for the presence of the eight hazardous waste metals and the TCLP solvents. Wastewater that is discharged to a sanitary sewer system will require a different type of analysis, which is discussed in the section on wastewater discharges.

State-regulated Wastes

In most states, a waste that is not a hazardous waste will be a state-regulated waste. These vary by state, but most often include PCBs, petroleum oils, water-soluble oils and chemical waste liquids and chemical waste solids. The manufacturer should be aware that in some states, wastes are defined as hazardous wastes when in other states they are not - i.e, Massachusetts defines waste petroleum oils as hazardous wastes, while Connecticut requires the handling of waste oils as a state-regulated waste.

The requirements for handling state-regulated wastes may vary by state, but most states require the storage of state-regulated wastes in a manner that protects the environment and the disposal of state-regulated wastes by facilities that are permitted to handle such wastes. Often these wastes also must be transported by a licensed, state-regulated waste hauler.

Solid Wastes

Most states will not allow the disposal of liquids, industrial materials containing liquids or industrial materials containing hazardous substances in solid waste landfills or in solid waste incinerators. There may be some exceptions to this prohibition, but this should be checked with the state environmental protection agency before industrial materials are disposed with the sanitary wastes.

Proper Handling of Hazardous Wastes

Once the hazard determination has been conducted, the company must establish a waste management program to insure the proper handling of the hazardous wastes. The handling requirements for hazardous wastes vary by the amount of hazardous waste that is generated in any given month. A conditionally exempt, small quantity generator (one who generates less than 100 kg of waste per month) must conduct a hazard determination, store the wastes in a manner that protects the environment and send the waste to a permitted hazardous waste disposal facility.

A small quantity generator generates between 100 kg and 1,000 kg of hazardous waste per month, and must conduct a hazard determination, store the waste in a manner that protects the environment; store the hazardous wastes on-site for a period of time that does not exceed 180 days; post emergency response telephone numbers near telephones; insure that employees understand the emergency response procedures; insure that the waste is transported by a licensed hazardous waste transporter; use a hazardous waste manifest to accompany the waste while it is being transported on public roadways; and send the waste for disposal to a permitted treatment, storage and disposal facility.

A hazardous wastes generator generates more than 1,000 kg of wastes per month. In some states this also includes having that amount of waste on-site at any given time. A generator must follow all of the same requirements that were listed for small quantity generators - with the exception that the generator may store hazardous wastes on-site for a period of time that does not exceed 90 days.

A hazardous wastes generator also must develop a contingency plan that describes what actions should be taken if a release of a hazardous waste occurs, send copies of the contingency plan to state and local emergency response agencies and conduct annual personnel training for all employees involved in the management or handling of hazardous wastes. Generators also must develop job descriptions for the jobs associated with hazardous waste management or handling and compile a list of hazardous waste employees who fill those jobs.

Hazardous wastes must be stored in a hazardous waste storage area that has been provided with: (1) a floor that is impervious to the wastes that will be stored there; (2) secondary containment that will not allow a release to escape into the environment; (3) security to prevent unauthorized entry; and, (4) warning signs. The hazardous waste storage area must be inspected on a weekly basis with an inspection log used to document the inspection. This inspection log must be kept on file for at least three years.

All containers of hazardous wastes must be in good condition without any evidence of bulging, denting or corrosion and they must be able to be closed tightly. The containers must be kept closed at all times unless waste is being added to the container.

Hazardous waste containers - regardless of size - must be provided with a hazardous waste label that states the name of the waste and the accumulation start date. Department of Transportation hazard class labels also should be used to identify the hazards associated with the waste in the container.

Hazardous waste manifests must accompany all shipments of hazardous waste. They contain the shipping papers that are required by the Department of Transportation and must contain all of the required information. The completed manifests must be kept on-site for at least three years - although most companies will keep the manifests on file for the life of the company.

It is important to note that a generator is responsible for the wastes generated at its company for the life of the waste. This has been called "cradle-to-grave responsibility," which means that if a waste is sent to a disposal facility and that disposal facility mismanages the waste in a manner that contaminates the environment and the facility cannot afford to clean up the contamination, all generators who sent wastes to that site will be called in by the U.S.

Environmental Protection Agency (EPA) to assist in the remediation of the site. Most companies are now attempting to limit this liability as much as possible by reducing the amount of wastes generated by their company or, if possible, eliminating them entirely.

Wastewater Management

Under Federal and most state regulations, all industrial discharges of process wastewater must be approved by the state environmental protection agency. These regulations apply to all treated wastewaters and any process wastewaters that are discharged to the ground, surface waters or a publicly owned treatment works (POTW).

In many states non-contact cooling water also must be permitted under the regulations. Under most circumstances, the non-contact cooling waters will not be allowed to be discharged to the POTW. The preferable method of disposal would be a discharge to the ground or a nearby body of water - provided that the contaminants in the water are at an acceptable level.

Before discharge, the wastewaters must be treated to meet the effluent limitations set by either the Federal or state agencies. The contaminants of concern include - but are not limited to - oils, metals, solvents, pH and particulates.

The permitting process requires:

- Identification of all wastewater-generating processes and the determination of the contaminants and their levels in each waste stream.

- Design and installation of a treatment system, which can reduce the contaminants to below the effluent limitations.

- Submission of an engineering report and permit application to the state regulatory agency.

- Continued monitoring of the treatment process and analysis of effluent to insure ongoing compliance with the effluent limitations.

OSHA Hazard Communication Standard

While not an environmental regulation, a discussion on the handling of hazardous materials and wastes would not be complete without a discussion of the requirements of the OSHA Hazard Communication Standard - one of the most often cited violations of the OSHA regulations when an OSHA inspection is conducted at a manufacturing facility.

The OSHA Hazard Communication Standard applies to any business or industry in which a hazardous material is in use. This includes, for example, manufacturing, dry cleaning, gasoline stations, printing, photographic developing and dental offices. This standard applies to industrial/chemical materials that present a physical or health hazard to employees. There are a number of chemical classifications/hazard characteristics that are mentioned in the regulations, including carcinogens, toxins, flammable liquids, reactive materials, oxidizers, corrosives and irritants. For the purpose of this general overview of the regulations, suffice it to say that any industrial material that is included in one of the aforementioned chemical classifications and/or that has an established Permissible Exposure Limit (PEL) or a Threshold Limit Value (TLV) should be included in the program. Chemicals, paints and thinners, metals, gases, solvents, welding materials, oils and coolants are all included.

The Hazard Communication Standard (29 CFR 1910.1200) requires that a company develop a written Hazard Communication Program. This program must include:

- A method for determining the hazards to which employees are exposed in the workplace.

- A method for obtaining Material Safety Data Sheets (MSDSs) for all materials currently used on-site and any that are brought on-site in the future, including samples.

- Filing procedures that insure that the MSDSs are kept up-to-date and are readily available for review by employees.

- A method for informing outside contractors of the hazards to which they and their workers may be exposed while working at the manufacturing facility.

- Procedures for determining the hazards of non-routine tasks.

- Standard operating procedures for insuring that all containers are properly labeled with the name of the chemical and the hazards associated with its usage.

- A personnel training program that provides the necessary information to current employees and to new hires before they are exposed to hazardous materials.

The employer must post a sign notifying employees of the existence of the written hazard communication program, the location of hazardous materials in the workplace and the location of the MSDSs for the hazardous materials to which they are exposed in the workplace.

OSHA Air Quality Regulations

The OSHA regulations require that a company review its operations to determine if there is the potential for over-exposure to any hazardous materials used in the manufacturing operations, due to airborne contaminants.

With EDM operations, concern has been expressed over the possibility of releasing metal oxides into the workplace atmosphere. It is unlikely that this would occur, due to the fact that all cutting of metal in EDM operations occurs in either oil or water. This does not allow the metal oxides to be released to the atmosphere - rather, they would be captured in the liquid.

The release of smoke into the workplace atmosphere also may be an area of concern. When cutting small metal parts, the release of smoke into the atmosphere would not present a problem. Smoke that is released during the cutting of large metal parts may present a concern.

If company personnel are concerned with the possibility of the release of metal oxides or smoke into the workplace atmosphere, air quality monitoring should be conducted to determine the level of exposure to the metals of concern or smoke in the workplace.

Clean Air Act

The Clean Air Act applies to companies in which there is the potential for the release of contaminants into the atmosphere. These contaminants include nitrous oxides, sulfur dioxides, particulates, volatile organic compounds and hazard air pollutants. The emission levels that would apply to EDM operations would be for particulates and metals, which are listed as hazard air pollutants. A company would be required to obtain an operating permit if it is emitting more than 50 tons per year of particulates or 10 tons per year of any regulated metal, or had the potential to emit that amount if the operations were conducted 24 hours per day, 365 days per year.

SARA Title III - Community Right to Know

SARA stands for the Superfund Amendments and Reauthorization Act, and Title III of the Act details the process by which information on the hazardous materials used at a facility must be provided to the community in which the manufacturing facility is located. The state and local governments are required to develop emergency response plans, which describe the steps that would be taken should a release of a hazardous material occurs.

Manufacturing facilities are required to provide information to state and local emergency planning committees on materials that are on the List of Extremely Hazardous Substances and are used on-site in amounts that exceed the Threshold Planning Quantities listed in the regulations. They also must provide information on the OSHA-regulated substances that are on-site in amounts that exceed 10,000 pounds.

None of the materials used in the EDM process are on the List of Extremely Hazardous Substances. It is the responsibility of each manufacturer to determine if there are any OSHA-regulated chemicals on-site that exceed the 10,000-pound reporting limit.

A Tier II Inventory Form must be filed annually on or before March 1 each year, if the company is notified of the existence of materials on the List of Extremely Hazardous Substances. This form provides information on the type and amount of materials at the site and the type and location of the containers in which they are stored. A site plan noting the location of the hazardous materials also must be submitted.

SARA Title III also requires the reporting of the release - to air, soil or water - of any material on the Section 313 list of substances (also known as the Form R List). This list includes chlorinated solvents, petroleum solvents and metals. If, in one year, a company uses more than 10,000 pounds of a manufacturing aid - such as a chlorinated solvent used in degreasing - or 25,000 pounds of a material that is included in the product - such as chromium, lead or nickel, which would be contained in the metal being processed in the EDM operation - then a Form R must be filed on or before July 1 of each year. The Form R provides information on the amount of the material that has been released, the location of the release and the manufacturing operation that created the release.

Due to the fact that EDM operations are conducted with either water or oil, there should not be a release of any of the metals that are being processed. Thus the Form R reporting requirement would not apply. If air quality monitoring does indicate the release of metals to the workplace air and the company uses more than 25,000 pounds of a listed metal, then the company would be required to submit a Form R.

Compliance with all of the environmental and OSHA regulations that apply to EDM operations is not a simple task nor is it a one-time effort that does not require repeating. It requires an ongoing effort to establish and maintain programs to insure continued compliance, so that the company ensures the health and safety of employees and the well-being of the environment.

Related Content

Kitting Cart Enhances Material, Component Handling Capacity

The Creform System features a custom five-level shelf section with pullout drawers to easily and safely transport materials, components and other devices through a warehouse or facility.

Read MoreSpotting Press Facilitates Safe, Productive Adjustment, Inspection and Repair of Molds

Millutensil highlights its specialization in mold and die spotting presses for mold validation, equipped to meet the needs of the operator when accessing or adjusting the mold.

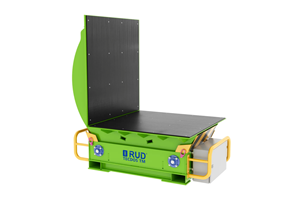

Read MoreIndustrial Drive Technologies Support Moving, Rotating Molds of All Sizes

RUD Tecdos solutions within its Mold Handling Solutions portfolio manage horizontal, vertical and rotational drive solutions for all environments.

Read MoreNew Tool Breakage Alarm System Mitigates Machining Damage

If a cutting tool breaks or compressor malfunctions the Tool Breakage Alarm from Air Turbine Tools alerts operators, or stops the program altogether.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)