Machining

YCM Alliance Technical Center Grand Opening Highlights Customer-Centric Focus

The two-day event celebrated at the end of May brought in 300+ OEM and job shop customers, dealers and industry vendors for mold/die, general parts and high-speed machine demonstrations as well as industry expert presentations.

Read MoreNew Michigan Technical Center for YCM Alliance

YCM Alliance held a grand opening of its new Technical Center in Sterling Heights, Michigan, last week, which is the first in a series of centers designed to showcase and demo machining solutions for die and mold machining, ultra-high-speed machining and general parts machining.

Read MoreMold Care, 3D Scanner Best Practices, the State of Maintenance & More Most-Viewed April Content

April held a little bit of everything for MoldMaking Technology. From mold care and maintenance to 3D scanner and printing best practices, take a look at what might have missed your radar.

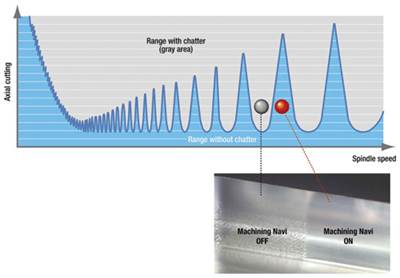

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreStability, High Speed, Flexibility of Five-Axis Portal Milling Machine Reduces Rework for Mold Builder

The thermo-symmetrical construction of a five-axis portal milling machine with a center-guided Z-axis enables higher accuracy, reducing rework. Also, the symmetrical design and the guide arrangement increase stability and save weight, making the machine more dynamic, productive and energy-efficient.

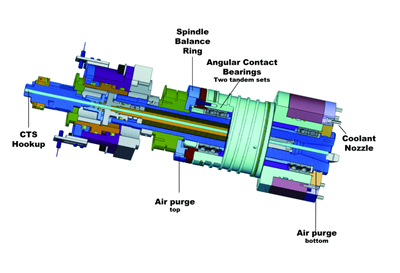

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreFive-Axis Machining Center Permits Optimal Mold/Die Milling

Horizontal spindle position, maximum stability, tunnel concept, a large swivel range and versatile material cutting drive increase productivity in the Grob Systems G5550 Generation 2 machine.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

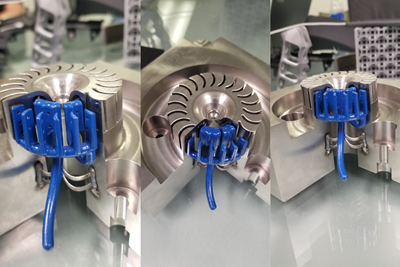

Read MoreHigh-Speed Milling Chucks Enable Heavy-Duty Milling

Big Daishowa Mega 12DS power chucks provide users with a highly stable and rigid operation when milling workpieces such as molds.

Read More