Hot Runners

Second-Generation Control Algorithm Elevates Mold Controller Performance

Husky launches a new control algorithm for its line of Altanium mold controllers, with 42% faster heat-up times, 30% less energy use and reported 64% increased productivity.

Read MoreMoldmaking Specialist Delivers High-Quality Shut-off Couplings, Flow Analysis Support

Hasco works closely in cooperation with partners like Müller + Sohn Kunststofferzeugnisse, serving more than 100,000 moldmaking-related products.

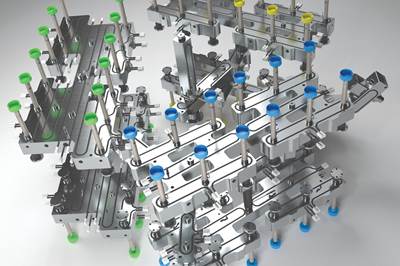

Read More2022 Sourcing & Technology Guide: Hot Runners

Hot runners deliver the material into the mold to make the part. These systems consist of hot halves, nozzles, gates and temperature controllers—all of which must be monitored, maintained and cleaned to guarantee a quality end product.

Read MoreController Cart Transports Hot Runner Control Units Closer to the Mold

Avoiding the risk of collisions or damage, the Hasco Co-Cart safely positions external control units nearer the injection molding machine, with additional storage space for common spare parts.

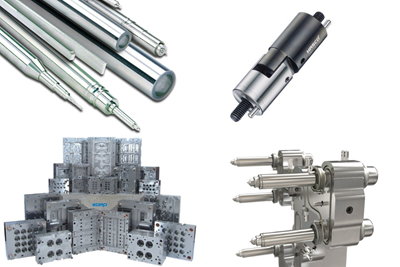

Read MoreEnhance Your Moldmaking Capabilities With These Hot Runner and Mold Component Products

MMT highlights new and improved innovations, including data collection devices, pins, bases, controllers, bushings, nozzles, positioning systems and much more.

Read MoreInternally Heated Sprue Bushings Optimize Melt Flow Control

Melt Design Inc.’s Equatemp Single Zone Hot Sprue Bushings are internally heated and feature a high purity ceramic insulator, replaceable thermocouple and predetermined wattage distribution.

Read MoreFlat Line Hot Runner Nozzles Save Space for Installation

Heitec Hot Runner Systems’ Flat Line Nozzles reduce the mold base size. According to the company, this configuration represents an ideal gate location.

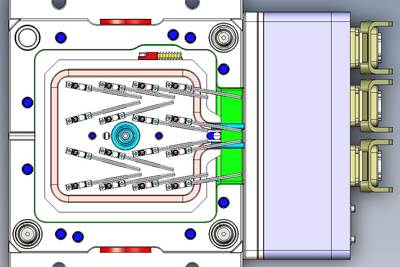

Read MoreThermally Sensitive or Corrosive Applications are Combatted by Hot Runners

Combined with Husky Technologies’ experience, guidelines and analysis tool, the company’s new UltraMelt hot runner technology meets the processing needs of challenging resins and demanding applications.

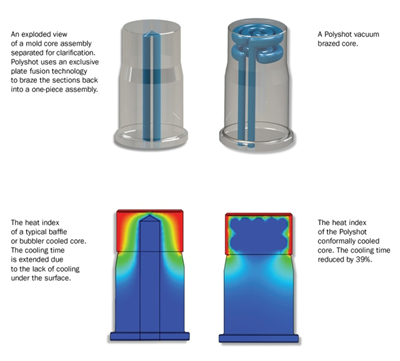

Read MoreVacuum Brazing Services for Conformally Cooled Mold Cores, Cavities

Polyshot’s Plate Fusion technology is able to reduce mold cooling time by as much as 60%, in addition to positively impacting mold cycle time, part quality and part repeatability.

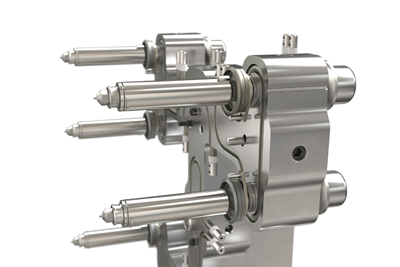

Read MoreHot Runner Temp Controller Detects Manifold Leakage

Mold-Masters has made leakage detection and monitoring an optional feature available on its TempMasters through installed thermocouples on the manifold.

Read More.png;maxWidth=970;quality=90)

_300x250 1.png;maxWidth=300;quality=90)